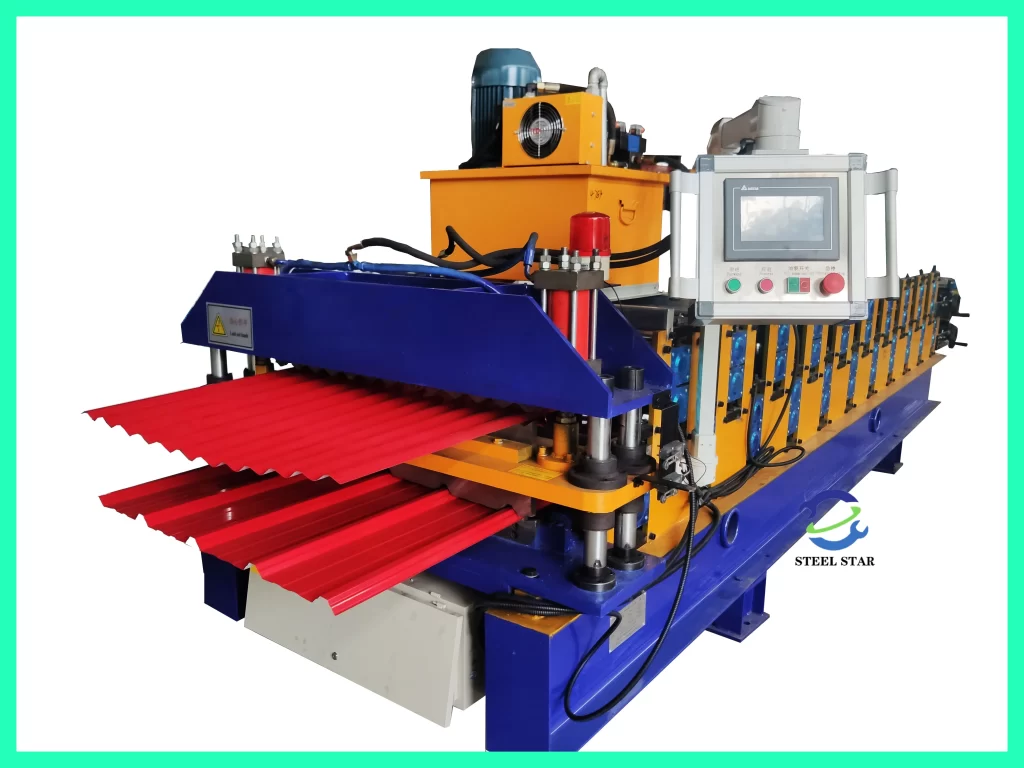

Double Layer Roll Forming Machine: Engineering Compound Strength and Efficiency

In the world of metal fabrication for architectural, automotive, and industrial applications, conventional single-layer roll forming machines have long been the standard for producing uniform profiles. However, as design requirements evolve toward greater structural complexity, insulation efficiency, and aesthetic versatility, a more advanced solution has emerged: the Double Layer Roll Forming Machine.

This sophisticated system represents a significant technological leap, capable of simultaneously forming two separate metal layers—often with different materials, coatings, or geometries—and bonding them into a single, composite panel in a continuous, automated process. This article explores the design, operation, applications, and advantages of this innovative machinery.

1. Core Concept and Working Principle

A double layer roll forming machine integrates two independent roll forming lines that converge into a single bonding and finishing section.

Process Flow:

- Dual Decoiling: Two separate coils of metal (e.g., pre-painted galvanized steel, aluminum, stainless steel) are loaded onto decoilers. These coils can be of identical or different materials, thicknesses, and coatings.

- Parallel Forming: Each metal strip is fed into its own dedicated roll forming mill. Here, they are individually shaped through a series of roll stations into two distinct profiles. These profiles are engineered to fit together perfectly.

- Core Material Insertion (Optional but Common): In applications requiring insulation, a continuous strip of core material—such as expanded polystyrene (EPS), rock wool, polyurethane (PUR/PIR) foam, or a thermoplastic core—is automatically introduced between the two formed metal layers at the convergence point.

- Bonding and Lamination: The critical stage where the two layers are united. Depending on the product, bonding is achieved through:

- Adhesive Application: A hot-melt or structural adhesive is applied to the inner surfaces before pressing.

- Thermal Bonding (for foam cores): The pre-heated metal layers activate the foam’s adhesive properties or are bonded via a heated lamination process.

- Mechanical Lock Seaming: The profiles themselves are designed to mechanically interlock.

- Calibration & Curing: The composite sandwich passes through a series of pressure rollers or a heated chamber to ensure uniform bond strength and dimensional stability.

- Cut-to-Length: A high-precision, synchronized flying cut-off system cleanly severs the continuous composite panel to the required length.

- Output and Stacking: Finished panels are automatically stacked and bundled.

2. Key Technical Components and Innovations

- Synchronized Dual Forming Lines: The heart of the machine. Two fully independent, servo-driven roll forming mills must operate with perfect synchronization to ensure the two profiles align flawlessly at the bonding point. Advanced PLC control is non-negotiable.

- Precision Core Feeder: For insulated panels, this system accurately meters and positions the insulating core material, adjusting for compression and expansion.

- Laminating/Bonding Unit: This can be a heated platen press, a series of nip rollers with adhesive applicators, or a high-frequency welding unit for specific thermoplastics. It applies controlled pressure and temperature.

- Advanced Control System: A central industrial computer (PLC with HMI) orchestrates the speed, alignment, temperature, pressure, and cutting of both lines as a single entity. It stores recipes for different panel types.

3. Primary Applications and Product Output

The machine is designed to manufacture high-value composite panels:

- Insulated Sandwich Panels: The most common application. Produces roof and wall panels with a structural insulating core (PUR, EPS, Mineral Wool) between two metal skins. These panels provide excellent thermal efficiency (low U-values) and structural integrity for cold storage, warehouses, and commercial buildings.

- Acoustic Panels: Creates panels designed for sound dampening, using a specialized acoustic core.

- Structural Composite Panels: Produces panels where the double-layer metal design itself provides enhanced rigidity and span capability, often with an air gap instead of a solid core.

- Aesthetic/Architectural Panels: Allows for combinations of different metals or colors on the exterior and interior surfaces, meeting specific design requirements.

4. Advantages over Single-Layer Machines

- Integrated Production: Combines forming, insulation, and lamination into one uninterrupted line, eliminating multiple handling and production steps.

- Superior Product Performance: Delivers panels with exceptional thermal insulation, acoustic properties, and structural strength in a single, lightweight element.

- Aesthetic and Functional Versatility: Facilitates the creation of custom panels with different interior and exterior finishes.

- Construction Speed: The finished panels are “ready-to-install,” dramatically reducing on-site labor and assembly time for building envelopes.

- Consistent Quality: Automated control ensures uniform bonding and thickness across the entire panel, minimizing defects.

5. Challenges and Considerations

- High Capital Investment: The complexity of dual-line synchronization and bonding technology makes these machines a significant investment.

- Technical Complexity: Operation and maintenance require highly skilled technicians with expertise in roll forming, adhesion chemistry, and thermal processes.

- Material Handling: Managing two coils and a core material simultaneously adds logistical complexity to raw material supply.

The double layer roll forming machine is a transformative technology at the intersection of advanced manufacturing and building science. It moves beyond simple profile shaping to become a producer of complete, high-performance building systems. By seamlessly integrating multiple materials into a cohesive unit, it addresses the core demands of modern construction: energy efficiency, build speed, and design flexibility.

As global building codes continue to emphasize sustainability and energy conservation, the demand for high-performance insulated panels will only grow. The double layer roll forming machine stands as the essential industrial apparatus meeting this demand, fabricating the intelligent, composite skins that define the efficient buildings of the 21st century. It is not just a machine that forms metal; it is a machine that builds better environments.

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)