The Steel Corrugated Sheet Making Machine: Shaping the Skin of Modern Construction

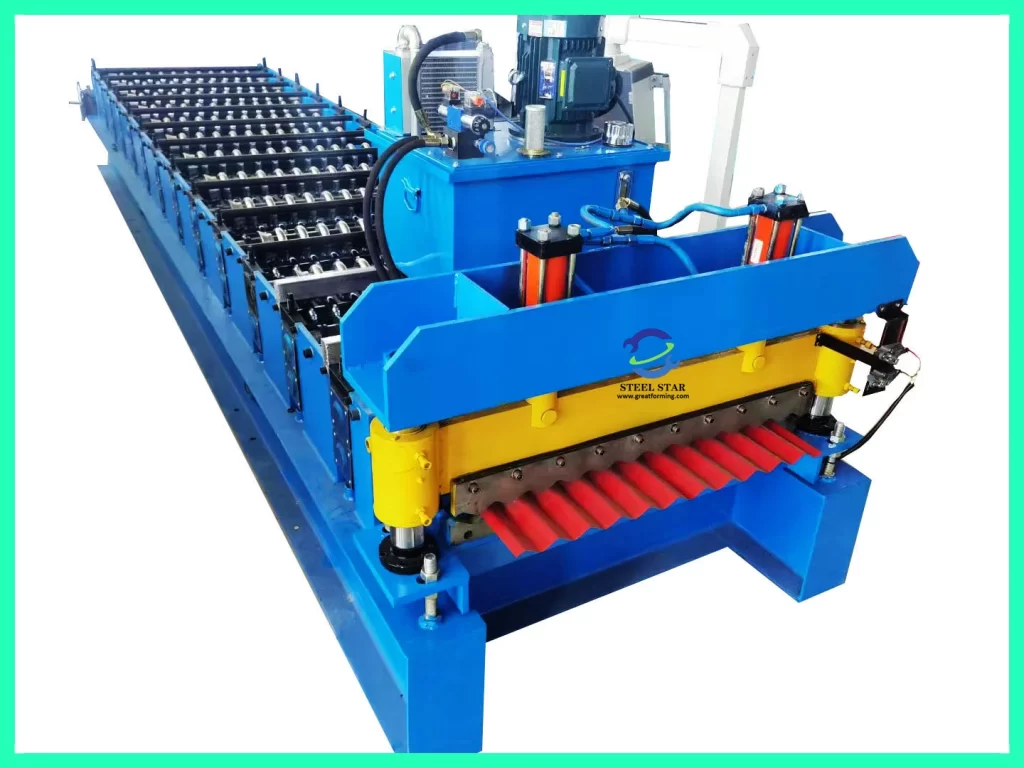

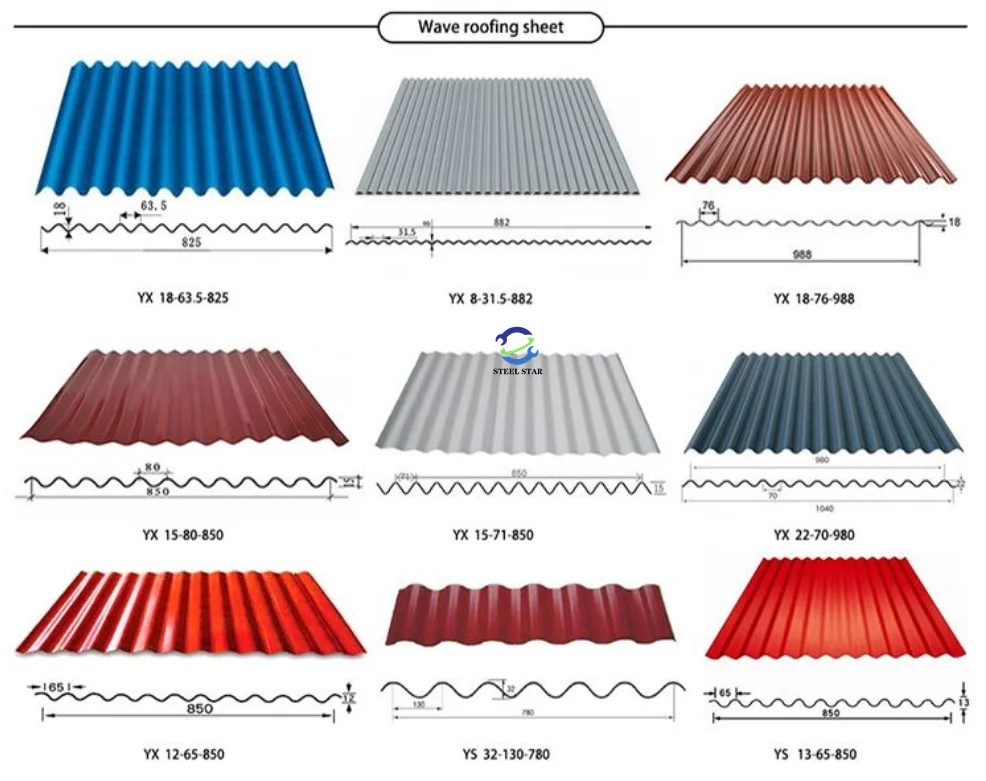

Unlike its paper-based namesake, the Steel Corrugated Sheet Making Machine is a powerhouse of metal forming, dedicated to producing the iconic profiled sheets used in roofing, cladding, and structural applications worldwide. This machine transforms flat steel coils into durable, rigid panels with consistent, repeating trapezoidal or sinusoidal patterns, combining strength, weather resistance, and architectural appeal.

Core Principle and Process Flow

The operation is a continuous, cold-rolling process known as roll forming. It is highly automated and efficient, designed for long production runs.

- Uncoiling & Leveling: The process starts with a heavy coil of pre-finished steel (galvanized, galvalume, or prepainted) mounted on an uncoiler. The steel strip is fed into a leveling unit, which removes any coil curvature or internal stresses, ensuring a perfectly flat sheet enters the forming stage.

- Pre-Punching/Notching (Optional): For sheets requiring specific fixings or aesthetic features, the flat strip may pass through a servo-controlled punching station. This unit can precisely punch holes, create notches, or add embossed patterns before the sheet is corrugated.

- The Heart: The Roll Forming Mill: This is the core of the machine. The flat strip is progressively shaped by passing through a series of paired roller dies (stands), typically between 10 to 20 sets. Each stand of rolls incrementally bends the metal a few degrees more than the last, gradually forming the final corrugation profile without stretching or thinning the material. This gradual process ensures precise geometry and minimizes springback.

- Cutting to Length: After forming, the now-continuous corrugated sheet passes through a cutting system. Most modern machines use a flying cut-off unit—a synchronized traveling shear that cuts the moving sheet to preset lengths without stopping the production line, ensuring high productivity and square, burr-free ends.

- Output & Stacking: The finished sheets are automatically conveyed to a stacking station. They are aligned, counted, and bundled for strapping, ready for shipment.

Key Components and Technological Features

- Roll Forming Mill: The precision-ground, hardened steel roller dies are custom-designed for each specific profile (e.g., 32mm, 40mm trapezoidal, tile-effect). They are mounted on a sturdy frame to withstand high forming forces.

- PLC Control System: The entire line—from decoiler speed and roll stand synchronization to flying cut length—is managed by a Programmable Logic Controller. This ensures consistent quality and allows for quick parameter changes for different sheet lengths.

- High-Speed Operation: Modern lines can operate at speeds exceeding 100 meters per minute, producing thousands of square meters of sheeting per shift.

- Material Flexibility: Advanced machines can handle a wide range of steel grades and thicknesses (commonly 0.3mm to 1.2mm) and various protective coatings.

Importance and Applications

The machine’s product is fundamental to global construction. Corrugated steel sheets offer exceptional strength-to-weight ratio, longevity, and ease of installation. They are the primary material for:

- Industrial & Commercial Roofing: Providing large, weathertight covers for warehouses, factories, and airports.

- Wall Cladding: Offering both protective and aesthetic facades.

- Composite Panels: As the outer skin for insulated sandwich panels.

- Agricultural Buildings: Sheds, barns, and storage facilities.

Advancements

Modern machines integrate servo-electric drives for greater accuracy and energy efficiency, in-line automatic profile change systems for flexibility, and laser cutting options for complex end cuts or penetrations. Quality monitoring systems use lasers to check profile dimensions in real-time.

In summary, the Steel Corrugated Sheet Making Machine is a quintessential example of efficient, continuous manufacturing. Through the precise, progressive art of roll forming, it delivers the robust, economical, and versatile building envelope products that define the modern industrial and architectural landscape. Its relentless output literally shapes the roofs over our heads and the walls around us.

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)