Bending Machine: The Versatile Artisan of Metal Fabrication

Across countless industries—from automotive and aerospace to construction and custom art—the ability to shape metal with precision is fundamental. At the core of this transformative process stands the Bending Machine, a versatile class of equipment that applies controlled force to deform sheet metal, plate, tubing, or structural sections into desired angles and forms. More than just a tool, it is the essential bridge between a flat design and a three-dimensional component.

What is a Bending Machine?

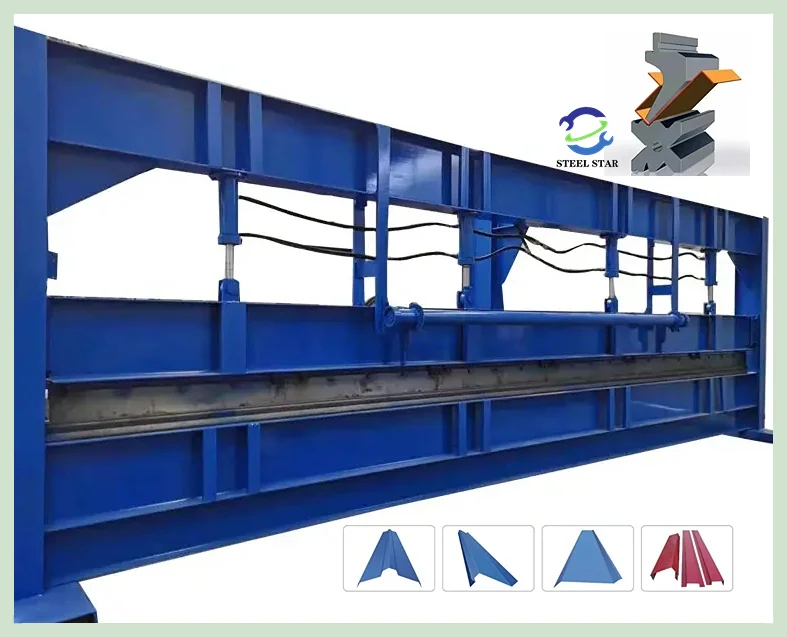

A bending machine is a machine tool that uses mechanical, hydraulic, pneumatic, or electrical power to apply force to a workpiece, typically metal, causing it to bend at a specific point along a linear axis. The process, known as press braking for sheet metal or simply bending for other forms, involves clamping the material between a matching punch and die to create a precise, repeatable deformation. Unlike cutting, the material’s structural integrity is largely maintained, making bending ideal for creating strong, rigid frames, enclosures, brackets, and structural elements.

Core Types and Principles

The functionality of a bending machine is defined by its method of force application and the type of workpiece it handles:

1. Press Brakes (for Sheet Metal & Plate):

- Mechanical Press Brakes: Utilize a flywheel and clutch mechanism to generate force through a ram. Known for high speed and efficiency in high-volume production of consistent parts.

- Hydraulic Press Brakes: The most common type in modern fabrication. Use hydraulic cylinders to power the ram, offering superior control over bending force, stroke length, and speed. They are highly versatile, capable of handling a wide range of materials and thicknesses.

- Electric (Servo-Electric) Press Brakes: Employ high-precision servo motors and ball screws to drive the ram. They are exceptionally energy-efficient, fast, quiet, and provide extreme accuracy, making them ideal for complex, precision work.

2. Tube and Pipe Bending Machines:

- Rotary Draw Benders: The standard for precision bending. The tube is clamped and drawn around a fixed die by a rotating form, producing tight, wrinkle-free bends with excellent repeatability. Essential for automotive roll cages, handrails, and furniture.

- Roll Benders: Use three rollers in a pyramid arrangement to create large-radius arcs or circles from tube, pipe, or solid bar stock, commonly used for architectural rings and hoops.

- Mandrel Benders: Incorporate an internal support mandrel to prevent collapsing or excessive deformation of thin-walled tubing during tight-radius bending.

Key Components and Technological Advancements

Modern bending machines, especially press brakes, are sophisticated systems integrating mechanics and digital control:

- Frame & Ram: The robust C-frame or dual-side frame provides rigidity, while the ram delivers the downward force.

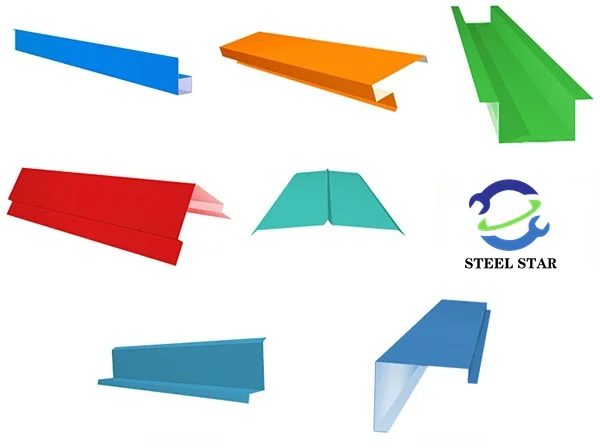

- Tooling (Punches & Dies): The heart of the operation. A vast array of standardized and custom tooling determines the bend angle, radius, and profile (e.g., V-dies, Gooseneck punches).

- Back Gauge: A programmable, CNC-controlled rear stop that positions the workpiece with extreme accuracy for consistent bend locations.

- Computer Numerical Control (CNC): The defining feature of modern machines. CNC systems automate the entire process: controlling ram position, back gauge movement, bend sequencing, and angle compensation. Operators program bend plans directly from CAD files.

- Advanced Features: Modern high-end machines may include angle measurement systems (like Cybelec or Delem CNC) that use sensors to measure the bend in real-time and automatically compensate for springback, automatic tool changers, and robotic part handling for fully automated cells.

Applications Across Industries

The applications are nearly limitless:

- Manufacturing: Chassis, brackets, enclosures, cabinets, and housings.

- Construction: Structural steel beams, cladding panels, ductwork, and roofing components.

- Transportation: Frame components, exhaust systems, and body panels.

- Energy: Conduit, support frames, and heat exchanger plates.

Choosing the Right Machine: A Matter of Precision and Scale

The selection depends on key factors:

- Material: Type, thickness (tonnage requirement), and tensile strength.

- Part Complexity: Number of bends, required tolerances, and bend radii.

- Production Volume: High-volume runs justify CNC and automation, while job shops may prioritize versatility.

From the brute force needed to shape thick steel plate to the delicate precision required for a complex aerospace bracket, the bending machine remains an indispensable pillar of fabrication. Its evolution from simple manual levers to intelligent, CNC-driven systems mirrors the advancement of modern manufacturing itself. By mastering the fundamental principle of deformation, it empowers creators and engineers to turn flat visions into durable, functional, and elegant three-dimensional realities, continuously shaping the world around us, one precise bend at a time.

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)