In the architecture of any building, an effective rainwater management system is not merely an accessory but a fundamental component of structural integrity. At the heart of this system lies the rain gutter, a humble channel whose proper function prevents catastrophic water damage. While gutters themselves are ancient, their modern, efficient, and precise production is a feat of industrial engineering made possible by the Rain Gutter Machine. This specialized roll-forming equipment is the unsung hero of roofing supply chains, transforming raw metal into perfectly formed, consistent gutters at remarkable speeds.

From Coil to Gutter: The Core Process

A rain gutter machine is a complete production line designed for continuous operation. Its primary function is to take a flat coil of sheet metal—typically painted galvanized steel, aluminum, or copper—and form it into a seamless gutter profile, cut it to specified lengths, and prepare it for installation. The process is a symphony of coordinated stages:

- Loading and Decoiling: The process begins with a large coil of pre-finished metal mounted on a motorized decoiler. This coil acts as the raw material reservoir, allowing for uninterrupted production runs.

- Feeding and Straightening: The metal strip is fed into a precision leveling unit. This series of rollers carefully removes any coil memory or bends, ensuring the material entering the forming section is perfectly flat—a critical step for a flawless final product.

- Pre-Notching and Punching (Optional but Common): Before the forming begins, many advanced machines incorporate a punching station. Here, the flat metal strip can be notched for mitered corners, punched for outlet holes (where downspouts will attach), or embossed with decorative patterns. Performing these operations on a flat sheet is vastly simpler and more accurate than on a fully formed gutter.

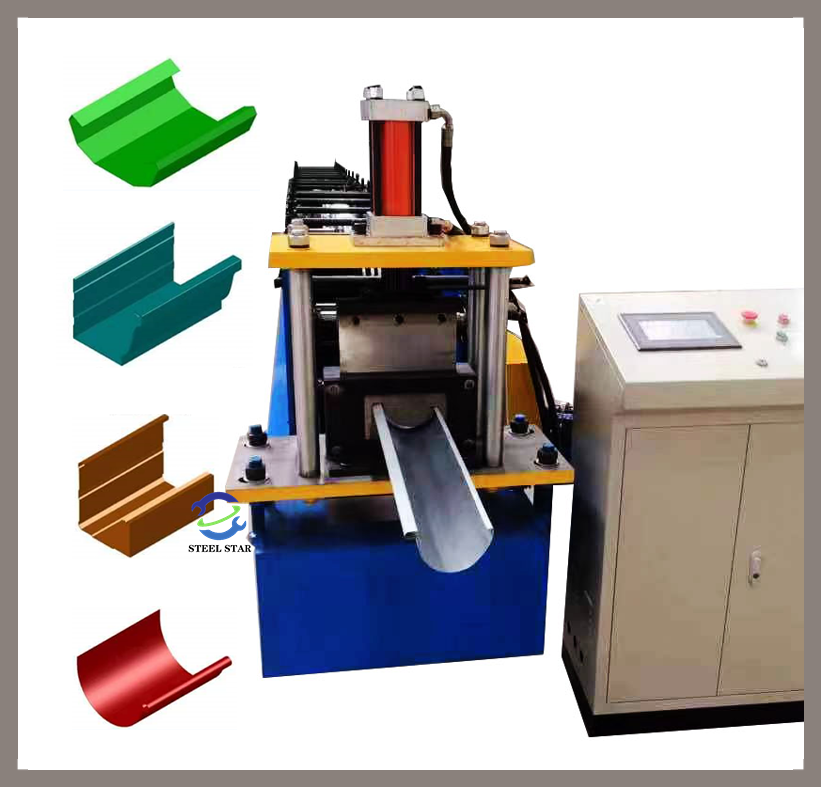

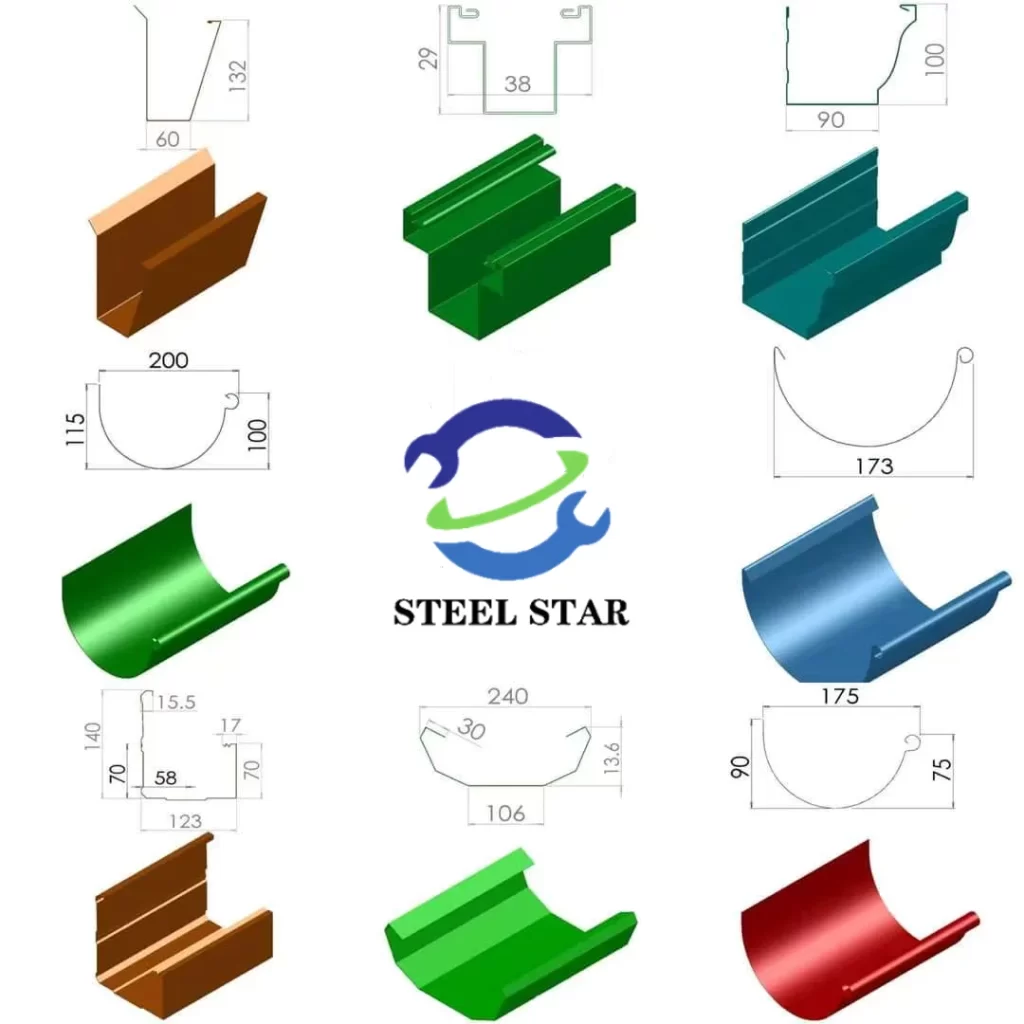

- The Heart: Progressive Roll Forming: The flat strip enters the forming mill, the core of the machine. It passes through a series of tandem roll stands, each equipped with a set of contoured, hardened steel rollers. Each successive stand makes an incremental bend in the metal. Gradually, over 10 to 20 stands, the recognizable “K-style” (ogee) or “half-round” gutter profile emerges. This gradual, cold-forming process work-hardens the metal at the bends, adding rigidity without heat.

- Cutting to Length: As the now fully formed, continuous gutter exits the final roll stand, it meets the cut-off mechanism. A “flying” hydraulic shear or saw moves synchronously with the moving gutter, making a clean, square cut to pre-programmed lengths (commonly 10, 20, or custom lengths) without stopping the production flow. This is controlled by a precision encoder measuring the exact length of material fed.

- Run-Out and Handling: The finished gutter section is conveyed gently onto a support table or an automatic stacker. For high-volume output, automated stacking arms bundle the gutters neatly, ready for strapping, protective packaging, and shipping.

Key Advantages of Machine-Formed Gutters

The adoption of dedicated gutter machines revolutionized the industry by offering:

- Unmatched Consistency and Quality: Every foot of gutter produced has identical dimensions, shape, and finish. This ensures seamless fit during installation, a professional aesthetic, and reliable performance.

- High Production Speed and Efficiency: Modern machines can produce gutter at speeds exceeding 100 feet per minute, enabling manufacturers to meet large-scale demand for both residential and commercial projects efficiently.

- Material and Labor Efficiency: The automated process minimizes waste from miscuts or errors. One operator can manage an entire production line, significantly reducing labor costs per unit compared to manual fabrication.

- Versatility and Flexibility: Many machines are designed for quick tooling changes, allowing a single production line to switch between different gutter styles (K-style to half-round), sizes (5-inch, 6-inch), or even materials with minimal downtime.

- On-Demand Seamless Lengths: By producing gutters from a continuous coil, machines can create “seamless” sections up to the length a truck can transport (often 40-50 feet). This reduces the number of end joints in a run, which are potential leak points.

Types and Applications

Gutter machines vary in scale and output:

- Portable / On-Site Machines: These are lighter, trailer-mounted units used by contractors to produce seamless gutters directly at a job site. They eliminate transportation damage and allow for perfect custom lengths.

- Stationary Industrial Lines: Found in manufacturing plants, these are heavy-duty, high-speed systems designed for volume production to supply building material distributors and large roofing contractors.

The Broader Impact

Beyond mere production, the rain gutter machine has shaped the construction industry. It has made durable, long-lasting metal gutter systems cost-competitive with less reliable alternatives. By enabling the efficient use of corrosion-resistant, recyclable materials like aluminum, it contributes to more sustainable building practices. Furthermore, the reliability of machine-made components supports the growth of the roofing and siding contractor industry by providing a dependable, standardized product.

The rain gutter machine is a paradigm of focused industrial automation. It takes a fundamental building need and fulfills it with precision, speed, and remarkable efficiency. Its product, the manufactured gutter, is a critical first line of defense in protecting property from water intrusion. From a massive coil of metal to the precise channel safeguarding a home, the journey is orchestrated by this robust and ingenious machine. In the landscape of construction technology, the rain gutter machine stands as a testament to how specialized engineering continuously improves even the most traditional building components, ensuring they meet the demands of the modern world.

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)