The Versatile World of Corrugated Metal

Abstract: Corrugated metal, with its unique ridged structure, has found extensive applications across various industries. This article explores the properties, manufacturing processes, historical development, and diverse uses of corrugated metal, highlighting its significance and impact in modern society. It also delves into considerations for its installation, maintenance, and future trends, providing a comprehensive overview of this remarkable material.

Manufacturing Processes

The production of corrugated metal typically involves several key steps.

3.1 Sheet Metal Preparation

The starting point is a flat sheet of metal, which can be made from steel, aluminum, or other suitable alloys. The metal sheet is carefully inspected and prepared to ensure its quality and surface integrity. Any imperfections or contaminants are removed, and the sheet is cut to the desired size and shape.

3.2 Corrugation Formation

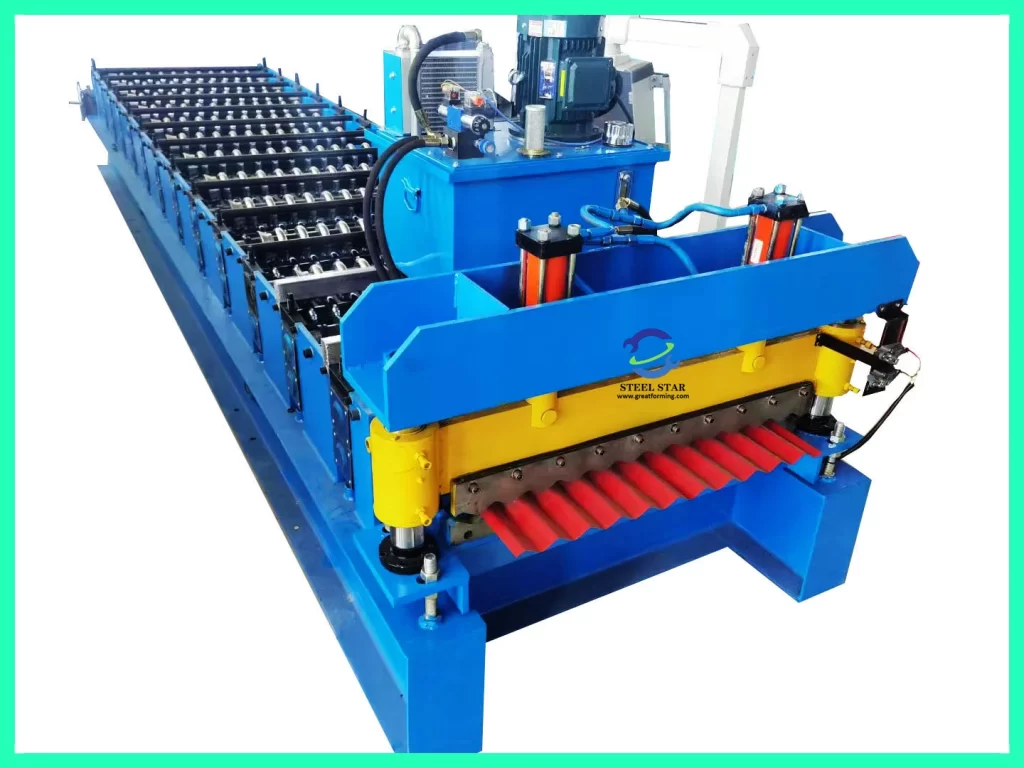

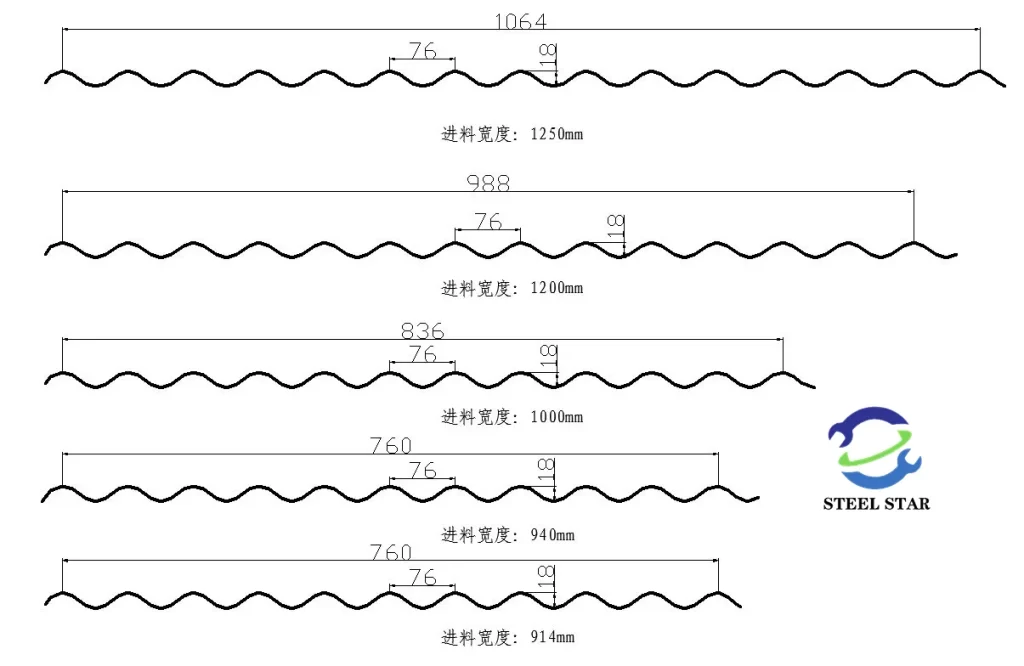

The corrugation process is the core of manufacturing corrugated metal. There are different methods for creating the ridges, but one common approach is through a roll-forming machine. The flat metal sheet is passed through a series of rollers that gradually shape it into the corrugated pattern. The rollers are precisely engineered to produce the specific corrugation profile, which can vary in terms of the height, width, and pitch of the ridges. The roll-forming process is highly efficient and can produce corrugated metal sheets in large quantities with consistent quality.

3.3 Finishing Treatments

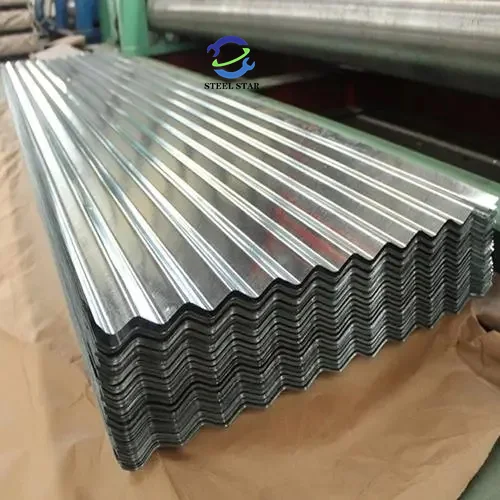

After the corrugation is formed, the metal may undergo additional finishing treatments. For galvanized steel, the zinc coating is applied either through a hot-dip galvanizing process, where the metal is immersed in molten zinc, or an electro-galvanizing process, which uses an electrochemical reaction to deposit a thin layer of zinc. Aluminum corrugated metal may be anodized to improve its surface hardness and corrosion resistance. Additionally, the metal can be painted or coated with other protective and decorative finishes to meet specific design requirements or enhance its durability in certain applications.

Corrugated metal is a remarkable material with a wide range of properties and applications. Its strength, durability, lightweight nature, and aesthetic appeal have made it a popular choice in construction, agriculture, transportation, and interior design. Through continuous innovation in manufacturing processes and the exploration of new applications and trends, corrugated metal is set to maintain its significance and relevance in the modern world. Whether it is providing shelter for a building, storing agricultural produce, or adding a unique design element to an interior space, corrugated metal continues to prove its worth as a versatile and reliable material. Understanding its properties, manufacturing, history, applications, installation, maintenance, and future trends is essential for architects, engineers, designers, and anyone involved in the fields where this material is utilized.

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)