Precision in Every Opening: The Door Frame Roll Forming Machine

In the world of modern construction and architectural fabrication, efficiency, consistency, and strength are paramount. The door frame roll forming machine stands as a cornerstone technology that delivers on all three, revolutionizing the production of one of the most fundamental building components: the door frame.

What is a Door Frame Roll Forming Machine?

A door frame roll forming machine is a specialized, continuous cold-forming production line designed to transform flat coils of metal—typically galvanized steel, aluminum, or stainless steel—into precise, uniform, and high-strength door frame profiles. It employs the roll forming process, where the metal strip is progressively shaped through a series of precisely engineered roller dies until it achieves the desired complex cross-section.

These machines produce the jambs (side posts) and headers (top piece) that form the structural skeleton of door assemblies, commonly used in commercial buildings, hospitals, schools, fire-rated assemblies, and increasingly in residential applications for enhanced security and durability.

Core Components and How It Works

A standard production line integrates several key stations:

- Decoiler & Feed-In: A heavy-duty decoiler holds the master coil of pre-finished metal (often pre-painted or galvanized) and feeds it into the machine.

- Roll Forming Mill: The heart of the system. Here, a succession of paired roller dies (typically 10 to 18 stations) incrementally bends the flat strip at specific points. With each station, the profile becomes more defined, ultimately forming the complete frame shape which may include lips for drywall, stops for the door, and channels for hardware or sealing.

- Punching/Notching Unit: An integral, synchronized station that punches out precise holes for locksets, hinges, and anchor bolts, or creates corner notches for perfect 45-degree or 90-degree miters. This is often a servo-driven flying unit that operates in sync with the moving material.

- Cut-Off System: A high-speed, hydraulic or servo-controlled flying cut shears the continuously formed profile to the exact required length without stopping the production line.

- Control System: A centralized PLC (Programmable Logic Controller) and HMI (Human-Machine Interface) panel allow operators to input dimensions, select profiles, and monitor the entire process, ensuring repeatable accuracy.

Key Technical Advantages

- Unmatched Consistency & Precision: Every meter of produced frame has an identical cross-section and hole pattern, critical for mass production, easy installation, and reliable performance of doors and hardware.

- High Strength & Material Efficiency: The cold-forming process work-hardens the metal, and the designed profile geometry creates a structurally rigid component from relatively thin gauge material, optimizing strength-to-weight ratio.

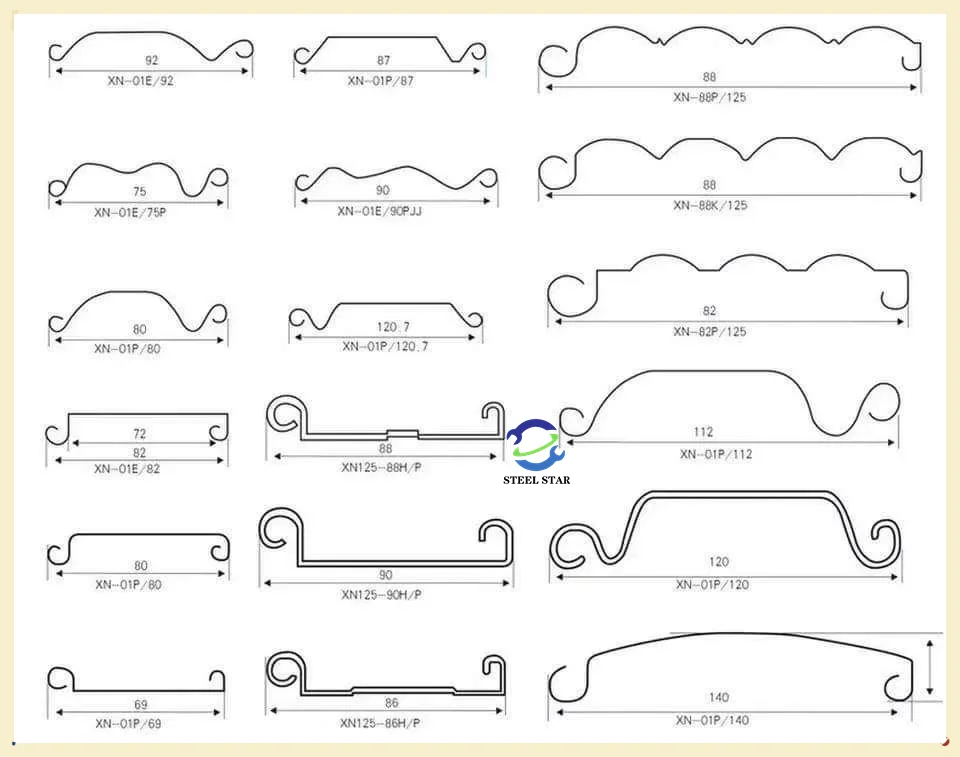

- Seamless Lengths & Flexibility: The machine can produce frames in continuous, single-piece lengths limited only by coil weight and handling logistics, eliminating weak joints. Quick-change roll systems allow one machine to produce multiple frame profiles.

- Superior Production Speed & Low Waste: Operating at speeds of 15-45 meters per minute, it far outpaces traditional fabrication methods like brake pressing or welding. The integrated punching and precision cutting minimize material scrap.

- Excellent Surface Finish: Since it forms pre-finished coil stock, the final product has a pristine, unmarked surface, unlike processes that might scratch or damage post-applied coatings.

Applications and Output Profiles

These machines are versatile, producing frames for:

- Commercial Steel Door Frames: Standard knock-down (KD) frames for interior and exterior applications.

- Fire-Rated and Blast-Resistant Frames: Requiring tight tolerances and specific profiles to meet stringent certification standards.

- Sliding Door and Storefront Systems: For aluminum glazing systems.

- Custom Architectural Openings: Including frames for special hardware integrations or unique wall conditions.

Investment and Market Considerations

The price of a door frame roll forming machine varies significantly based on automation level, speed, and complexity. Key cost drivers include:

- Level of Automation (manual feeding vs. auto-coil change)

- Punching Complexity (number of servo axes, tooling sets)

- Production Speed & Precision

- Brand Origin and Component Quality (e.g., European/Japanese servo systems vs. local equivalents)

The door frame roll forming machine is more than just a fabricator; it is an enabler of modern, efficient construction. By delivering unparalleled precision at high volume, it allows manufacturers to meet the growing demand for durable, reliable, and cost-effective door systems. For any serious player in the metal door frame industry, investing in this technology is not merely an upgrade—it is a strategic move to ensure competitiveness, quality, and the ability to shape the very openings through which we move. It stands as a testament to how precision engineering builds the foundation for secure and functional architecture.

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)