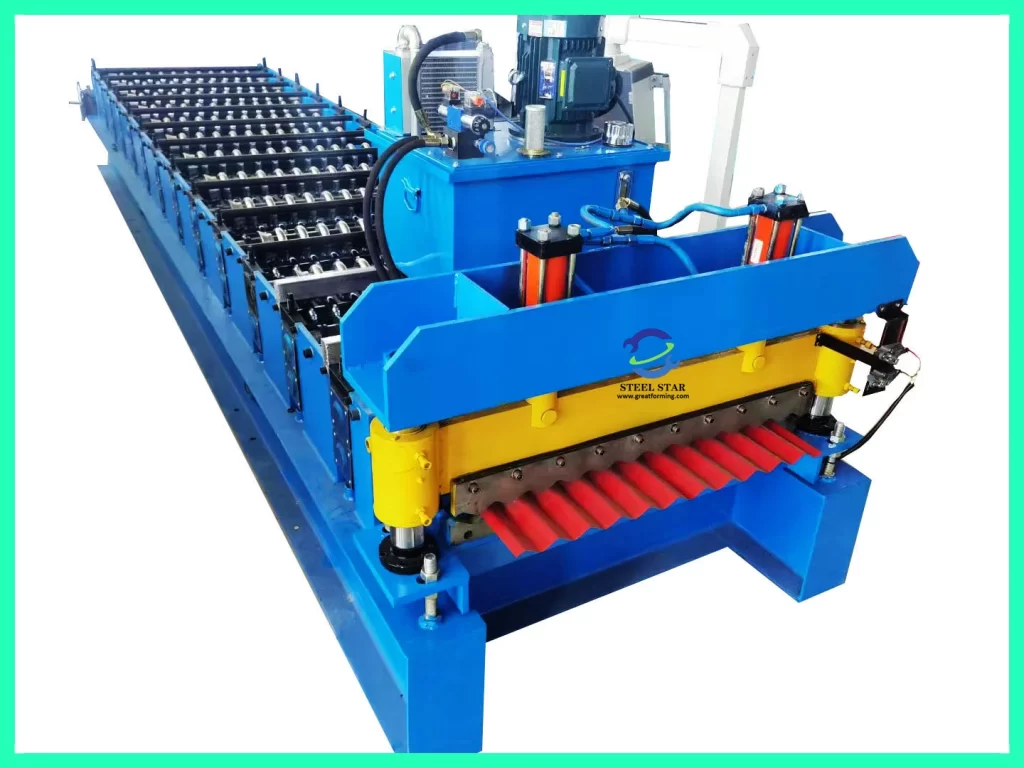

Corrugated Roll Forming Machine: Precision Engineering for Structural Strength

Introduction

The corrugated roll forming machine represents a pinnacle of industrial manufacturing technology, specifically engineered to transform flat metal sheets into robust corrugated profiles. These distinctive wave-like patterns are not merely aesthetic but serve critical structural and functional purposes across multiple industries. As a specialized subset of roll forming equipment, these machines deliver unparalleled efficiency, consistency, and material performance in producing one of the most versatile building and industrial components available today.

Technical Specifications and Mechanical Design

Core Working Principle

Operating on continuous cold-forming technology, the machine processes metal coils—typically galvanized steel, aluminum, or stainless steel—through a series of precisely engineered roller dies. Each station incrementally bends the material until it achieves the desired sinusoidal or trapezoidal waveform pattern. The process maintains material integrity while enhancing its mechanical properties through work hardening.

Key Configuration Parameters:

- Material thickness capacity: 0.3mm to 3.0mm

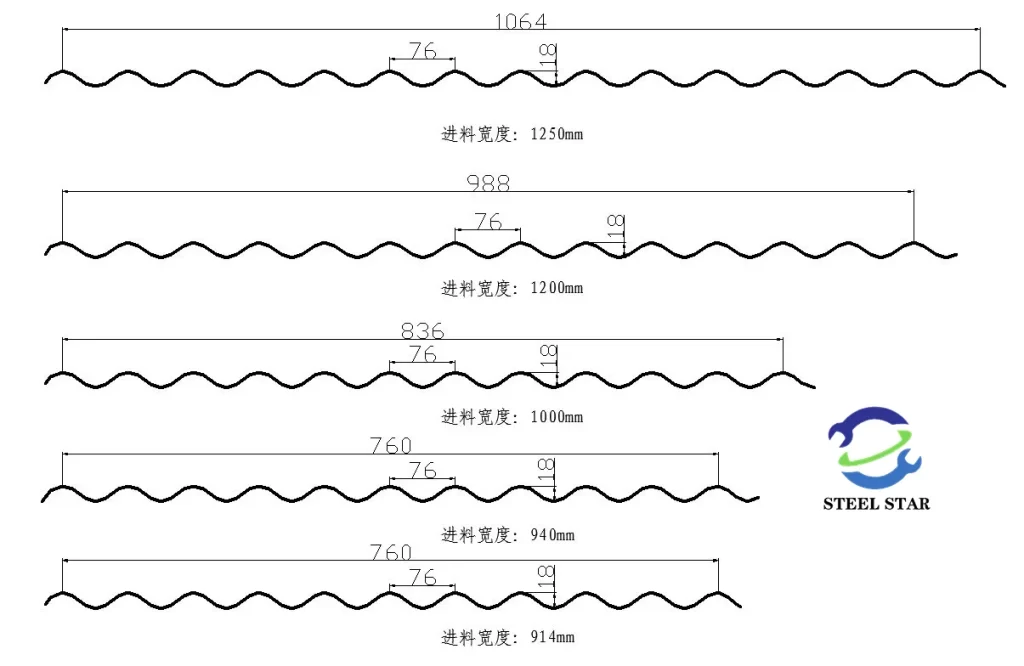

- Maximum coil width: 600mm to 1500mm

- Forming speed: 10-30 meters per minute

- Power requirements: 25-75 kW three-phase systems

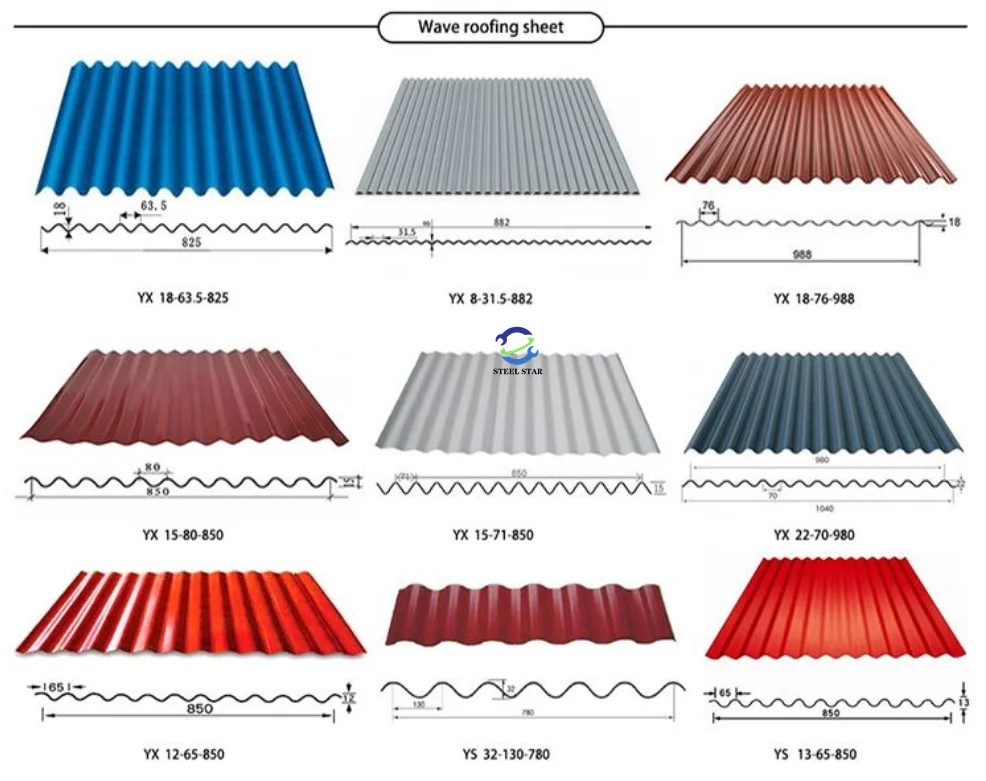

- Typical pitch dimensions: 25mm to 100mm

- Depth specifications: 8mm to 50mm

Mechanical Components and System Integration

1. Decoiler and Feeding System

- Heavy-duty mandrel with expanding segments

- Servo-controlled tension braking mechanisms

- Photoelectric edge guiding systems (±0.2mm accuracy)

- Automatic coil loading assist systems

2. Pre-processing Stations

- Multi-roller leveling assemblies (7-13 rolls)

- Hydraulic shear systems for lead-end trimming

- Surface cleaning and pretreatment units

- Digital length measurement encoders

3. Forming Section Architecture

- High-carbon chromium steel forming rolls (HRC 58-62)

- Modular quick-change cartridge designs

- Four-post guided roll stand configurations

- Centralized forced lubrication systems

- Temperature monitoring and cooling circuits

4. Post-forming Systems

- Rotary flying cutoff mechanisms

- Hydraulic discharge tables with stacking systems

- Automated packaging and bundling stations

- Real-time thickness monitoring (laser/LVDT sensors)

Industrial Applications and Product Versatility

Construction and Architecture

- Roofing and wall cladding systems

- Composite floor decking substrates

- Permanent formwork for concrete construction

- Acoustic and thermal insulation backing panels

- Architectural feature elements and sunscreens

Infrastructure and Transportation

- Highway drainage culverts and ditch liners

- Tunnel arch supports and lining systems

- Railroad car flooring and container construction

- Airport runway drainage solutions

Industrial Manufacturing

- Machinery guards and protective covers

- Material handling containers and pallets

- Industrial oven and furnace linings

- Agricultural equipment components

- Solar panel mounting structures

Performance Advantages and Economic Benefits

Material Science Advantages

- Cold working increases yield strength by 15-25%

- Maintains protective metallic coatings integrity

- Enables use of high-strength low-alloy (HSLA) steels

- Superior flatness retention compared to press braking

Production Efficiency Metrics

- 85-95% material utilization rates

- 300-500% productivity increase over press methods

- Continuous operation capability (24/7 with automation)

- Quick changeover systems (under 30 minutes)

Quality Consistency

- Profile consistency: ±0.15mm tolerance

- Angular accuracy: ±0.5 degree maintenance

- Surface finish preservation (minimal scratching)

- Predictable springback compensation

Technological Innovations and Smart Features

Advanced Control Systems

- PLC with HMI touchscreen interfaces

- Servo-driven precision positioning

- Automatic roll gap adjustment

- Production data tracking and reporting

Industry 4.0 Integration

- IoT connectivity for remote monitoring

- Predictive maintenance algorithms

- QR code tracking for material traceability

- Energy consumption optimization systems

Specialized Configurations

- Variable pitch corrugation capabilities

- Embossing and perforating inline units

- Multi-layer composite material handling

- Special surface treatment integration

Operational Considerations and Best Practices

Installation Requirements

- Foundation specifications: 300mm reinforced concrete

- Environmental controls: temperature ±5°C, humidity <70%

- Minimum operational space: 30m length × 5m width

- Crane access requirements: 3-10 ton capacity

Maintenance Protocols

- Daily inspection checklist implementation

- Bearing lubrication schedules (300-500 operating hours)

- Roll surface inspection and refinishing procedures

- Alignment verification protocols (quarterly)

Safety Systems

- Light curtain protection at entry/exit points

- Emergency stop circuits with redundant monitoring

- Noise enclosure options (85 dB reduction capability)

- Electrical safety isolation systems

Market Dynamics and Industry Trends

Current Market Position

The global corrugated roll forming equipment market is valued at approximately $850 million, with projected growth of 5.2% CAGR through 2028. Asia-Pacific regions account for 45% of new installations, driven by infrastructure development and manufacturing expansion.

Sustainability Developments

- Energy recovery systems implementation

- Water-based lubricant adoption

- Recycled material processing capabilities

- Carbon footprint tracking integration

Future Technological Directions

- AI-based quality control vision systems

- Hybrid forming (combined roll and press technology)

- Advanced simulation software integration

- Nano-coating compatibility developments

Selection Criteria and Investment Analysis

Technical Evaluation Factors

- Material range requirements assessment

- Annual production volume projections

- Product diversification needs

- Facility infrastructure limitations

- Technical support availability

Financial Considerations

- ROI period: Typically 18-36 months

- Operating cost structure analysis

- Depreciation and tax advantage calculations

Vendor Assessment Points

- Industry experience and reference projects

- Spare parts availability and lead times

- Training program comprehensiveness

- Service response time guarantees

The modern corrugated roll forming machine embodies the convergence of mechanical engineering excellence, materials science advancement, and digital control sophistication. Its ability to transform basic metal sheets into high-performance structural components with remarkable efficiency and precision makes it indispensable across numerous industrial sectors. As manufacturing continues evolving toward smarter, more sustainable practices, these machines are adapting through enhanced connectivity, greater flexibility, and improved energy efficiency. The continued innovation in corrugated roll forming technology promises to unlock new applications and performance standards, solidifying its position as a cornerstone of modern industrial manufacturing infrastructure. Future developments will likely focus on further reducing setup times, expanding material compatibility, and deepening integration with digital manufacturing ecosystems, ensuring these machines remain vital tools in global industrial production for decades to come.

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)