Door Roll Forming Machine: Precision Engineered for Modern Entry Systems

Introduction: Defining the Gateway of Modern Construction

In the evolving landscape of architectural design and building technology, doors represent more than mere physical barriers—they are integral components that define security, energy efficiency, and aesthetic appeal. At the heart of producing these critical building elements lies the Door Roll Forming Machine—a sophisticated piece of industrial equipment that transforms flat metal coils into precise, high-strength door frame and panel profiles with remarkable efficiency and consistency.

Core Function and Working Principle

A Door Roll Forming Machine operates on the principle of progressive cold-forming, where pre-coated metal coils are continuously shaped through a series of precision-engineered roller dies. Unlike traditional fabrication methods that involve welding and manual assembly, this automated process creates seamless, uniform profiles in a single continuous operation.

The machine’s workflow follows this systematic sequence:

- Coil Loading and Feeding: A decoiler holds the metal coil (typically galvanized steel, aluminum, or pre-painted materials) and feeds it into the leveling system

- Material Preparation: The metal strip passes through leveling rollers to eliminate any inherent curvature or imperfections

- Progressive Forming: The flat strip enters a series of roll-forming stations, each performing incremental bends to gradually achieve the final cross-sectional profile

- Accessory Integration: Optional stations can add reinforcement ribs, locking mechanisms, or special grooves during the forming process

- Precision Cutting: A synchronized flying cut system sections the continuous profile into predetermined lengths without stopping production

- Output Handling: Automated stackers organize finished components for packaging and shipment

Technical Specifications and Key Components

Modern door roll forming machines incorporate several critical subsystems:

1. Decoiler System

- Hydraulic or motor-driven mandrels for heavy coil handling

- Automatic edge guidance for material alignment

- Tension control mechanisms for consistent feeding

2. Roll-Forming Station

- Multiple forming stands (typically 10-25 stations)

- High-carbon chromium steel rollers with precision bearings

- Quick-change tooling systems for profile versatility

3. Control System

- PLC-based automation with touch-screen HMI

- Servo-driven positioning for cut-length accuracy

- Real-time monitoring and diagnostics

4. Cutting Mechanism

- Hydraulic or servo-electric flying cut-off

- Dual-cylinder systems for vibration-free operation

- Programmable cutting patterns for complex assemblies

5. Auxiliary Systems

- In-line punching and notching stations

- Embossing units for decorative patterns

- Automatic lubrication and cooling systems

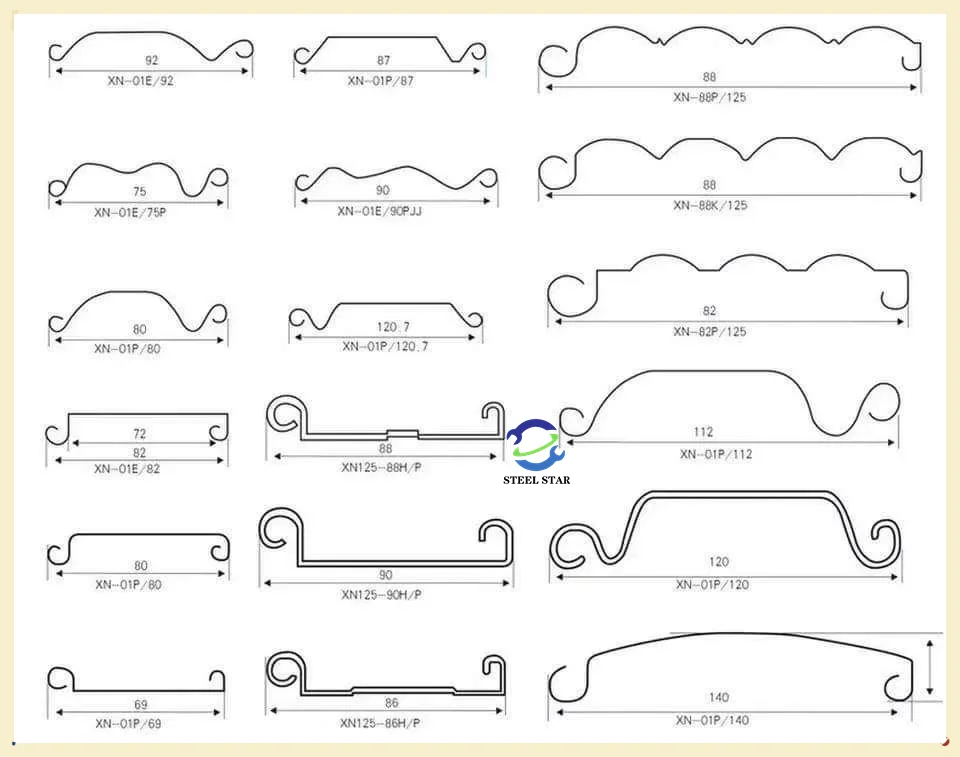

Profile Versatility and Applications

These machines produce various door-related components:

Door Frame Profiles:

- Steel door jambs and thresholds

- Reinforced frame sections for security doors

- Thermal-break profiles for energy-efficient designs

Door Panel Components:

- Flush door skin panels

- Panel-and-rail system components

- Decorative embossed patterns

Specialized Applications:

- Fire-rated door frames

- Blast-resistant door components

- Cleanroom and specialized industrial doors

Advanced Technological Features

Modern machines incorporate several sophisticated technologies:

1. Precision Control Systems

- Closed-loop servo control for dimensional accuracy

- Automatic thickness compensation for material variations

- Digital encoder feedback for speed synchronization

2. Quality Assurance Integration

- Laser measurement systems for real-time profile verification

- Vision inspection for surface quality monitoring

- Automatic defect detection and marking

3. Production Optimization

- Predictive maintenance scheduling

- Energy-efficient drive systems

- Material utilization optimization software

4. Smart Manufacturing Capabilities

- IoT connectivity for remote monitoring

- Production data analytics

- Integration with factory management systems

Industry Impact and Benefits

The adoption of door roll forming technology has revolutionized the door manufacturing industry:

Economic Advantages:

- Production speeds of 20-60 meters per minute

- Material utilization rates exceeding 98%

- Labor cost reduction through automation

- Minimal scrap generation

Quality Improvements:

- Consistent dimensional accuracy (±0.2mm tolerance)

- Superior surface finish preservation

- Enhanced structural integrity through work-hardening

- Repeatable quality across production runs

Design Flexibility:

- Quick changeover between profiles (typically under 30 minutes)

- Custom profile development capabilities

- Integration of multiple functions in single pass

Environmental Benefits:

- Reduced energy consumption compared to welding

- Elimination of finishing processes

- Recyclable material optimization

Case Study: Evolution in Action

Consider the transformation in security door manufacturing:

Traditional Method:

- Multiple welding operations

- Manual assembly

- Inconsistent quality

- High labor intensity

- Significant material waste

Roll Forming Solution:

- Single continuous process

- Automated production

- Consistent high quality

- Reduced labor requirements

- Minimal material waste

Future Trends and Developments

The door roll forming industry continues to evolve with several emerging trends:

1. Intelligent Manufacturing

- Artificial intelligence for process optimization

- Digital twin technology for virtual simulation

- Advanced predictive analytics

2. Material Innovation

- Advanced high-strength alloys

- Composite material processing

- Sustainable and recycled materials

3. System Integration

- Complete door manufacturing cells

- Robotic handling and assembly

- End-to-end automated solutions

4. Customization Capabilities

- Small-batch economic production

- Rapid prototyping systems

- Design-to-production digital workflows

The Door Roll Forming Machine represents more than just production equipment—it embodies the convergence of precision engineering, material science, and smart manufacturing. As architectural demands evolve toward higher performance standards, greater customization, and sustainable practices, these machines will continue to advance, offering:

- Enhanced Precision: Tighter tolerances and superior consistency

- Greater Flexibility: Expanded material and profile capabilities

- Improved Sustainability: Reduced waste and energy consumption

- Increased Intelligence: Self-optimizing production systems

For manufacturers seeking competitive advantage in the global door market, investing in advanced roll forming technology is not merely an option—it’s a strategic imperative. These machines enable the production of doors that meet the highest standards of security, energy efficiency, and design excellence while maintaining economic viability in an increasingly competitive marketplace.

The continuous innovation in door roll forming technology ensures that the industry will remain at the forefront of building component manufacturing, creating products that protect, insulate, and enhance the spaces where we live and work. As we look to the future, these machines will undoubtedly play a crucial role in shaping the next generation of architectural entry systems—making our buildings safer, more efficient, and more beautiful, one precisely formed profile at a time.

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)