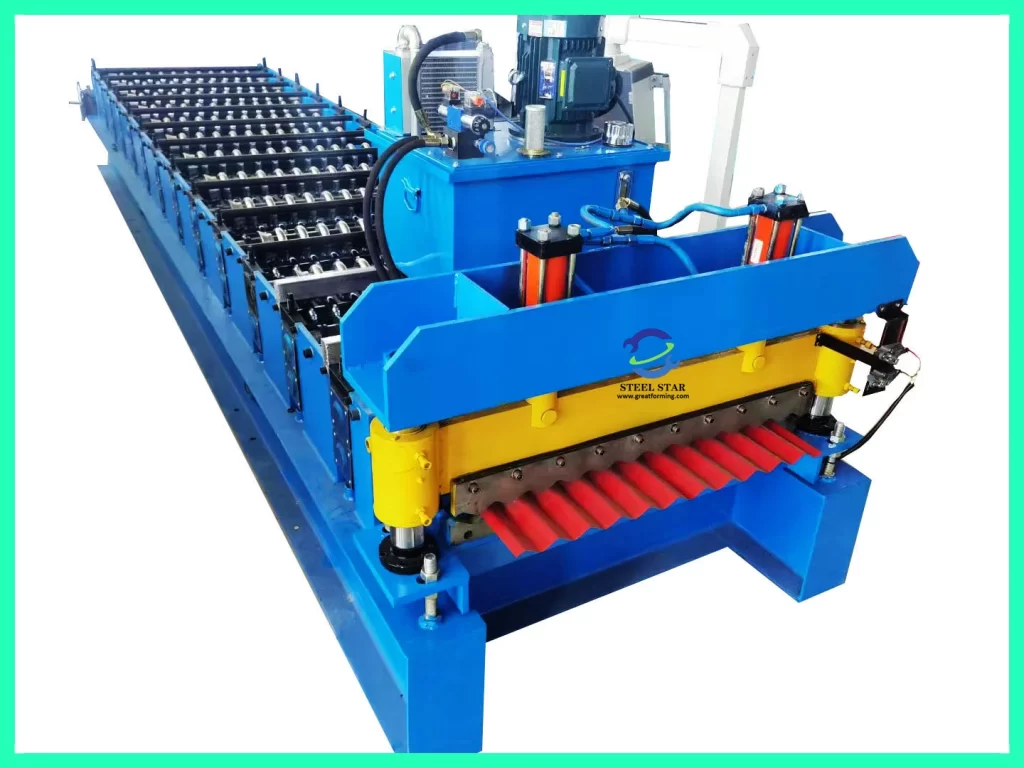

Corrugated Sheet Forming Machine: A Comprehensive Overview

Corrugated sheet forming machines represent a cornerstone technology in modern manufacturing, transforming flat metal coils into versatile corrugated profiles used across industries. These machines have revolutionized construction, automotive, and packaging sectors by enabling efficient, high-volume production of durable corrugated sheets.

What is a Corrugated Sheet Forming Machine?

A corrugated sheet forming machine is a specialized roll forming system designed to produce metal or plastic sheets with repetitive wave-like patterns (corrugations). These corrugations dramatically increase the material’s strength-to-weight ratio while maintaining flexibility in certain applications.

Key Components and Working Principle

- Decoiler System: Unwinds and feeds the flat coil material into the machine

- Pre-punching/Notching Station (Optional): Adds holes or cutouts before forming

- Roll Forming Section: A series of precisely engineered roll stations gradually shape the flat material into the desired corrugated profile

- Cutting Mechanism: Flying shear or hydraulic cut-off system for length customization

- Control System: Computerized controls for precision operation and automation

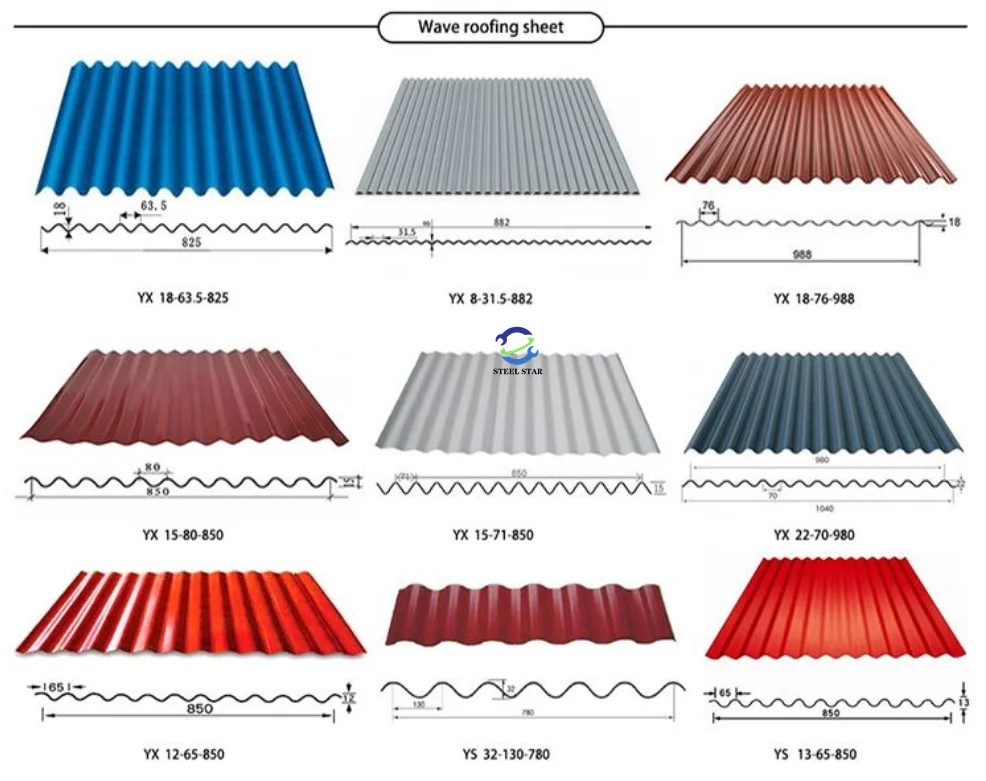

Types of Corrugated Profiles

Modern machines can produce various corrugation patterns:

- Classic Wave Pattern: Traditional sinusoidal curves

- Box Profile: Angular, trapezoidal designs

- Tile Pattern: Aesthetic profiles mimicking traditional roofing

- Custom Geometries: Engineered for specific structural or aesthetic requirements

Materials and Applications

Common Materials:

- Galvanized steel

- Aluminum

- Pre-painted steel (PPGI/PPGL)

- Zinc-aluminum alloys

- Certain polymers

Primary Applications:

- Construction: Roofing, wall cladding, and structural panels

- Industrial: Warehouse roofing, factory buildings, and agricultural structures

- Transportation: Trailer linings, cargo protection, and specialized containers

- Infrastructure: Sound barriers, temporary shelters, and drainage systems

Technical Advancements

Modern corrugated sheet forming machines incorporate several innovations:

Automation and Control

- PLC-based systems with touchscreen interfaces

- Servo-driven precision cutting

- Real-time production monitoring

- Automatic fault detection and diagnostics

Flexible Manufacturing

- Quick-change tooling systems

- Adjustable roll configurations

- Multi-profile capabilities

- Digital pattern libraries

Quality Enhancement

- Integrated surface protection

- Tension control systems

- Vibration reduction technology

- Thermal compensation mechanisms

Production Capabilities

Standard machines typically offer:

- Speed: 10-60 meters per minute

- Material thickness: 0.2-1.2 mm

- Sheet width: 600-1250 mm

- Custom length cutting with ±1 mm accuracy

Benefits of Modern Machines

- High Efficiency: Continuous production with minimal downtime

- Material Optimization: Reduced waste through precision forming

- Consistent Quality: Uniform profiles with tight tolerances

- Labor Savings: Automated operation requiring minimal supervision

- Versatility: Multiple profiles from a single machine

Selection Considerations

When choosing a corrugated sheet forming machine, consider:

- Production Requirements

- Volume and speed needs

- Material types and thickness range

- Profile complexity

- Technical Specifications

- Motor power and drive systems

- Control system sophistication

- Tooling quality and availability

- Supplier Factors

- Manufacturer reputation and experience

- After-sales service and support

- Training and documentation

- Spare parts availability

- Economic Factors

- Initial investment cost

- Operating expenses

- Maintenance requirements

- Return on investment calculation

Safety Features

Modern machines incorporate multiple safety systems:

- Emergency stop circuits

- Safety guarding with interlocks

- Overload protection

- Electrical insulation

- Operator safety training requirements

Maintenance Requirements

Proper maintenance ensures longevity:

- Daily: Cleaning and visual inspection

- Weekly: Lubrication and bolt tightening

- Monthly: Roll inspection and alignment checks

- Annual: Comprehensive overhaul and calibration

Industry Trends and Future Developments

- Smart Manufacturing: Integration with Industry 4.0 systems

- Sustainability: Energy-efficient drives and recyclable materials focus

- Digitalization: IoT connectivity for predictive maintenance

- Advanced Materials: Compatibility with new alloys and composites

- Customization: Growing demand for specialized profiles

Environmental Considerations

Modern machines address environmental concerns through:

- Energy-efficient motors and drives

- Noise reduction technology

- Scrap collection and recycling systems

- Compliance with international environmental standards

Corrugated sheet forming machines have evolved from simple mechanical devices to sophisticated, computer-controlled systems that form the backbone of modern sheet metal processing. Their ability to efficiently transform flat materials into strong, functional profiles makes them indispensable in numerous industries. As technology advances, these machines continue to offer greater precision, flexibility, and efficiency, driving innovation in product design and manufacturing processes worldwide. The future promises even more intelligent, sustainable, and versatile corrugated sheet forming solutions as manufacturers respond to evolving market demands and technological possibilities.

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)