Door Frame

A door frame is an important component of a building’s structure that surrounds and supports the door. It is usually made of wood, metal, or plastic and consists of vertical and horizontal members. Door frames provide stability and security, ensuring that the door operates smoothly and remains in place. They also contribute to the overall aesthetic of a building, with different styles and finishes available to match various architectural designs.

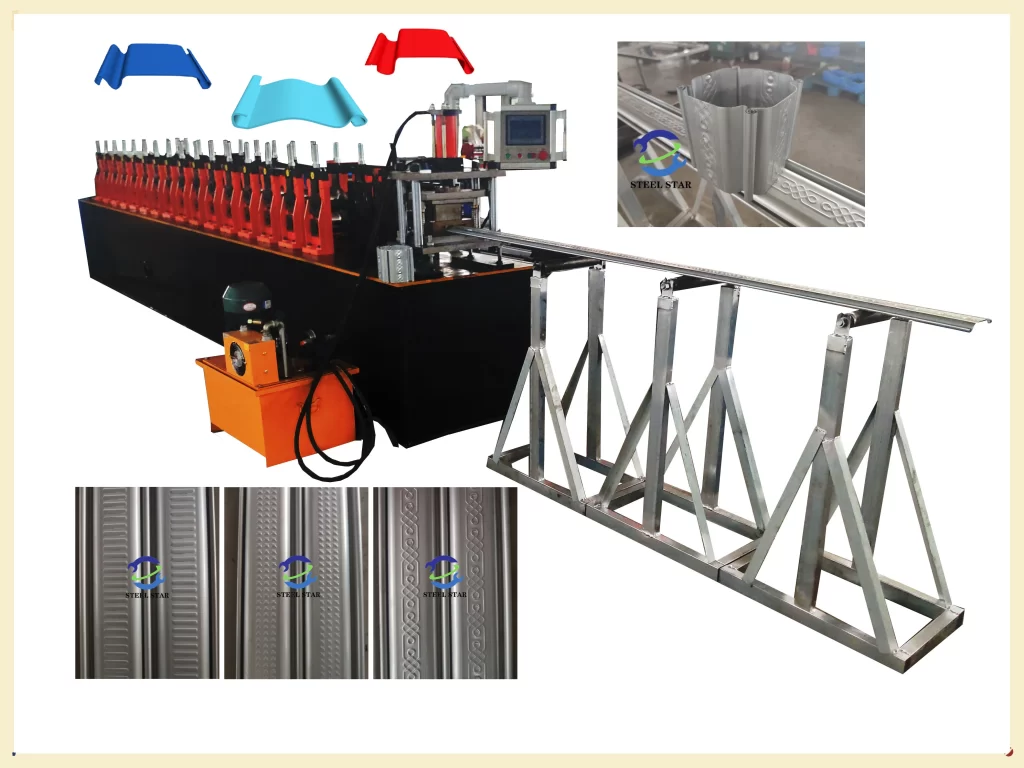

Door Frame Machine

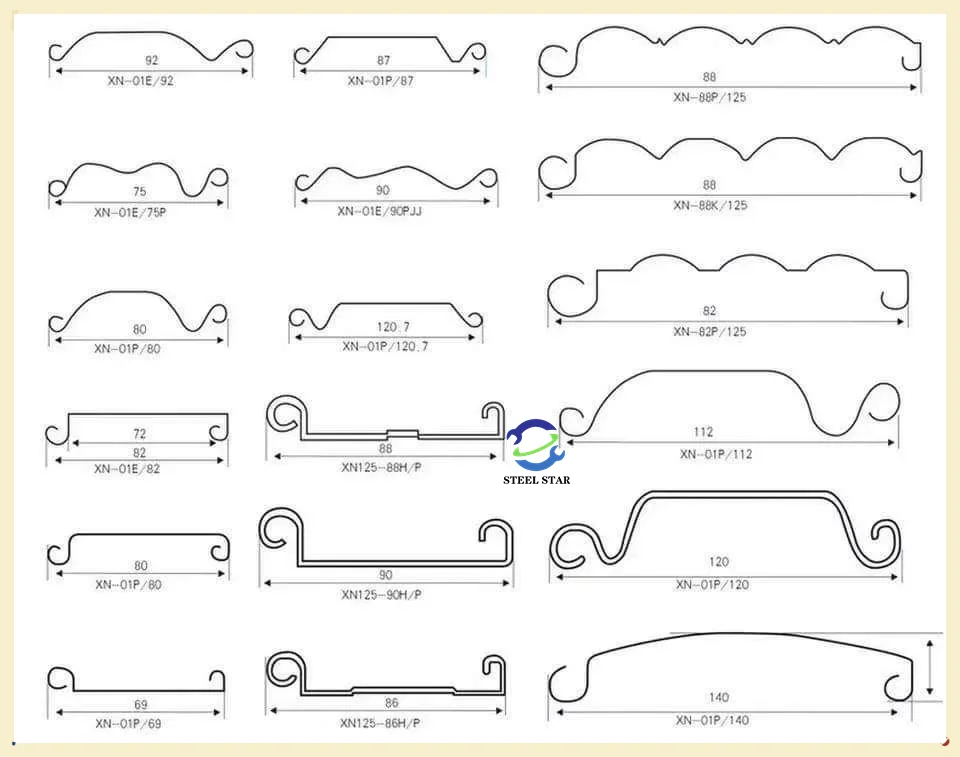

A door frame machine is a specialized piece of equipment used in the manufacturing of door frames. There are several types of door frame machines, each designed for specific manufacturing needs. A standard door frame roll forming machine is commonly used to produce traditional door frame profiles efficiently. It features a roll forming system with sets of rollers that gradually shape the raw material into the desired cross-sectional profile of a door frame. A CNC door frame machine is equipped with computer numerical control technology, offering precise and customizable manufacturing capabilities for complex and intricately designed door frames.

A Door Frame Machine is a crucial tool in the construction industry. It’s engineered to fabricate door frames with high precision. Utilizing advanced technology, it can handle various materials like metal or wood. With automated processes, it boosts production efficiency, ensuring consistent quality. From shaping to cutting, it streamlines the frame-making, meeting diverse architectural demands.

In the future construction industry, the development trend of Door Frame Machine is as follows:

Improved intelligent automation

With the development of artificial intelligence and Internet of Things technology, Door Frame Machine will have stronger autonomous learning and decision-making capabilities, can automatically adjust parameters, optimize production processes, reduce human intervention, improve production efficiency and product quality, and can also achieve remote monitoring and fault diagnosis through the network.

Increased customization demand

The personalized development of architectural design has diversified the requirements for the size, shape, material and function of door frames. Door Frame Machine needs to have higher flexibility and adjustability to meet customized production needs, quickly switch between different production modes, and manufacture door frames that meet the requirements of specific projects.

Integration with green building concepts

Driven by environmental protection policies, Door Frame Machine will pay more attention to material utilization and energy conservation, adopt environmentally friendly materials and energy-saving technologies, reduce energy consumption and pollutant emissions, and the door frames produced will also have better insulation, heat insulation, sound insulation and other properties, in line with green building standards.

Multifunctional integrated development

In order to improve production efficiency and reduce costs, Door Frame Machine may integrate multiple functions, such as cutting, welding, bending, stamping, etc., to achieve one-stop processing from raw materials to finished products, and at the same time have auxiliary functions such as automatic loading and unloading, material transmission, etc., to form a complete production line.

Closer human-machine collaboration

In the future, Door Frame Machine will not completely replace manual labor, but will realize a human-machine collaborative working mode. Humans will be responsible for complex tasks and creative work that are difficult for machines to complete, such as design, debugging, maintenance, etc., to jointly improve production efficiency and product quality.

Technological innovation promotes upgrading

Technological advances in related fields such as mechanical manufacturing and materials science will provide support for the development of Door Frame Machine. New materials and manufacturing processes can improve machine performance and life, and advanced control systems and sensor technologies can improve machine accuracy and stability.

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)