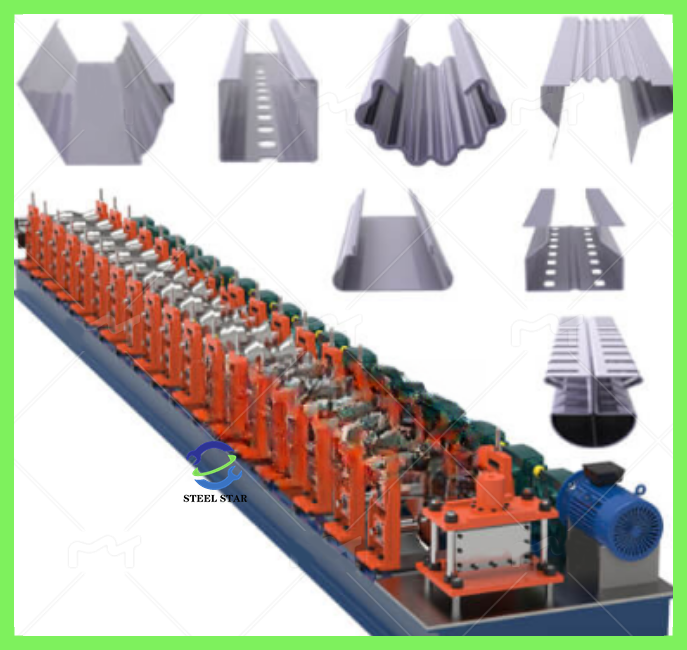

Custom Roll Forming Machines and Customized Machines are specialized solutions designed to meet unique production requirements, enabling companies to manufacture complex metal profiles or components that are not achievable with standard machinery. These machines are tailored to create specific shapes, handle diverse materials, or perform specialized processes, making them essential for industries requiring precise, unique, or non-standard profiles.

Custom Roll Forming Machines

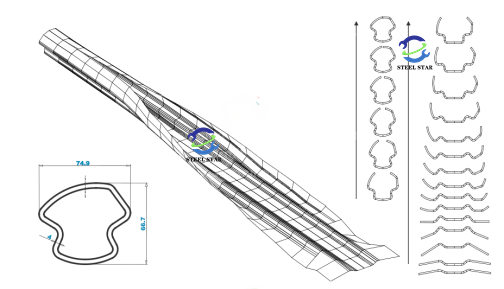

A Custom Roll Forming Machine is specifically designed and engineered to produce unique, customer-specified metal profiles. Unlike standard roll forming machines that make common profiles like channels, wall panels, or roofing sheets, custom roll forming machines are adapted to create intricate or atypical shapes.

Key Features:

- Custom Profile Design:

- Built to manufacture unique shapes, custom roll forming machines can create complex, multi-dimensional profiles based on specific client specifications.

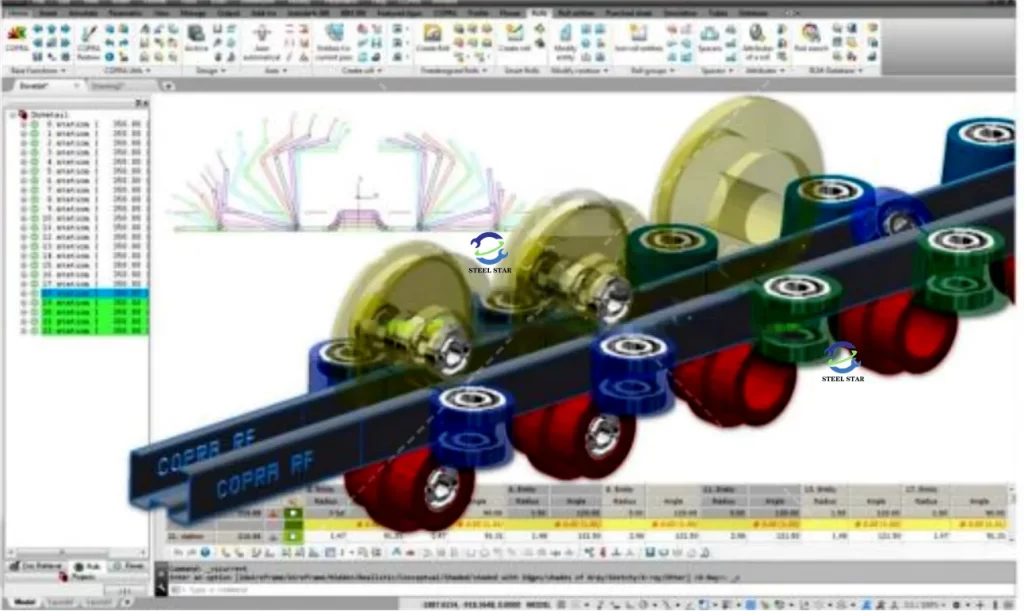

- Flexible Roller Setup:

- These machines come with rollers that can be precisely configured or modified to achieve the desired shape, allowing for highly customized profiles that meet specific dimensional or functional requirements.

- Advanced Automation and Control:

- They often integrate advanced PLC or CNC systems, enabling automated control over intricate processes, maintaining precision, and allowing for high production accuracy and consistency.

- Multi-Operation Integration:

- Custom machines can combine various processes, like punching, notching, embossing, or cutting, into a single line. This integration reduces processing time and minimizes the need for secondary operations.

Applications:

- Automotive: Creating unique car components such as frames, trims, and structural reinforcements.

- Construction: Custom beams, cladding, and other architectural metal components.

- Aerospace: Lightweight, high-strength custom profiles for aerospace structures.

- Electronics and Enclosures: Housing, frames, and custom shapes for electrical and electronic equipment.

Customized Machines

Customized Machines refer to machinery that is not limited to roll forming but can be designed and adapted for various production needs across different industries. These machines might combine elements from different processing methods, include specialized tooling, or integrate unique features to meet exact requirements for a particular application.

Key Features:

- Adapted to Specific Processes:

- Customized machines can be tailored to perform various tasks, such as laser cutting, punching, welding, or other manufacturing processes, depending on the production needs.

- Modular Design:

- They can be designed as modular systems, allowing companies to change, add, or remove specific operations as needed. This flexibility helps future-proof the machine, enabling it to adapt as product requirements evolve.

- Material Versatility:

- Customized machines can be engineered to handle a wide range of materials beyond metal, such as composites, plastics, or specialized alloys, expanding their usability across multiple sectors.

- Precision Engineering:

- These machines often use sophisticated control systems like CNC or PLCs for high accuracy and quality, especially useful in industries where tight tolerances are critical.

Applications:

- Medical Equipment: Precision machinery for components used in medical devices or implants.

- Consumer Goods and Appliances: Producing custom components, housing, or decorative parts for products like refrigerators or washing machines.

- Heavy Industry and Mining: Custom parts for industrial machinery or complex profiles for heavy equipment.

- Renewable Energy: Components for wind turbines, solar panel frames, or hydroelectric equipment.

Advantages of Custom and Customized Machines

- Highly Specialized Production: They enable manufacturing of unique, high-precision parts, reducing reliance on multiple machines.

- Increased Efficiency: By consolidating multiple processes, these machines can streamline production lines, minimize waste, and reduce lead times.

- Cost-Effectiveness: Customized machines reduce the need for outsourcing specific processes and lower operational costs over time.

- Scalability and Adaptability: Many custom machines can be adapted to meet changing requirements, allowing businesses to remain agile in response to new demands.

Choosing the Right Solution

Whether opting for a custom roll forming machine or a broader customized machine depends on the specific needs, industry requirements, and production goals. Custom roll forming machines are ideal for applications centered around continuous metal profiles, while fully customized machines cater to diverse, multi-step manufacturing processes across various materials and industries. Both provide tailored solutions that can improve efficiency, precision, and product quality for specialized manufacturing requirements.

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)