Coil Slitting Equipment: The Precision Engine of Modern Metal Processing

In the vast landscape of industrial manufacturing, where efficiency and precision are paramount, coil slitting equipment operates as a critical, yet often unsung, workhorse. This machinery is the definitive solution for transforming wide master coils of metal—the raw material backbone of countless industries—into narrow, tightly wound strips of precise width, ready for the next stage of production. From automotive components and appliance casings to construction materials and electronics, the journey of most flat-rolled metal products begins at a slitting line.

What is Coil Slitting?

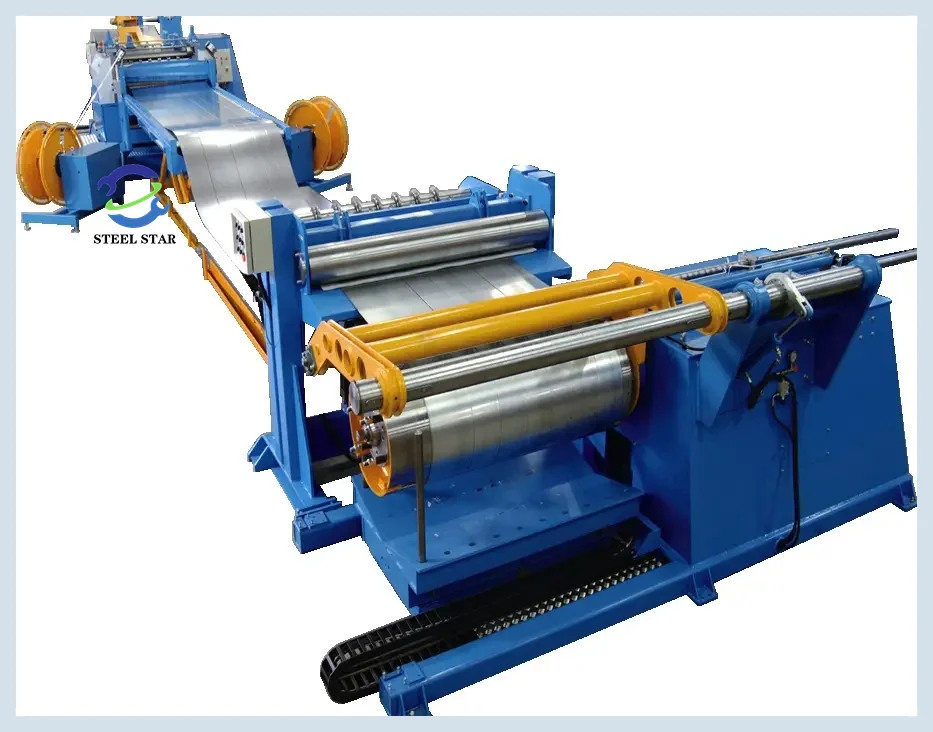

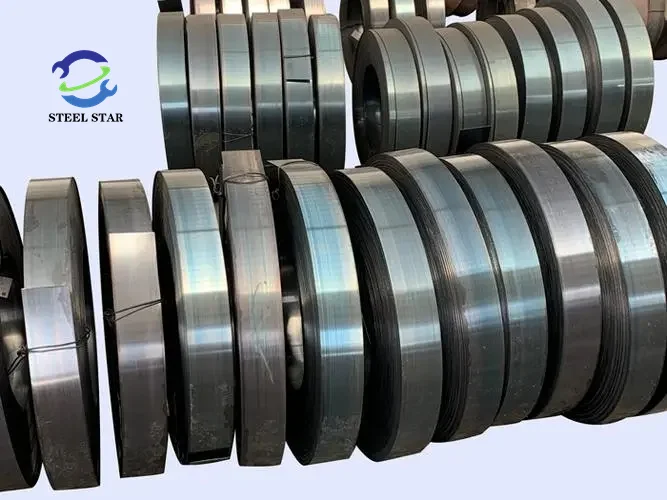

Coil slitting, also known as strip slitting, is a shearing process. A wide master coil, typically of steel, aluminum, stainless steel, or other metals, is fed through a machine where multiple pairs of rotary circular knives (or slitter knives) make longitudinal cuts. The process converts the single wide coil into a number of narrower strips with parallel edges, which are then separately rewound into individual, manageable coils. It is a continuous, high-volume process designed for maximum yield and minimal material waste.

Core Components and Function

A modern coil slitting line is an integrated system of synchronized components:

- Pay-off Reel/Decoiler: This heavy-duty unit securely holds and unwinds the master coil, feeding it into the line under controlled tension.

- Entry Loop Pit or Bridle: Creates a buffer of material to ensure continuous, non-stop feeding into the slitter head, even during the acceleration and deceleration of the rewind ends.

- The Slitter Head: The heart of the machine. It houses the arbor (a massive shaft) onto which the male slitter knives (top) and female spacers or duplex knives (bottom) are mounted in a precise configuration that determines the number and width of the output strips. The clearance and overlap between the upper and lower knives are meticulously set for a clean shear.

- Strip Separator/Lifter: After slitting, the newly separated strips must be guided apart to prevent interlocking and scratching. This is done using tension bars, paper separators, or air blowers.

- Recoiler/Tension Stand: This is where the individual strips are rewound onto separate mandrels. Precise tension control is vital here to produce tightly wound, firm, and defect-free daughter coils. Systems can include twin dual rewind heads for non-stop operation or a single mandrel for simpler applications.

- Scrap Winders: Efficiently collect the thin edge trim from both sides of the master coil, a necessary by-product of the slitting process.

- PLC Control System: The brain of the operation. Modern slitters are governed by sophisticated Programmable Logic Controllers (PLCs) that manage speed, tension, knife positioning, and diagnostic functions, ensuring repeatability and minimal setup time.

Key Types of Slitting Processes

- Loop Slitting: The most common method for high-speed, high-volume production. The material forms a loop between the slitter head and the recoiler, allowing the rewinding process to continue uninterrupted while a finished coil is discharged and a new mandrel is prepared.

- Pull-Through Slitting: A simpler, often offline process where the material is pulled straight through the slitter and rewound. Suited for lower volumes, thicker materials, or specialty metals.

- Scrap-Free Slitting: An advanced configuration using specialized tooling to minimize or completely eliminate side trim, pushing material yield to its theoretical maximum.

The Critical Advantages

- Unmatched Efficiency: Slitting lines process tons of material per hour, providing a continuous supply of precisely sized strips to downstream stamping, roll forming, or fabricating operations.

- Superior Edge Quality: Properly set rotary knives produce a clean, burr-minimized cut edge, which is crucial for subsequent forming processes and final product quality.

- Material Yield Optimization: By slitting multiple strips from one master coil, manufacturers can customize widths to exact order requirements, dramatically reducing scrap compared to other cutting methods.

- Enhanced Material Properties: The process maintains the temper and mechanical properties of the metal, unlike thermal cutting methods which can create heat-affected zones.

- Operational Flexibility: Quick-change knife arbors and programmable setups allow a single line to handle a wide range of materials, thicknesses, and widths, making it responsive to diverse customer demands.

Applications Across Industries

The output of coil slitting equipment feeds directly into the manufacturing pulse of the modern world:

- Automotive: Body panels, chassis components, trim.

- Appliances: Housings for refrigerators, washing machines, ovens.

- Construction: Roofing, wall cladding, steel studs, and framing.

- Electronics: Enclosures, heat sinks, shielding.

- Aerospace: Precise narrow strips for specialized components.

Coil slitting equipment is a masterpiece of industrial engineering that combines brute force with microscopic precision. It is not merely a cutter of metal but a fundamental value-adding process that bridges raw material production and finished product fabrication. By delivering consistent, high-quality slit coils with exceptional efficiency, it forms an indispensable link in the global supply chain, quietly enabling the production of the metal goods that shape our everyday lives. As demands for tighter tolerances, smarter automation, and higher yields grow, the evolution of slitting technology continues to be a key driver of manufacturing competitiveness.

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)