The Fundamental Principle: Controlled Division

At its core, a coil slitting machine performs a seemingly simple task: dividing a wide metal coil (often 600mm to 2000mm wide) into several narrower strips (from 10mm to 600mm each) with minimal material loss and maximum edge quality. However, achieving this with industrial precision at high speeds involves a complex interplay of mechanical engineering, material science, and advanced control systems. The process, known as “slitting,” utilizes pairs of rotary circular knives mounted on arbors to make longitudinal cuts as the metal passes through at controlled tension and speed.

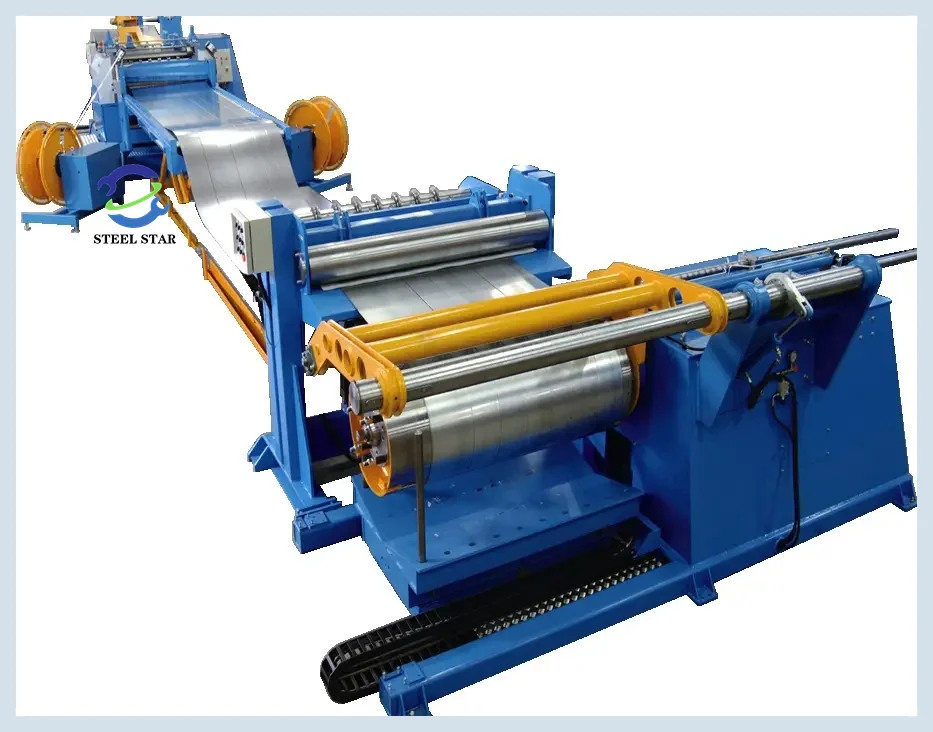

Anatomy of a Modern Slitting Line: Key Components and Their Functions

A complete coil slitting line represents an integrated system of specialized stations working in concert. Understanding each component reveals the sophistication behind this fundamental process.

1. Decoiling and Feeding System

The process begins with the payoff reel or decoiler, which securely holds and unwinds the master coil. Modern lines employ motorized decoilers with tension control systems to ensure smooth, consistent feeding. Coil cars or hydraulic lift tables facilitate the loading of heavy coils (often weighing 10-30 tons) onto the mandrel, while edge guides and centering devices align the material perfectly with the slitting head. The initial peeler separates and straightens the leading edge of the coil for proper threading.

2. The Entry Section: Preparation and Alignment

Before slitting, the material must be perfectly prepared:

- Peeling and Threading Table: Mechanically assists in feeding the leading edge into the line.

- Pinch Roll Assembly: A set of powered rolls that grip the material and positively feed it into the slitter at controlled speed.

- Loop Pit or Dancer System: Creates a material buffer (loop) between the decoiler and slitter head to isolate tension variations, ensuring consistent feeding into the cutting section. Modern lines may use electronic loopers with servo-controlled trolleys.

- Edge Trimming Shear (Optional): Removes irregular or damaged edges from the master coil before slitting, improving edge quality and preventing knife damage.

3. The Heart of the Machine: The Slitter Head

This is where precision cutting occurs. The slitter head consists of:

- Top and Bottom Arbors (Shafts): Hardened, precision-ground steel shafts that hold the cutting knives. The top arbor is typically adjustable for different strip widths.

- Circular Slitting Knives: Made from high-grade tool steel (like D2 or M2) or tungsten carbide for abrasive materials. Knives are precisely ground with specific geometries (clearance angles, bevels) optimized for material type and thickness.

- Spacers and Shims: Precision-machined rings placed between knives on the arbors to set the exact strip width. Modern systems may use computerized width setting for rapid changeovers.

- Knife Holders and Quick-Change Systems: Allow for efficient knife mounting and removal, minimizing downtime during width changes.

- Side Trimmers: Optional rotary cutters that clean up the outer edges of the slit material.

4. The Separator: Preventing Strip Contact

Immediately after cutting, the newly slit strips tend to curl and could overlap or scratch each other. Various separation methods are employed:

- Staggered Slitting: Offsetting top and bottom knives slightly causes strips to naturally diverge.

- Strip Separator Plates or Fingers: Thin, hardened steel plates positioned between strips to keep them apart.

- Air Separator Nozzles: Use precisely directed compressed air to lift and separate strips.

- Magnetic Separators: For ferrous materials, use magnetic fields to control strip position.

5. The Tension and Recoiling System

After separation, each slit strip must be independently rewound into a tight, neat coil:

- Drag Brakes or Tensioners: Apply controlled back-tension to each strip during rewinding to ensure tight, stable coils.

- Recoiler Mandrel: The core shaft on which slit strips are rewound. May be:

- Single Mandrel: All strips are rewound onto one mandrel, then separated later.

- Dual Drum Recoiler: Uses two rotating drums around which strips are wound, allowing for continuous operation (one drum winds while the other is unloaded).

- Multi-Spindle Recoiler: Each strip winds onto its own individual mandrel for maximum control and quality.

- Edge Guides (EPC Systems): Electro-pneumatic or hydraulic guides ensure each strip winds in perfect alignment, producing straight-edged coils.

- Tension Control Systems: Sophisticated electronic systems (using load cells, dancer arms, or torque control) maintain precise tension throughout the rewinding process.

6. Auxiliary Systems

- Scrap Winders: Collect edge trim and defective material for recycling.

- Lubrication/Coolant Systems: For coated materials or high-speed operations, apply lubricant to knives and material to reduce heat, extend tool life, and improve cut quality.

- Deflector Rollers and Guides: Direct material flow through the line.

- Safety Enclosures and Noise Reduction Housing: Protect operators and reduce workplace noise.

Types of Slitting Machines and Their Applications

Coil slitters are engineered for specific materials, thicknesses, and production requirements:

1. By Material and Thickness

- Light-Gauge Slitters: Handle thin materials (0.1mm to 2.0mm) like aluminum foil, tinplate, or thin-gauge steel for packaging, electronics, and consumer goods. Emphasize precision, tension control, and surface protection.

- Medium/Heavy-Gauge Slitters: Process thicker materials (1.0mm to 12mm or more) for structural steel, plate, and heavy-duty applications. Focus on power, knife strength, and handling heavy coils.

2. By Knife Configuration

- Pull-Through Slitters: The simplest design where the recoiler pulls material through stationary knives. Suitable for lighter materials and lower volumes.

- Loop Slitters: Incorporate a tension-isolating loop pit between decoiler and slitter head. The industry standard for most applications, offering better control and quality.

- Double-Loop Slitters: Include a second loop after the slitter head before the recoiler, providing maximum tension isolation for sensitive or precision materials.

3. By Recoiling Method

- Single-Reel Slitters: All strips wound together, then separated manually.

- Dual-Drum Recoilers: Enable continuous operation for high-volume production.

- Multi-Spindle Recoilers: Provide individual tension control for each strip, ideal for mixed-width orders or sensitive materials.

Technical Specifications and Performance Parameters

Modern high-performance slitting lines exhibit impressive capabilities:

- Material Width: Up to 2000mm incoming, down to 6mm slit width

- Material Thickness: 0.05mm to 16mm (depending on line type)

- Line Speed: 30 to 1000 meters per minute (varies by material)

- Tolerance Accuracy: ±0.05mm to ±0.5mm on slit width

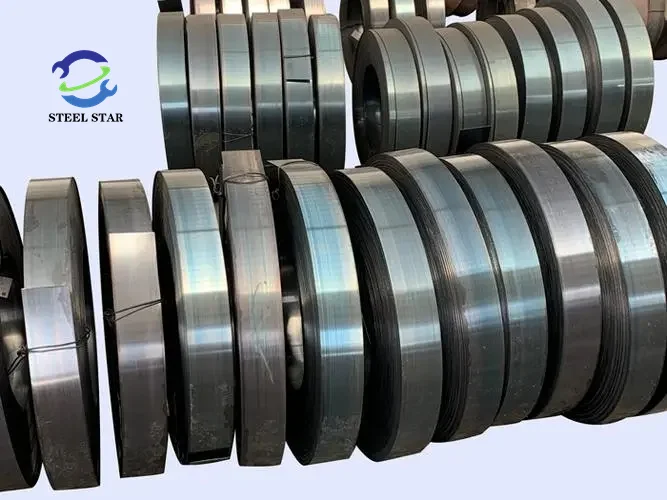

- Coil Weight: Up to 40,000 kg incoming, 500-10,000 kg slit coils

- Knife Life: 100 to 2000 kilometers of cut between sharpenings (depending on material)

- Changeover Time: As little as 15 minutes with quick-change systems

The Slitting Process: A Step-by-Step Overview

- Planning and Setup: Operators program the line based on order specifications—strip widths, tolerances, coil weights. Knives are selected, spaced, and mounted on arbors with precision spacers.

- Loading and Threading: The master coil is loaded onto the decoiler, centered, and the leading edge is mechanically fed through the entry section, slitter head, and separators to the recoiler.

- Test Run and Adjustment: A short section is run at low speed to verify strip widths, edge quality, and tension. Micro-adjustments are made to knife positions or line parameters.

- Production Run: The line operates at programmed speed, with automated systems monitoring tension, width, and quality. Operators monitor for issues like burr formation, edge curl, or surface scratches.

- Recoiling and Unloading: When the master coil is fully processed, the slit coils are unloaded from the recoiler, banded, labeled, and prepared for shipment or storage.

Key Considerations for Optimal Slitting Performance

1. Knife Selection and Maintenance

- Geometry: Clearance angles, bevel designs, and hardness must match the material being slit.

- Sharpening: Regular precise regrinding maintains cutting quality and prevents material deformation.

- Setup: Proper knife overlap (typically 20-40% of material thickness) and side clearance are critical for clean cuts.

2. Tension Control

Proper tension—neither too loose nor too tight—is essential for:

- Preventing telescoping (uneven winding)

- Minimizing edge wave or curl

- Ensuring consistent coil density

- Avoiding surface damage

3. Material Characteristics

Different materials present unique challenges:

- Coated Materials (Galvanized, Painted): Require careful handling to prevent coating damage

- High-Strength Steels: Generate more cutting force and require robust equipment

- Stainless Steels: Work-harden during cutting, demanding sharp knives and proper setup

- Non-Ferrous Metals (Aluminum, Copper): Softer but more prone to edge burrs and surface marking

Technological Advancements in Modern Slitting

Today’s slitting lines incorporate numerous technological improvements:

Automation and Control Systems

- Computerized Set-Up: Automated width setting systems position knives with precision, reducing changeover time from hours to minutes.

- Integrated Quality Monitoring: Laser measurement systems continuously check strip width, while vision systems inspect edge quality.

- Predictive Maintenance: Vibration analysis and temperature monitoring predict bearing failure or knife wear before quality is affected.

- Data Integration: Full production data logging for traceability and process optimization.

Advanced Mechanical Features

- Quick-Change Knife Systems: Hydraulic or pneumatic systems for rapid knife changes.

- Servo-Driven Components: For precise control of loops, guides, and tension.

- Hydrostatic Bearings: In high-speed lines to reduce friction and vibration.

- Noise Reduction Enclosures: Meeting stricter workplace safety standards.

Economic and Operational Benefits

Implementing modern coil slitting technology delivers substantial advantages:

Material Efficiency

- Reduced Scrap: Precision slitting minimizes edge trim and defective material.

- Optimal Utilization: Allows customers to purchase exact widths needed, reducing waste.

- Improved Yield: Advanced systems can achieve over 99% material utilization.

Production Efficiency

- High Throughput: Modern lines can process over 100 tons per hour.

- Rapid Changeovers: Quick-adjust systems minimize downtime between orders.

- Labor Optimization: Automated lines require fewer operators with reduced physical strain.

Quality Enhancement

- Superior Edge Quality: Burr-free edges reduce downstream processing issues.

- Consistent Dimensions: Precise width control ensures compatibility with customer equipment.

- Surface Protection: Careful handling preserves coatings and finishes.

Industry Applications and Market Significance

Coil slitting serves virtually every metal-consuming industry:

1. Automotive Industry

- Body Panels: Slit coils for stamping hoods, doors, and fenders

- Structural Components: High-strength steel for chassis and safety components

- Trim and Molding: Decorative and functional trim pieces

2. Construction and Building Products

- Roofing and Siding: Coated steel and aluminum for architectural panels

- Structural Framing: Studs, tracks, and purlins for buildings

- HVAC Ductwork: Galvanized steel for air handling systems

3. Appliances and Consumer Goods

- Appliance Housings: Refrigerators, washers, and ovens

- Packaging Materials: Cans, containers, and closures

- Furniture and Fixtures: Office furniture, display systems, shelving

4. Electrical and Electronics

- Motor Laminations: Precision electrical steel for motors and transformers

- Shielding and Enclosures: EMI/RFI shielding and component enclosures

- Connectors and Contacts: Copper and brass alloys for electrical components

Safety Considerations and Best Practices

Operating coil slitting equipment involves significant hazards that must be rigorously managed:

Primary Safety Systems

- Light Curtains and Safety Mats: Prevent access to dangerous areas during operation

- Two-Hand Controls: Require simultaneous activation for hazardous functions

- Emergency Stop Systems: Strategically placed stops with lock-out/tag-out capability

- Knife Handling Protocols: Specialized procedures and tools for safe knife changes

Operational Safety Practices

- Comprehensive Training: Operators must understand both equipment operation and material handling

- Regular Maintenance: Preventive maintenance prevents unexpected failures

- Proper Material Handling: Coils can weigh tens of tons and require appropriate equipment and techniques

- Noise and Dust Control: Hearing protection and ventilation systems protect worker health

Environmental Considerations and Sustainability

Modern slitting operations increasingly prioritize environmental responsibility:

- Scrap Recycling: Virtually 100% of slitting scrap is recycled back into production

- Energy Efficiency: Variable frequency drives and regenerative braking reduce power consumption

- Lubricant Management: Advanced filtration extends coolant life and minimizes waste

- Noise Reduction: Enclosures and dampening materials protect community environments

Future Trends and Developments

The coil slitting industry continues to evolve with several emerging trends:

Industry 4.0 Integration

- Digital Twins: Virtual models of slitting lines for optimization and training

- IoT Connectivity: Real-time monitoring of equipment performance from anywhere

- AI-Powered Optimization: Machine learning algorithms that optimize speed, tension, and knife setup for different materials

- Blockchain Traceability: Complete material history from mill to finished product

Advanced Materials Processing

- Ultra-High-Strength Steels: Equipment capable of handling 1500MPa+ materials

- Composite Materials: Adapting slitting technology for new material combinations

- Thinner Gauges and Tighter Tolerances: Meeting demands of miniaturized electronics and precision components

Enhanced Automation

- Robotic Material Handling: Fully automated coil loading, transfer, and packaging

- Autonomous Quality Inspection: Computer vision systems that identify defects invisible to human operators

- Predictive Process Control: Systems that anticipate and correct issues before they affect quality

The coil slitting machine exemplifies how a fundamental industrial process has evolved through continuous innovation. From its mechanical beginnings to today’s computer-controlled precision systems, slitting technology has kept pace with manufacturing’s ever-increasing demands for efficiency, quality, and flexibility.

As the critical bridge between bulk material production and finished product fabrication, the slitting line determines not only the economic efficiency of countless manufacturing processes but also the quality and performance of end products across industries. Its ability to transform massive coils into precisely dimensioned strips with minimal waste represents a triumph of engineering that directly contributes to manufacturing competitiveness and sustainability.

The future of coil slitting lies in even greater integration—seamlessly connecting with both upstream material production and downstream fabrication through data-driven systems that optimize the entire value chain. As materials become more advanced and tolerances more exacting, the slitting machine will continue to evolve, maintaining its essential role as the precision foundation upon which modern metal fabrication is built.

In an era of increasingly sophisticated manufacturing, the coil slitting machine remains a testament to the enduring importance of doing fundamental things exceptionally well—transforming raw material into precisely engineered feedstock with efficiency, consistency, and remarkable precision.

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)