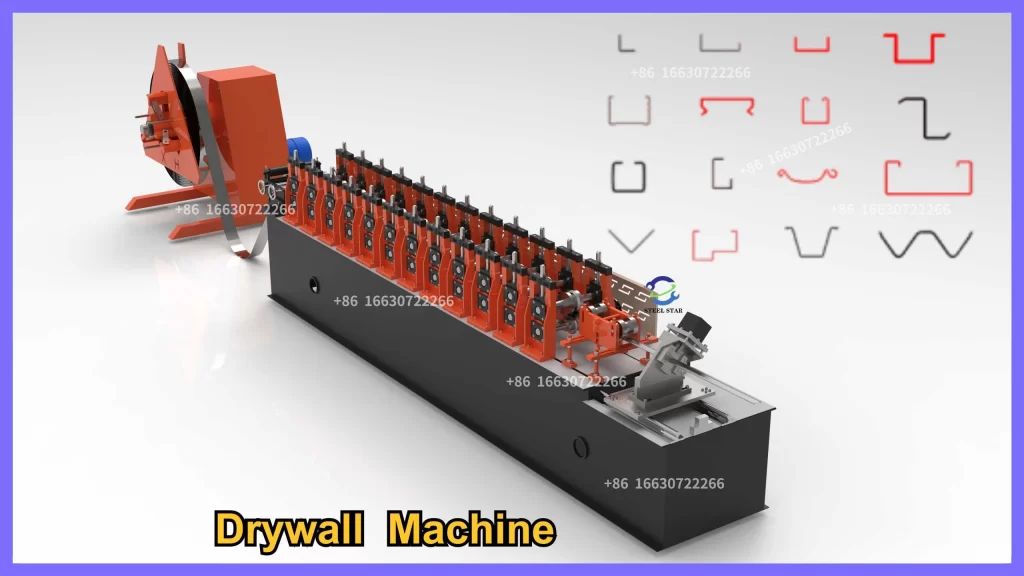

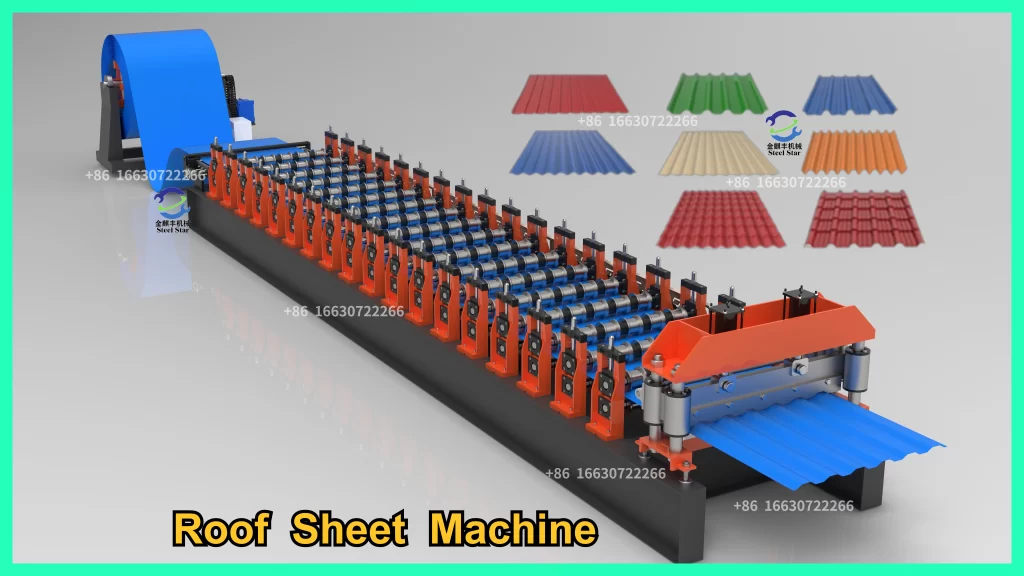

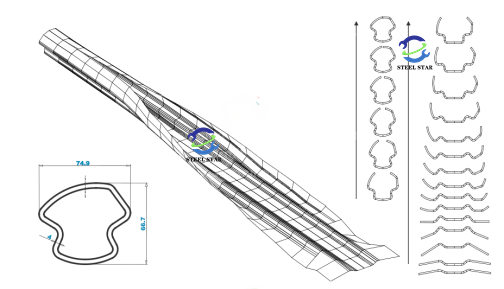

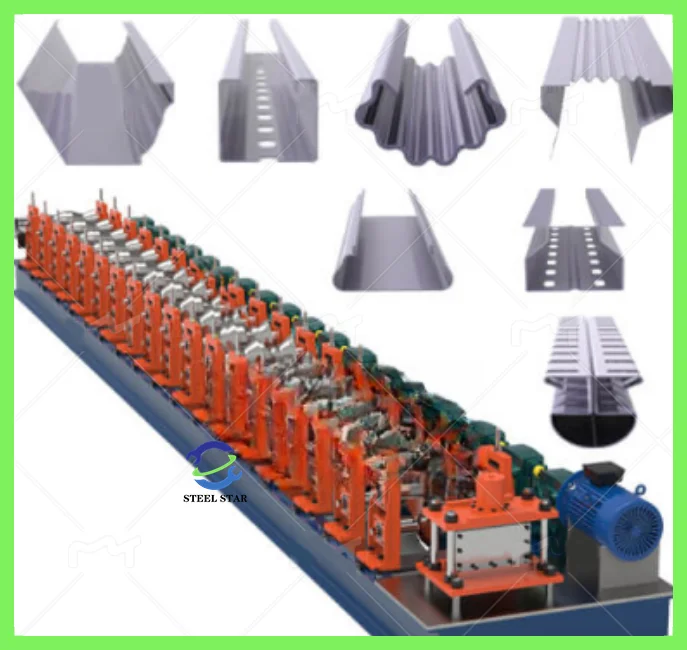

Roll forming is a type of rolling that involves continuously bending long strips of metal sheet (typically coiled steel) into the desired cross-section.Design the mold shape and number of groups according to the required size. The shrinkage ratio of each group of cold bending is different. Through cold bending group by group, the final desired size can be achieved. Combined with electronic control system, hydraulic system, shearing system and counting encoder to realize automated operation.

Roll forming is a type of rolling that involves continuously bending long strips of metal sheet (typically coiled steel) into the desired cross-section.

Design the mold shape and number of groups according to the required size. The shrinkage ratio of each group of cold bending is different. Through cold bending group by group, the final desired size can be achieved. Combined with electronic control system, hydraulic system, shearing system and counting encoder to realize automated operation.

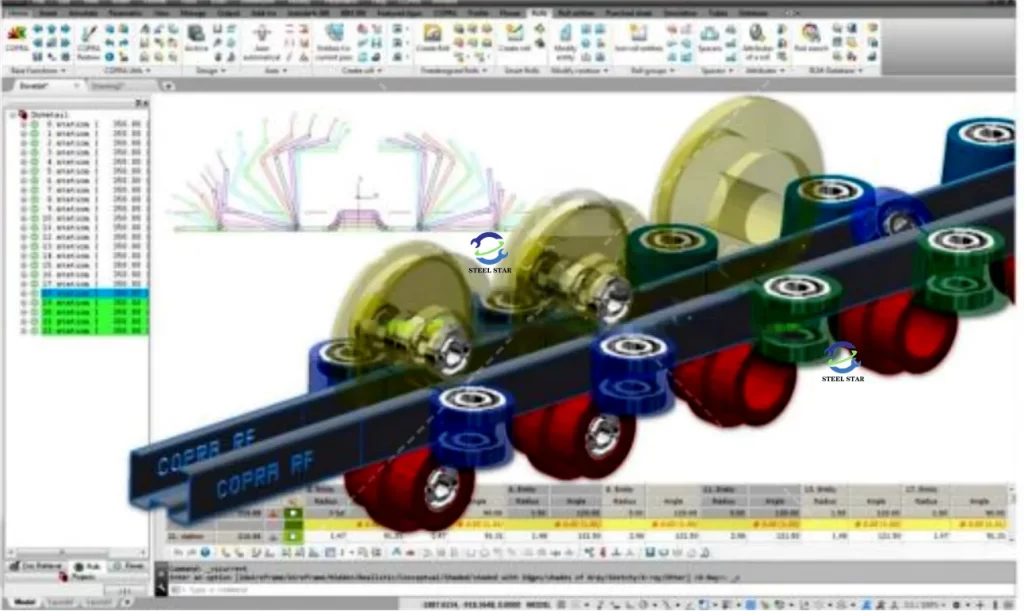

Virtual roll forming production line

Based on finite element simulation, the software can solve problems such as high costs and quality defects in product development. Through integration with other COPRA software, the design can be optimized and errors can be corrected quickly and directly in COPRA RF design software based on simulation analysis results. If necessary, the stick flower design can also be automatically adjusted. On the other hand, the simulation results of roll forming can also help engineers better understand the deep-seated problems of roll forming (Know-How).

In the forming process of profiles and tubes, material changes often bring a series of problems, but such problems will not occur in COPRA finite element analysis. For common defects such as wrinkles, twists or bends on the edges of metal sheets, these problems can be avoided through simulation analysis verification.

Roll forming machines are widely used in buildings, factories, temporary buildings, shelves, photovoltaic brackets, etc. to produce roof tiles, wall tiles, floor tiles and other types of building materials of different materials. It can be used not only for roofs of residential buildings, commercial buildings and industrial buildings, but also for agricultural buildings and landscape projects.

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)