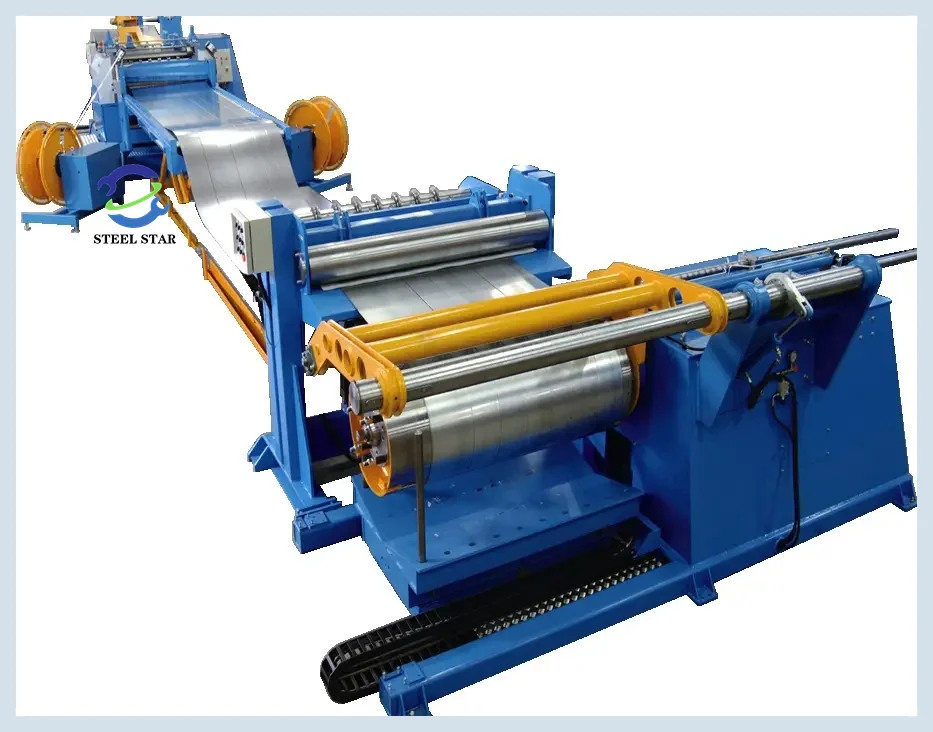

Coil Slitting Machine Line: The Precision Engine of Metal Processing

A coil slitting machine line is a fundamental and critical system in modern metal processing, serving as the primary method for transforming wide master coils into multiple narrower strips of precise width. This process, essential for feeding downstream production like stamping, roll forming, and tube mills, exemplifies efficiency and precision in industrial manufacturing.

Core Function and Process

The primary function of a slitting line is to longitudinally cut a wide metal coil (from 600mm to over 2000mm wide) into a specified number of narrower strips (from 10mm to 600mm or more) with minimal material loss and edge deformation. The process maintains the original coil’s thickness while creating multiple daughter coils ready for further fabrication.

Key Components of an Integrated Slitting Line

A complete, automated line consists of several synchronized stations:

- Pay-off Reel / Decoiler: Holds and feeds the master coil into the line. Heavy-duty units may include hydraulic expansion mandrels and automatic coil loading arms.

- Peeler and Flattener: A peeler head separates the leading edge of the coil, which is then fed through a multi-roll leveler to remove coil set and crossbow, ensuring flat material enters the slitter.

- Slitter Head: The heart of the machine. It houses:

- Upper & Lower Arbors: Precision-ground shafts that hold the slitting tools.

- Slitter Knives: Hardened, wear-resistant circular knives. The top knives (driven) and bottom knives (idler) are set to the required strip widths using spacers.

- Tooling Setup: Accuracy here is paramount for strip width tolerance and edge quality. Different knife designs (crush cut, razor cut, shear cut) are used for varying material types and thicknesses.

- Scrap Winders (or Chopper): Separates and recoils the thin edge trim, a necessary by-product of the slitting process, for recycling.

- Separator Assembly (Drag System): Prevents slit strips from tangling as they exit the slitter head, typically using a series of plates or rolls to maintain separation.

- Tension Stand / Bridle: Creates and maintains critical back tension on the strip during slitting and recoiling, ensuring tight, stable daughter coils.

- Recoilers (One or Multiple): Wind the finished narrow strips into individual coils. High-speed lines often feature dual dual-shaft recoilers for continuous operation—one set winds while the other is unloaded.

- PLC Control System: Integrates all drives, hydraulics, and pneumatics. It manages line speed, tension, and often includes a coil data management system for tracking production.

Types and Cutting Methods

- Loop-Type Slitting: The strip forms a loop between the slitter head and recoiler, allowing for precise tension control and higher speeds, ideal for thin to medium-gauge material.

- Pull-Through Slitting: A simpler configuration where the recoiler pulls the material directly through the slitter. Often used for heavier gauge materials.

- Cutting Methods: The choice depends on material:

- Shear Cutting: Most common. Uses opposed knives for clean, square edges on a wide range of metals.

- Crush Cutting: Uses a sharp top knife against a hardened, unsharpened bottom roll. Suitable for softer, non-ferrous metals.

- Razor/Score Cutting: Uses a sharp circular blade to score and then fracture the material, used for very thin foils.

Advantages and Industry Impact

- Massive Throughput and Efficiency: Processes entire master coils in a single, continuous run, dramatically outperforming single-strip cutting methods.

- Precision and Consistency: Delivers narrow strips with exceptionally tight width tolerances (±0.1mm or better) and clean, burr-minimized edges, which is crucial for high-speed downstream forming.

- Material and Labor Optimization: Maximizes yield from master coils and operates with minimal manual intervention, reducing overall production costs.

- Flexibility: Quick knife and spacer changes allow the same line to process different strip widths and materials (steel, aluminum, stainless steel, copper), making it highly adaptable to job-shop and just-in-time manufacturing.

Technological Integration

Modern lines feature:

- Servo-Driven Width Adjustment: For automatic, precise knife positioning from the HMI, reducing setup time.

- Automatic Strip Guiding (CPC/EPC): Ensures the master coil is centered, and slit strips are correctly guided onto their respective recoiler mandrels.

- In-line Edge Conditioning: Optional units to deburr or round edges immediately after slitting.

- Advanced Data Management: Tracks coil genealogy, production parameters, and maintenance schedules for total process control.

The coil slitting line is an indispensable workhorse in the metal supply chain. It is the critical first step in value-added processing, enabling the efficient and precise creation of feedstock for countless manufactured goods, from automotive parts and appliances to building materials and electronics. By combining robust mechanical design with sophisticated control technology, the modern slitting line ensures that the fundamental building blocks of industry—metal strip—are produced with the quality, consistency, and efficiency demanded by global manufacturing.

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)