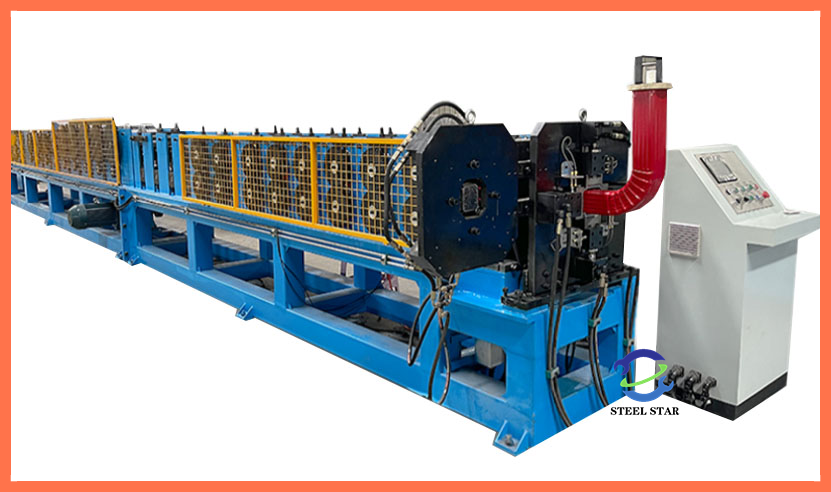

The Downspout Pipe Forming Machine: Channeling Precision in Rainwater Management

In the intricate system of a building’s exterior, efficient rainwater management is critical for structural integrity and longevity. The downspout, or rainwater pipe, serves as the essential conduit, channeling water from gutters safely to the ground or drainage system. The specialized equipment that manufactures these components—the downspout pipe forming machine—exemplifies precision roll-forming technology applied to a ubiquitous architectural element. This article explores its function, process, and significance.

Core Function and Output

A downspout pipe forming machine is a type of cold roll-forming line specifically engineered to produce the long, hollow sectional pipes used in residential, commercial, and industrial rainwater systems. Primarily working with pre-finished steel coils (galvanized, Galvalume, or color-coated) or aluminum, it transforms flat metal strip into consistent, high-quality pipes with various standard profiles, most commonly rectangular, round, or corrugated. Its primary output is the seamless, continuous production of downspout sections that are later cut to standard lengths for installation.

The Forming Process: A Step-by-Step Journey

The machine operates as a coordinated, in-line system:

- Decoiling and Leveling: The process begins with a coil of metal mounted on an uncoiler. The strip is fed into a precision leveling unit, which removes any coil curvature or stresses, ensuring perfectly flat material enters the forming section—a crucial step for final shape accuracy.

- Pre-Punching and Notching (Optional but Common): For many downspout designs, particularly rectangular ones with integrated connector ends, the flat strip passes through a punching station. Here, holes are created for future fasteners (screws/rivets), and precise notches are cut. These notches allow for the subsequent formation of interlocking seams or special folded ends that enable pipes to socket together seamlessly during installation.

- The Roll-Forming Mill – The Heart of the Machine: The prepared strip then enters a series of roll-forming stands. Each stand contains a set of hardened steel rollers with progressively shaped grooves. As the metal passes through, these rollers gradually bend the strip’s edges upward and finally form the complete pipe profile. The final stand closes the pipe’s longitudinal seam.

- Seam Closing and Locking: A critical stage follows forming. The machine employs a precise mechanism to join the longitudinal edges. For a lock-seam downspout, the edges are folded over and interlocked tightly, creating a strong, leak-resistant joint. Some machines may use a simpler stitch or spot-weld for certain applications.

- Cut-Off and Discharge: As the continuously formed pipe exits the seam-closing unit, a flying cut-off system (hydraulic shear or saw) activates. Synchronized with the pipe’s forward motion, it cuts the pipe to pre-set lengths (e.g., 10ft, 3m) without stopping production. Finished pipes are then conveyed to a stacking table or bundling station.

Technical Advantages and Design Considerations

The roll-forming process offers distinct benefits for downspout manufacturing:

- High Efficiency and Speed: It enables continuous mass production at rates far exceeding manual fabrication or press-brake methods, ensuring cost-effectiveness and supply reliability.

- Superior Consistency: Every pipe length produced has identical cross-sectional dimensions and seam integrity, guaranteeing predictable performance and ease of installation on-site.

- Material Strength and Finish Preservation: Cold roll-forming enhances rigidity while protecting the pre-appainted or metallic coating from damage, maintaining both corrosion resistance and aesthetics.

- Profile Flexibility: With interchangeable roll sets, a single machine can often produce multiple downspout sizes, shapes (e.g., transition from round to rectangular), and seam styles.

Machine design prioritizes rigidity to maintain dimensional tolerance under high forming pressure. The precision of the roller dies and the synchronization between the punching, forming, and cut-off stages are paramount. Advanced servo-drive systems ensure this coordination, allowing for quick changeovers and minimal setup waste.

Integration and Technological Evolution

Modern downspout machines are integrated manufacturing cells. They are controlled by Programmable Logic Controllers (PLCs) with Human-Machine Interface (HMI) panels, allowing operators to set length, quantity, and hole patterns easily. Many incorporate automatic stackers and bundlers. The latest advancements include in-line quality monitoring systems that check for seam integrity and dimensional accuracy, ensuring every pipe meets specification.

The downspout pipe forming machine is a testament to targeted industrial engineering. It solves a specific, high-volume manufacturing need with remarkable efficiency and precision. By reliably producing the vital components that protect buildings from water damage, this technology plays an unsung but crucial role in construction and architectural preservation. As building codes evolve and material science advances, these machines will continue to adapt, forming the durable channels that keep our structures dry and secure for decades to come.

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)