The Corrugated Sheet Machine: An Industrial Workhorse for Global Construction

The Corrugated Sheet Machine stands as one of the most enduring and essential pieces of equipment in the metal fabrication industry. Dedicated to producing the iconic wavy-profile sheets used worldwide, this machine transforms flat metal coils into durable, structurally efficient panels that form the roofs and walls of everything from agricultural barns and industrial warehouses to residential sheds and contemporary architectural facades. Its operation represents a perfect marriage of mechanical simplicity, production efficiency, and functional engineering.

Core Function and Product Output

A Corrugated Sheet Machine is a continuous cold roll-forming line specifically engineered to manufacture corrugated metal sheets. It takes a coil of flat-rolled steel, aluminum, or other alloy and progressively bends it into a uniform, repeating sinusoidal or trapezoidal wave pattern. This corrugation process is not merely aesthetic; it geometrically enhances the panel’s stiffness and load-bearing capacity through form strength, allowing a relatively thin sheet to span significant distances.

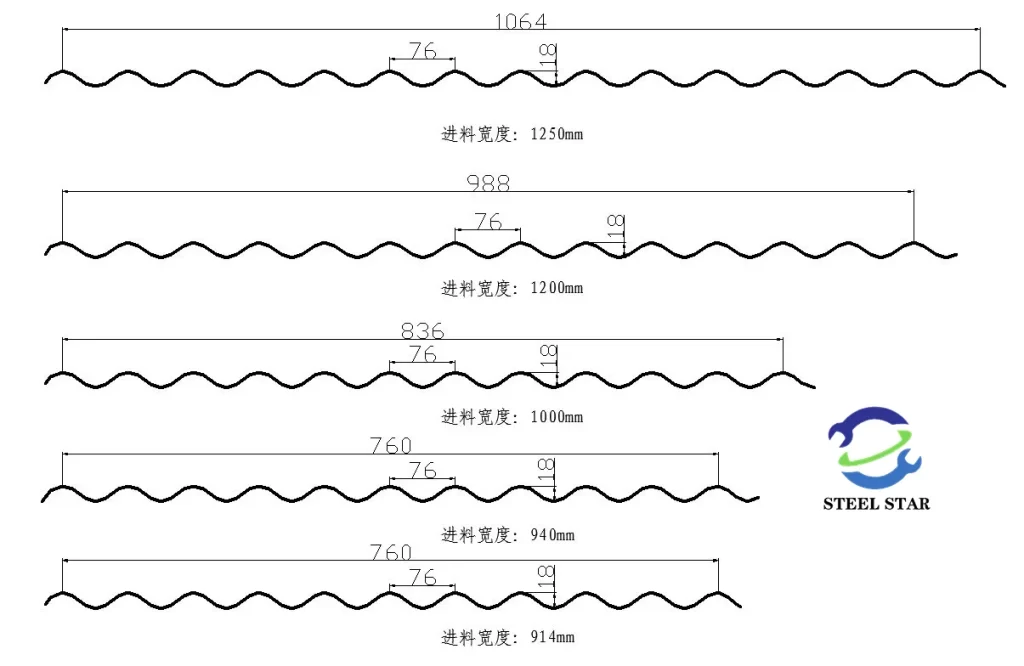

Typical profiles produced include:

- Round Corrugation: The classic sinusoidal wave pattern.

- Trapezoidal Corrugation: Features angular, flat-topped ridges for a more modern look and often greater rigidity.

- Custom Wave Designs: Variants with specific pitches (distance between crests) and depths to meet regional standards or special architectural requirements.

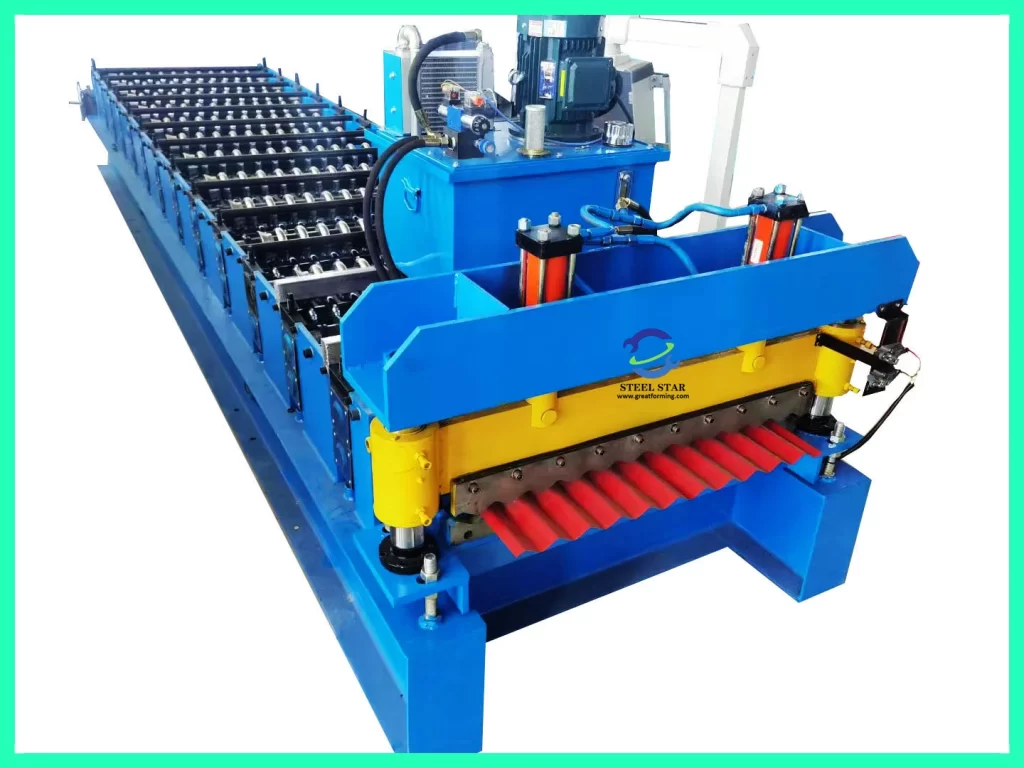

Anatomy of a Standard Production Line

The machine integrates several key components into a seamless workflow:

- Decoiler & Feeder: A robust mandrel holds the master coil, which is fed into the machine. A levelling or straightening unit ensures the metal strip is perfectly flat before forming, which is critical for uniform corrugation.

- Pre-Punching Station (Optional): For sheets requiring vent holes or specific fastening points, a punching unit can be integrated to add these features to the flat strip before it is corrugated, ensuring perfect placement.

- The Heart: The Roll Forming Mill: This is a sequential series of roll stands. Each stand contains a set of precision-machined, hardened steel rollers with a progressively deeper impression of the final corrugation profile. As the metal passes through each station, it is incrementally bent until the full wave pattern is achieved. The number of forming stands determines the smoothness and accuracy of the final bends.

- Cut-Off System: Once formed, the continuous corrugated sheet is cut to precise, pre-set lengths. This is typically done by a flying cut-off system—a hydraulic shear or rotary saw that moves synchronously with the moving sheet to make a clean, square cut without stopping the production line.

- Run-Out Table & Stacker: The finished sheets are conveyed to an automatic stacking station, where they are counted, aligned, and bundled for strapping and shipping.

Key Advantages and Industrial Impact

- Exceptional Structural Efficiency: The corrugated profile provides high strength and rigidity with minimal material use, offering an outstanding strength-to-weight ratio.

- Superior Water Shedding: The pronounced channels efficiently drain rainwater and snow melt, making it a highly reliable and time-tested roofing solution.

- High-Speed, Cost-Effective Production: These machines are optimized for volume, capable of producing sheets at high linear speeds (e.g., 30-70 meters per minute), resulting in very low per-unit manufacturing costs.

- Durability and Low Maintenance: When fabricated from galvanized or painted coils, the sheets offer excellent resistance to corrosion and require minimal upkeep.

- Proven Versatility: The basic product is used across countless sectors—agriculture, industry, logistics, and retail—and can be adapted with different materials, coatings, and colors.

Technical Considerations for Selection

When evaluating a corrugated sheet machine, buyers must consider:

- Profile Specification: The exact wave shape, pitch, and depth the machine is tooled to produce.

- Material Capacity: Supported coil width, metal type (GI, GL, Aluminum), and thickness range (e.g., 0.25mm to 1.2mm).

- Production Speed & Automation: Required output (tons/shift) and the desired level of automation in cutting, stacking, and control.

- Tooling Quality: The precision and durability of the forming rollers, which are critical for product consistency and long-term machine performance.

- Control System: Modern PLC-based controls for easy adjustment of length, count, and speed, and for monitoring production data.

The Corrugated Sheet Machine is a testament to the power of practical engineering. It reliably produces one of the most ubiquitous and functional building materials in the world. While architectural trends evolve, the fundamental benefits of the corrugated sheet—strength, economy, weather resistance, and ease of installation—ensure its permanent place in construction. The machines that manufacture them continue to be refined for greater efficiency and flexibility, ensuring that this classic profile will continue to provide durable and cost-effective shelter for structures worldwide, embodying the principle that sometimes the simplest solutions are the most enduring.

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)