The Custom Roll Forming Machine: Engineering Bespoke Metal Profiles.

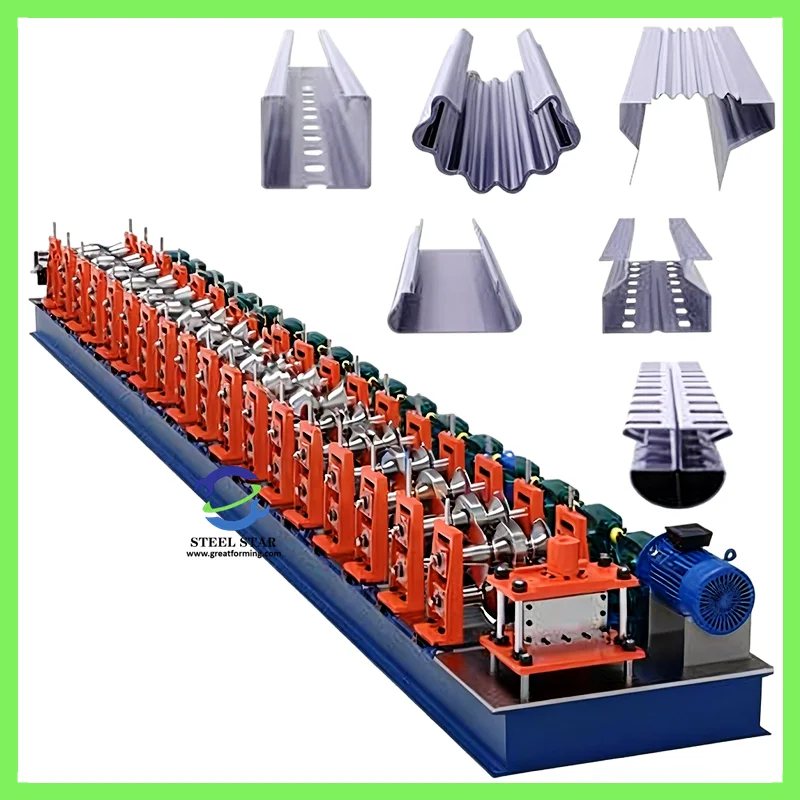

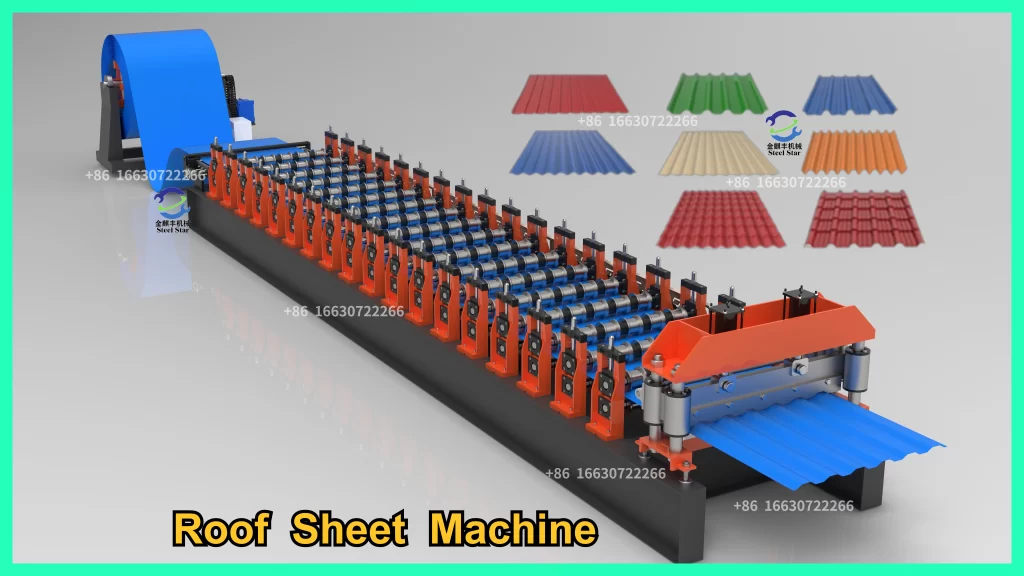

In the world of industrial manufacturing, the standard roll forming machine is a marvel of mass production, efficiently creating countless linear feet of common profiles like C-channels, Z-purlins, and decking. However, many industries—from aerospace and automotive to specialized construction and consumer goods—require unique, proprietary metal shapes that define their products’ function, performance, and aesthetic. Enter the Custom Roll Forming Machine: a highly engineered, application-specific system designed not for volume of a single shape, but for the precision creation of a unique one.

This machine represents the pinnacle of collaborative engineering between manufacturer and client. It is not an off-the-shelf product but a co-created solution, translating a specific profile drawing into a fully functional production line. This article delves into the philosophy, design, application, and economic rationale behind these bespoke industrial workhorses.

1. The Philosophy of Customization: When Off-the-Shelf Won’t Do

A custom roll forming machine is commissioned when a profile cannot be produced on a universal or standard machine, or when doing so would be economically or technically inefficient. The driving factors include:

- Unique Profile Geometry: The shape is proprietary, with complex curves, multiple bends, tight tolerances, or unique features (e.g., integrated snap-fits, seals, or functional ribs).

- Material Specifics: The application requires forming specialized alloys (high-strength steel, titanium, aluminum, pre-painted or clad materials) with specific springback and formability characteristics.

- Integrated Secondary Operations: The production process requires in-line punching, embossing, welding, sealing, or cutting of a complexity beyond standard auxiliary units.

- Unmatched Precision & Consistency: The part’s end-use (e.g., a structural component in an aircraft or a critical seal in an appliance) demands tolerances achievable only with a machine engineered solely for that profile.

- Production Volume: While custom machines have a high initial cost, for a high-volume, long-term production run of a single complex profile, they offer unbeatable per-part efficiency and quality control.

2. The Collaborative Design and Build Process

Creating a custom machine is a phased, iterative partnership:

- Phase 1: Profile & Requirement Analysis. Engineers scrutinize the client’s 2D/3D profile design, material specs, tolerances, annual volume, and desired line speed. They perform finite element analysis (FEA) and roll forming simulation software modeling to predict material flow, stresses, and springback, virtually validating the process before metal is cut.

- Phase 2: Machine Conceptualization. Based on analysis, engineers design the complete system:

- Roll Tooling Design: The most critical element. The number of forming stations (often 12-30+) is calculated to achieve the shape progressively and gently. Each pair of rolls is meticulously designed and CNC-machined from hardened tool steel or carbide.

- Line Configuration: Determines the needed components: decoiler type, pre-punching/notching systems, the main forming mill, in-line process stations (e.g., hole piercing, lamination, welding), cut-off method (flying shear, rotary cut, servo cut), and stacking mechanism.

- Phase 3: Fabrication & Assembly. The machine frame, drives, and components are built. The custom roll sets are machined, heat-treated, ground, and polished to mirror finishes to minimize friction and marking.

- Phase 4: Factory Acceptance Testing (FAT). The client witnesses a full production run at the builder’s facility. The machine is tuned to produce sample parts that are measured and tested against all specifications.

- Phase 5: Installation & Training. The machine is installed on-site, commissioned, and client personnel are trained on its operation, maintenance, and tooling changeover procedures.

3. Key Technical Features of a Custom Machine

- High-Stiffness Mill Stands: To maintain extreme tolerances (often ±0.1mm or better), the mill housing is massively built to resist deflection under forming loads.

- Advanced Drive Systems: Servo-electric drives for individual roll stations or sections provide unparalleled synchronization and control over forming speed at each stage, crucial for complex shapes.

- Precision Tooling: Custom profiles require custom rolls. These are designed with precise roll diameters, gaps, and alignments to control material guidance and minimize elongation or edge wave.

- Integrated Process Stations: The line is designed as a holistic system. Examples include:

- CNC Rotary Punching: For holes placed on the profile’s face or flange during the forming process.

- In-Line Welding: To create closed sections (e.g., from a custom “C” to a custom “O” tube).

- Embossing/Louvering: Adding functional or decorative features in-line.

- Sophisticated Controls & Monitoring: The PLC/HMI system is programmed for the specific profile, with recipes for different lengths and integrated diagnostic sensors for pressure, alignment, and temperature.

4. Iconic Applications

Custom roll forming machines are behind countless specialized products:

- Automotive: Window/door frames, seat track rails, bumper beams, structural reinforcement channels.

- Aerospace: Stringers, airframe components, and interior trim profiles.

- Building & Construction: Specialized curtain wall mullions, custom trim, solar panel mounting rails, unique standing seam roof profiles.

- Appliances: Refrigerator cabinet frames, oven cavities, washing machine drum reinforcements.

- Furniture & Storage: Adjustable shelving uprights, locker frames, display system components.

5. Economic and Strategic Rationale

The investment is substantial but justified by strategic advantages:

- Protected Intellectual Property (IP): The machine and its tooling produce a proprietary shape that competitors cannot easily replicate.

- Lower Total Cost per Part: For high volumes, the automation, speed, and material efficiency of a dedicated line outperform manual fabrication or multi-step processes.

- Supply Chain Control & Security: Brings a critical component manufacturing in-house, reducing dependency on external suppliers.

- Quality Assurance: Guarantees consistent, in-spec production, reducing scrap and warranty claims.

The custom roll forming machine is more than machinery; it is a physical manifestation of a product’s design intent. It bridges the gap between an engineer’s vision on a CAD screen and the physical reality of a high-volume, precision metal component. In a manufacturing landscape increasingly driven by differentiation and performance optimization, these machines serve as competitive arsenals for innovative companies.

They embody the principle that for the right application, the optimal manufacturing solution is not adapted, but created. By investing in a custom roll forming solution, a company doesn’t just buy a machine—it engineers a lasting competitive edge, one perfectly formed, unique profile at a time.

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)