Corrugated Profile Machines: The Workhorses of Metal Forming Technology

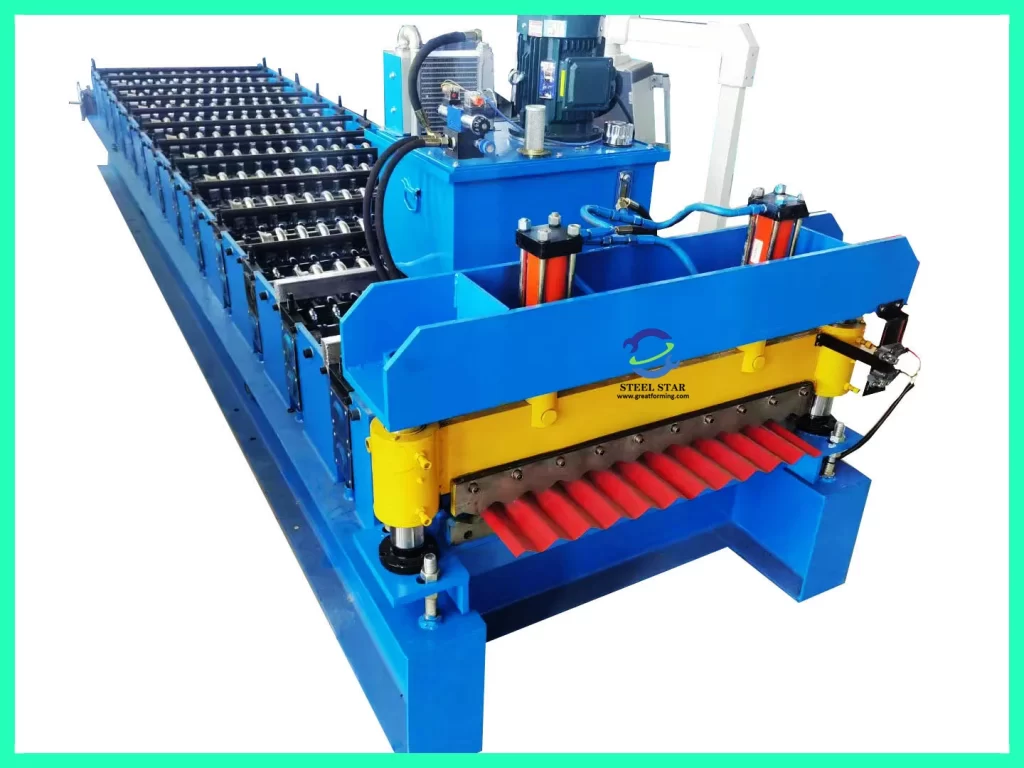

Among the diverse family of roll forming equipment, one machine type occupies a singular position in both industrial history and contemporary manufacturing. The corrugated profile machine, which produces the familiar wave-patterned sheets that shelter countless buildings worldwide, represents roll forming in its most essential form—and yet, beneath its apparent simplicity lies sophisticated engineering developed over more than a century of continuous refinement.

Corrugated metal sheets are so ubiquitous that they are often taken for granted. They line agricultural barns and urban warehouses, form temporary barriers at construction sites, and provide durable cladding for factories across every continent. Behind each stack of sheets awaiting shipment is a corrugated profile machine that has transformed flat steel into engineered panels with precise geometry, consistent mechanical properties, and cut lengths tailored to specific building requirements. This article examines the technology, applications, and commercial considerations surrounding these indispensable manufacturing systems.

Defining the Corrugated Profile

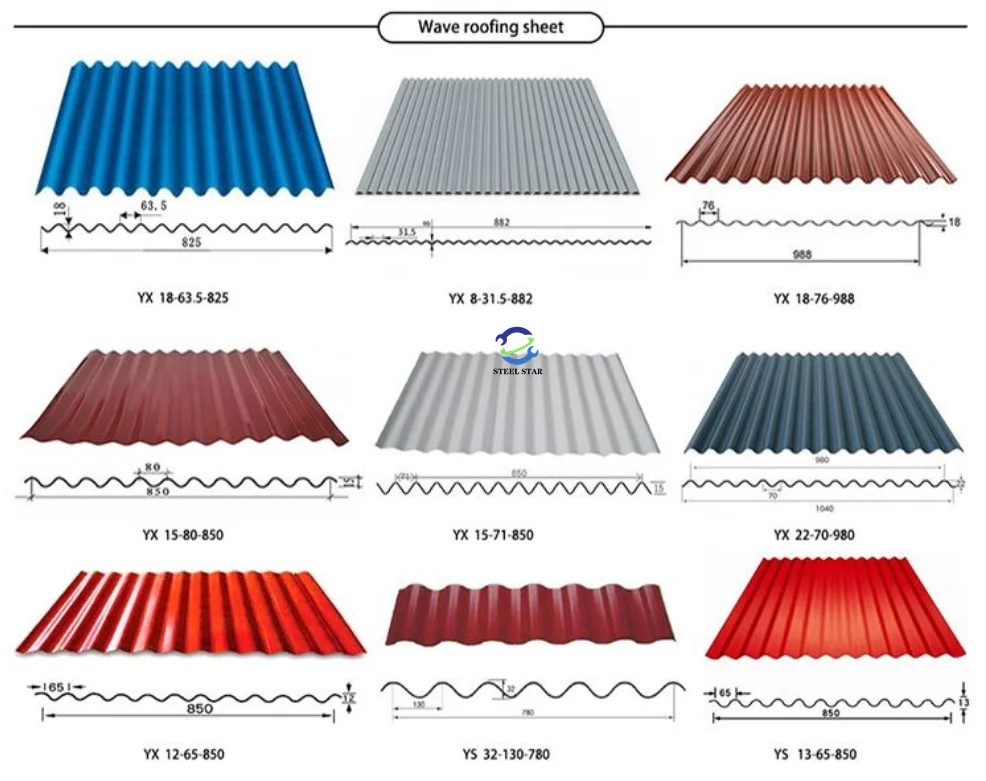

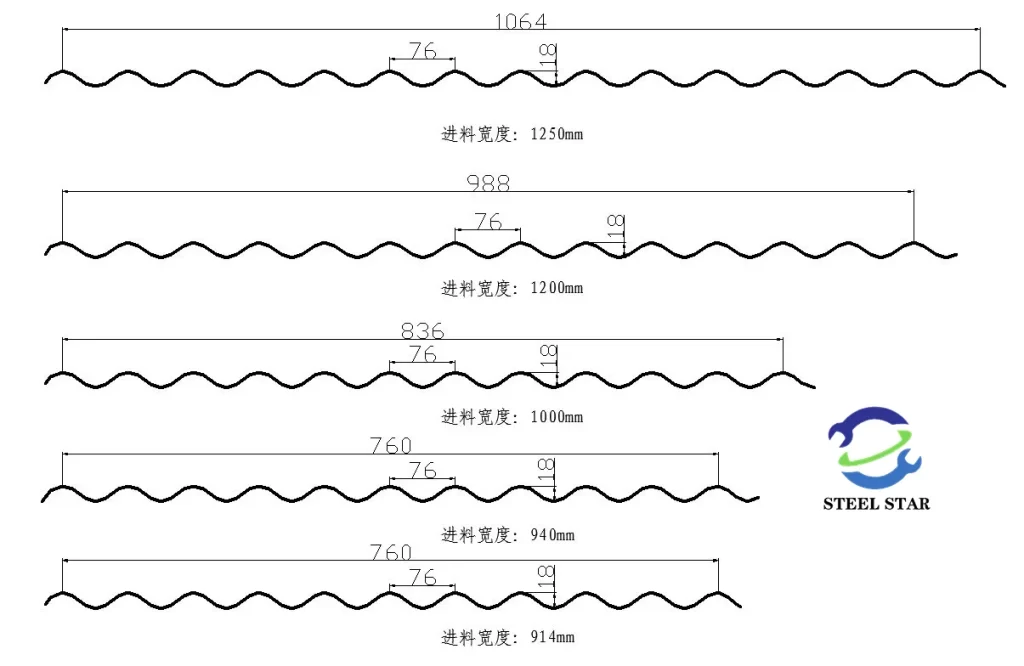

Before examining the machines that produce corrugated sheets, it is necessary to understand what distinguishes a corrugated profile from other roll formed products. Corrugation refers to a series of parallel ridges and valleys running perpendicular to the length of the sheet, typically in a sinusoidal or arc-shaped pattern. This geometry imparts dramatically increased stiffness to thin-gauge metal, allowing lightweight sheets to span significant distances between supporting structures.

Standard corrugated profiles are defined by several parameters: pitch, the distance from the crest of one ridge to the next; depth, the vertical distance from valley to crest; and thickness, the base metal gauge. Common configurations include 3-inch by 1-inch corrugation (76 mm pitch by 25 mm depth), prevalent in North America; 7/8-inch corrugation, popular in agricultural applications; and metric profiles such as 76/18 and 177/51, widely specified in Europe and Asia.

Unlike architectural standing seam or insulated panel systems, corrugated sheets are typically installed with exposed fasteners, creating the distinctive ribbed appearance that has become synonymous with utilitarian metal construction. The profile’s effectiveness, low cost, and universal recognition have ensured its continued relevance despite the introduction of more complex panel systems.

The Corrugating Process

The transformation of flat strip into corrugated sheet appears deceptively straightforward. In practice, it requires precise control of material flow, careful roll design, and robust machine construction.

The process begins with a coil of metal—typically galvanized steel, Galvalume, or aluminum—mounted on a decoiler. The strip passes through a straightener or flattener to remove coil set, then enters the roll former. Within the machine, successive pairs of contoured rolls gradually shape the flat strip into the final corrugated pattern. Unlike many roll forming applications that involve multiple bends and complex cross-sections, corrugating is essentially a continuous bending operation. The strip is progressively formed into a series of parallel curves, with each roll station increasing the depth of the corrugations until the full profile is achieved.

The number of forming stations varies with material thickness, profile depth, and production requirements. Shallow profiles in light-gauge material may require only six to ten stations; deep profiles in heavy-gauge steel may require sixteen or more. Each station contributes a small increment of deformation, avoiding excessive strain that would cause buckling, work hardening, or surface marking.

After forming, the continuous corrugated strip passes through a flying shear that cuts panels to predetermined lengths without interrupting production. The cut sheets are then discharged to a stacking system, which accumulates panels for bundling and shipment.

Machine Configurations and Capabilities

Corrugated profile machines are manufactured in a range of configurations suited to different production volumes, material specifications, and end-use requirements.

Standard Duty Lines represent the most common configuration. These machines process material thicknesses from 0.3 mm to 0.8 mm at line speeds of 20 to 40 meters per minute. They are typically configured with manual or semi-automatic controls and are suitable for general construction, agricultural buildings, and light industrial applications. Standard duty lines are the entry point for many manufacturers and remain the backbone of the corrugated sheet industry.

Heavy Duty Lines are engineered for thicker materials, typically 0.8 mm to 1.5 mm or greater. These machines feature heavier mill frames, larger diameter shafts, higher horsepower drives, and more forming stations to accommodate the increased forces required to corrugate thick steel. They operate at slower speeds—typically 10 to 20 meters per minute—but produce panels with exceptional load-bearing capacity for industrial flooring, bridge decking, and heavy structural applications.

High-Speed Light Gauge Lines are optimized for maximum productivity in thin materials. Operating at speeds up to 60 meters per minute or more, these machines incorporate servo-driven flying shears, automatic stackers, and sophisticated control systems to maintain accuracy at elevated production rates. They are favored by large-scale manufacturers supplying high-volume markets such as residential roofing in developing economies.

Portable or Containerized Corrugators bring production directly to the job site. Mounted within standard shipping containers, these machines can be transported to remote locations or deployed for large-scale projects requiring on-site fabrication. Portable corrugators are extensively used in humanitarian shelter programs, military construction, and infrastructure development in regions lacking established building material supply chains.

Roll Tooling and Profile Versatility

A corrugated profile machine’s capability is defined by its roll tooling. Each profile geometry requires a dedicated set of rolls precisely machined to the specified contour. Manufacturers serving diverse markets often maintain multiple roll sets for different profiles, exchanging them as production requirements dictate.

Roll design is a specialized discipline combining mechanical engineering, materials science, and practical experience. The roll profile must account for springback—the tendency of metal to recover partially from deformation—requiring the rolls to overform slightly so that the finished panel relaxes to the intended geometry. Roll materials range from hardened tool steel for long production runs to chrome-plated or nickel-coated rolls for processing prepainted materials without surface damage.

Material Considerations and Coating Compatibility

The choice of input material significantly influences machine design, process parameters, and final product quality.

Galvanized Steel is the dominant material for corrugated sheets, offering excellent corrosion protection at modest cost. The zinc coating provides sacrificial protection at cut edges and scratches, an important consideration for exposed fastener applications. Coating weights are specified according to environmental severity, with Z100 (100 g/m²) suitable for dry interiors and Z275 (275 g/m²) recommended for marine or industrial exposures.

Galvalume, a coating of approximately 55% aluminum, 43.5% zinc, and 1.5% silicon, offers superior corrosion resistance, particularly in marine and industrial environments. The coating’s different surface characteristics may require adjustments to roll clearances and lubrication strategies.

Prepainted Steel introduces aesthetic considerations and surface protection requirements. The paint film, while durable, can be marred by improper roll finish or contaminated by metal particles. Corrugating prepainted material requires meticulously maintained rolls with appropriate surface treatments, as well as effective edge trimming and scrap management to prevent paint chips from adhering to finished panels.

Aluminum is specified where absolute corrosion resistance, light weight, or reflective cooling properties are required. Aluminum’s lower strength and tendency to gall require slower forming speeds and careful lubrication. Its higher material cost limits its application to premium market segments.

Ancillary Equipment and Production Integration

While the roll former is the centerpiece of the corrugating line, supporting equipment is equally critical to efficient production.

Coil Handling Systems range from simple manual decoilers to fully automated coil cars and loading tables. For high-volume production, double-end decoilers permit loading of fresh coils while the current coil continues to feed, eliminating downtime for coil changes.

Loop Control Systems maintain a free-hanging loop of material between the decoiler and roll former, isolating the forming process from variations in coil payoff tension. Photoelectric sensors or mechanical dancer arms regulate decoiler speed to maintain consistent loop geometry.

Servo Flying Shears have largely replaced hydraulic and pneumatic shears in modern machines. Servo drives provide exceptional cut length accuracy, rapid acceleration and deceleration, and precise synchronization with line speed. Advanced systems can execute multiple cut lengths within a single production run without interruption.

Automated Stacking Systems receive cut panels, accumulate them into bundles of specified quantities, and present the bundles for strapping and removal. Magnetic stackers are effective for ferrous materials; vacuum stackers accommodate both ferrous and non-ferrous panels. Proper stacking is essential for product protection and labor efficiency.

Digital Controls and Industry 4.0 Integration

Contemporary corrugated profile machines are distinguished as much by their software as by their mechanical construction.

PLC-Based Control Systems manage all aspects of machine operation, from decoiler speed synchronization to shear actuation to stacking sequence. Operator interfaces provide real-time production data, fault diagnostics, and parameter adjustment capabilities.

Production Monitoring and Analytics systems collect machine data for analysis. Production rates, downtime events, material consumption, and quality metrics are displayed on operator dashboards and reported to management systems. Predictive maintenance algorithms analyze machine performance trends to anticipate maintenance requirements before failures occur.

Remote Service Capabilities allow machine builders to connect to customer equipment for diagnostics, software updates, and troubleshooting. This capability is particularly valuable for manufacturers in remote locations or regions with limited local technical support.

Facility and Infrastructure Requirements

Corrugated profile machines impose specific demands on the production facility.

Space Requirements vary with line configuration and panel length. A complete corrugating line requires approximately 30 to 40 meters of continuous floor space from coil entry to panel stacker, plus additional area for coil storage and finished goods inventory. Ceiling height must accommodate overhead cranes or coil handling equipment.

Electrical Service must supply adequate power for main drives, servo systems, and ancillary equipment. Three-phase power is universal; specific voltage and frequency requirements depend on the machine builder and destination country.

Compressed Air is required for mandrel expansion, shear actuation, and various accessory functions. A dedicated air compressor with adequate capacity and proper drying equipment ensures reliable operation of pneumatic components.

Material Handling Equipment for coil loading and finished goods removal is essential. Coil weights typically range from 2 to 10 tons, requiring forklifts of appropriate capacity or overhead cranes. Coil ramps or coil cars facilitate safe loading onto decoiler mandrels.

Future Directions

The corrugated profile machine, despite its long history, continues to evolve. Several trends will shape its future development.

Energy Efficiency improvements in drive systems and process optimization will reduce operating costs and environmental impact. Regenerative drives that recover energy during deceleration are increasingly common.

Material Innovations including higher-strength steels, advanced metallic coatings, and integrated photovoltaic laminates will expand the applications for corrugated sheets and create new requirements for forming equipment.

Circular Economy Considerations are gaining attention. Machines capable of processing coil produced from recycled scrap, and designs that facilitate end-of-life separation and recycling of roofing materials, will become more important.

Democratization of Technology continues as machine builders in emerging markets develop increasingly sophisticated equipment at accessible price points. This trend expands access to modern manufacturing technology while intensifying competition among equipment suppliers.

The corrugated profile machine occupies a distinctive position in the spectrum of industrial equipment. It is simultaneously a commodity product—manufactured by dozens of companies worldwide in broadly similar configurations—and a highly specialized system requiring deep engineering expertise and meticulous attention to detail.

For those who operate them, corrugated profile machines represent the means of participating in one of the construction industry’s most stable and essential supply chains. The sheets they produce are rarely glamorous, seldom featured in architectural magazines, and almost never celebrated by design critics. Yet they cover more square meters of building area than any other cladding material. They keep rain from factories, grain from silos, and livestock from weather. They are, in the truest sense, the working uniform of the built environment.

The machines that make these sheets are accordingly utilitarian in the best sense—designed not for admiration but for reliable, efficient, sustained performance. A well-maintained corrugated profile machine, operated by knowledgeable personnel and supplied with quality material, will produce millions of square meters of roofing over its service life. It will start each morning with minimal preparation and continue until evening with consistent output. It will rarely seek attention and never demand appreciation. It will simply produce, day after day, the corrugated sheets that shelter the world.

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)