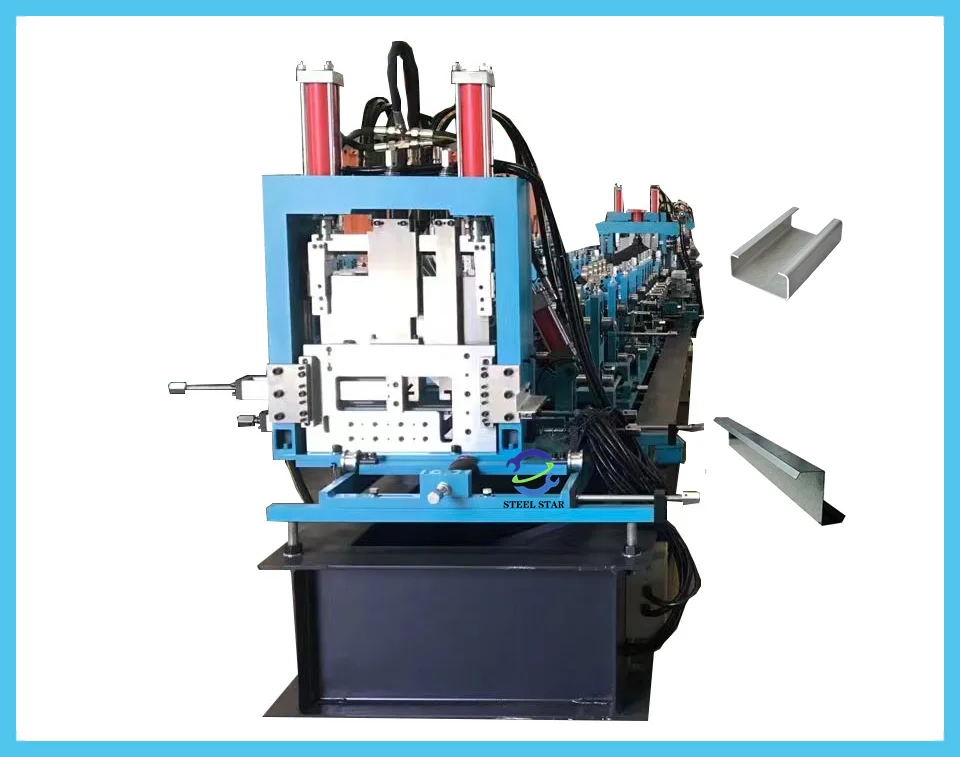

The fully automatic CZ steel roll forming machine is a kind of equipment used to produce C-shaped steel and Z-shaped steel, which is often used in the steel frame manufacturing of buildings and industrial structures. It is a cold-bending forming equipment that can realize continuous forming and cutting of steel through automatic control. The following are some of the main features of the equipment:

- High automation: Through the PLC control system, it can automatically complete the feeding, forming, cutting and other processes of steel, greatly improving production efficiency.

- Versatility: It can produce C-shaped steel and Z-shaped steel of different specifications, usually only need to adjust the mold of the machine or replace a small number of parts.

- High forming accuracy: Due to the use of roll forming technology, it can ensure the accuracy of the size of steel during the forming process and reduce material waste.

- Efficient: Fully automated operation can greatly shorten the production time and is suitable for mass production, especially in projects that require a large number of steel structures such as buildings, bridges, and scaffolding.

- Sturdy and durable: The equipment is usually made of high-strength steel to ensure the long-term stable operation of the machine.

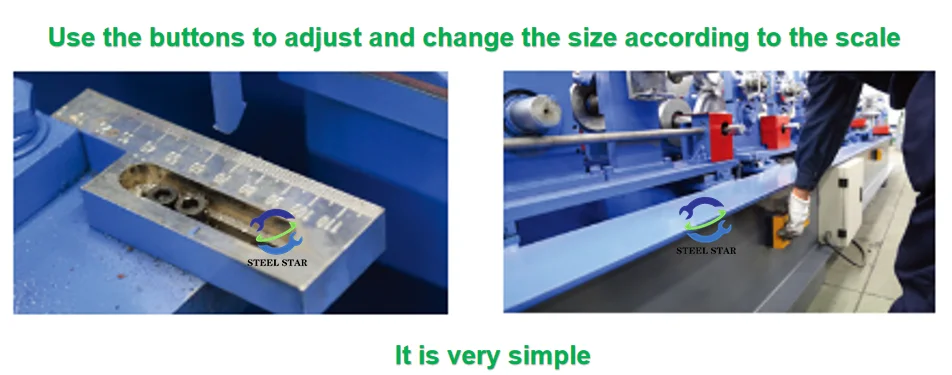

- Automatic adjustment: The equipment can adjust the length, width and bending angle of the steel according to different production requirements to meet the needs of different projects.

This machine is suitable for occasions in the construction field where large-scale production of steel structures is required, helping to improve production efficiency and reduce labor costs

The fully automatic CZ model change roll forming machine is a more advanced equipment, specially designed for efficient production of different types of C-shaped steel and Z-shaped steel, and can automatically switch specifications without manual mold change. This equipment is suitable for occasions where different steel types need to be quickly switched. The main features are as follows:

Main features:

- Fast model switching: Through the automated control system, the equipment can switch between C-shaped steel and Z-shaped steel, and can adjust the width and height of the steel according to production needs without stopping or changing molds, greatly improving production flexibility.

- Intelligent control: Using PLC programming controller and touch screen operation, parameter setting is simple, workers can directly input the required size, model, etc. through the human-machine interface, and the system will automatically adjust the equipment to produce the required specifications of steel.

- High-efficiency production: The speed of roll forming can be adjusted according to production needs, and the equipment can run continuously, minimizing the changeover time, thereby improving production efficiency, especially suitable for occasions where multiple specifications of products are required in mass production.

- High forming accuracy: The automated adjustment system ensures that the dimensional accuracy of each product is consistent, whether it is C-shaped steel or Z-shaped steel, it can maintain high-quality forming effects.

- Reduce manual intervention: The fully automatic changeover design reduces the time and labor of workers to manually adjust the equipment, and improves the automation and safety of the production line.

- Stability and durability: The equipment has a solid structure and is usually made of high-strength alloy steel. It has good wear resistance and long service life and can work stably for a long time in a high-intensity production environment.

- Multifunctional scalability: Some equipment also has other extended functions, such as punching, cutting, bending and other processes. The production line can also be customized according to different needs to meet the manufacturing needs of more steel structures.

In summary, this type of machine greatly improves production efficiency and flexibility, and is very suitable for steel structure production environments that require efficient and fast model switching.

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)