The Downspout Machine: Precision in Gutter Manufacturing

In the world of building construction and roofing, efficient water management is paramount. A critical component of this system is the humble downspout, or drainpipe, which channels rainwater from gutters safely away from a structure’s foundation. While seemingly simple, the mass production of these precisely formed metal channels relies on a sophisticated piece of industrial equipment: the Downspout Machine.

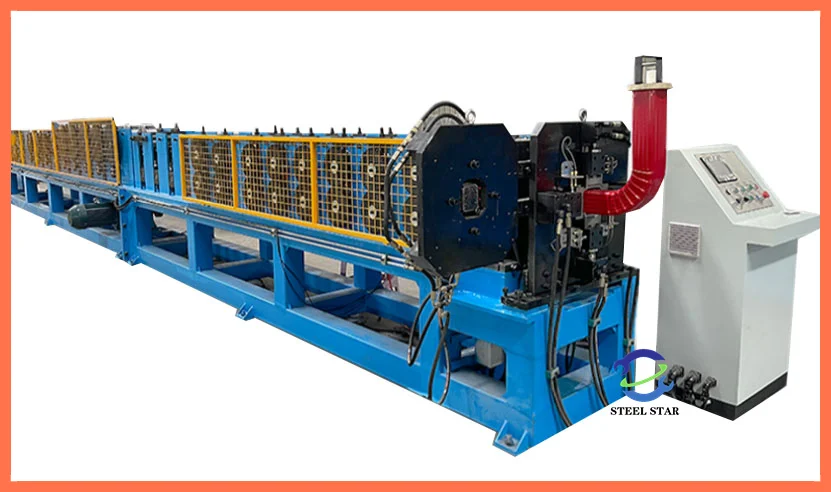

This machine is a specialized type of roll-forming system designed to transform flat coils of sheet metal (typically galvanized steel, aluminum, or copper) into continuous, perfectly formed downspouts in a single, automated operation. Its core function is to provide consistency, speed, and efficiency that manual fabrication could never achieve.

How It Works: The Forming Process

The operation of a downspout machine is a seamless sequence of engineering precision:

- Uncoiling & Straightening: The process begins with a large coil of sheet metal mounted on a decoiler. The metal is fed into a levelling unit that removes any curls or bends, ensuring a perfectly flat sheet enters the forming section.

- Pre-Punching (Optional): Before forming, some advanced machines include a punching station. This unit can precisely punch holes at set intervals for screw fasteners or create decorative outlet openings, all while the metal is still flat—a much simpler operation than punching a formed shape.

- The Heart: Progressive Roll Forming: The flat metal strip then passes through a series of contoured roller dies, arranged in consecutive stations. Each set of powered rollers incrementally bends the metal until it gradually takes the final cross-sectional shape of the downspout. Common profiles include rectangular, square, and round (also known as pipe). This gradual forming minimizes stress on the material and ensures a consistent, high-quality product.

- Cutting to Length: Once fully formed, the continuous downspout reaches a cutting mechanism. This is typically a flying cut-off saw or shear that moves synchronously with the moving downspout, making a clean, burr-free cut to pre-set lengths (commonly 10 or 20 feet) without stopping the production line.

- Output & Stacking: The finished downspout sections are then conveyed to a stacking table or rack, ready for bundling, packaging, and shipment.

Key Advantages and Features

- High Efficiency & Speed: Modern machines can produce downspouts at astonishing speeds, often exceeding 100 feet per minute, dramatically outpacing manual fabrication.

- Unmatched Consistency: Every piece produced is identical in dimensions and shape, ensuring perfect fit and a professional appearance during installation.

- Material Efficiency: The process generates minimal waste, especially when coupled with coil stock, optimizing material usage and reducing cost.

- Flexibility: Many machines are designed for quick tooling changes, allowing a single production line to switch between different downspout sizes or profiles with minimal downtime.

- Durability & Strength: The roll-forming process work-hardens the metal along the bends, creating a structurally rigid final product.

Applications and Impact

Downspout machines are the backbone of metal fabrication shops, roofing component manufacturers, and large-scale building material suppliers. They cater to both residential and commercial construction markets, producing standard components for new builds and replacement parts for renovations.

Their impact is significant: by automating production, these machines lower manufacturing costs, improve product availability, and contribute to the reliability of building drainage systems worldwide. They enable the economical use of corrosion-resistant, long-lasting materials, promoting sustainable construction.

Far from being a simple tool, the downspout machine is a testament to precision industrial automation. It transforms a raw material into a vital architectural component with remarkable efficiency. The next time you observe a neatly installed downspout protecting a building from water damage, it is worth considering the advanced machinery and engineering that made its perfect form and consistent quality possible. In the essential field of water management, the downspout machine plays a quietly indispensable role.

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)