The Downpipe Forming Machine: Precision in Water Management

In the essential network of a building’s rainwater management system, the downpipe (or downspout) serves as the critical vertical conduit, directing water efficiently from roof gutters to drainage or collection points. The downpipe forming machine is the specialized industrial equipment that manufactures these vital components with high precision, consistency, and efficiency. This technology has revolutionized the production of downpipes, moving it from manual fabrication to automated, high-speed manufacturing.

What is a Downpipe Forming Machine?

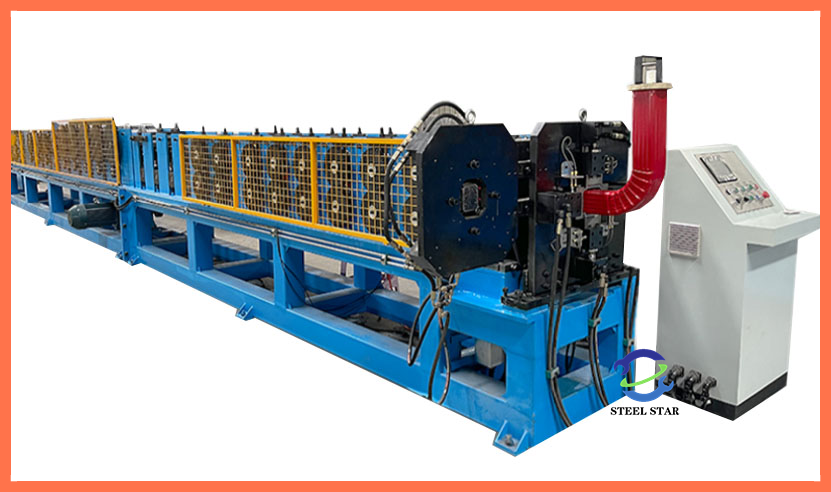

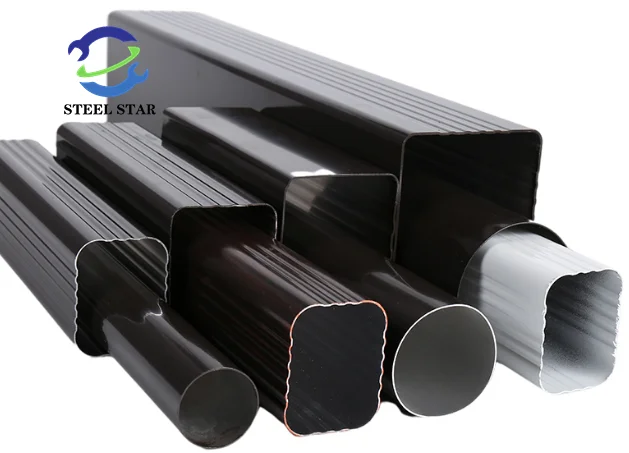

A downpipe forming machine is a type of roll forming machine specifically engineered to produce standardized downpipe profiles from coiled metal strips—typically pre-coated galvanized steel, aluminum, or copper. Through a continuous cold-forming process, it transforms flat metal into seamless, uniform downpipe sections of precise dimensions and shapes, such as round, rectangular, or corrugated profiles.

The core principle involves progressively shaping the metal strip through a series of precisely contoured roller dies. Each station performs a minor bend until the final closed-welded or lock-seam profile is achieved in a single, uninterrupted operation.

Core Components and Operational Process

A standard downpipe production line integrates several key stations into a synchronized system:

- Decoiler & Feed System: A heavy-duty decoiler holds the master coil of pre-finished metal and feeds it smoothly into the machine. An integrated straightening device ensures the strip is flat before forming.

- Pre-Punching/Notching Unit (Optional): For downpipes requiring outlet holes for branch connections or specific fixing points, a servo-driven punching station can be integrated to add these features inline before the forming process.

- Roll Forming Mill: The heart of the machine. A sequence of roller dies (typically 10-18 stations) gradually bends the metal strip. For a round downpipe, the process shapes the strip from flat to a closed cylinder. A critical final station forms the longitudinal seam—either a lock seam (where the edges interlock) or, in more advanced lines, prepares the edges for welding.

- Seam Welding/Closing Unit: For high-strength, leak-proof round pipes, an inline TIG (Tungsten Inert Gas) or HF (High-Frequency) welding unit immediately welds the longitudinal seam as the pipe emerges from the former. This creates a perfectly sealed, smooth interior crucial for optimal water flow and corrosion resistance.

- Sizing & Calibration Section: The welded or locked pipe passes through a series of sizing rolls or dies that ensure perfect roundness/rectangularity and exact final diameter, correcting any minor deformation from the welding heat.

- Cut-Off System: A high-speed, servo-controlled flying saw or cutter cleanly shears the continuous pipe to pre-set lengths (e.g., standard 2m, 3m, or 6m lengths) without stopping production.

- Control System: A central PLC (Programmable Logic Controller) allows operators to input parameters like pipe diameter, length, and hole patterns, ensuring full automation and repeatability.

Key Advantages and Technical Features

- Seamless, High-Strength Output: The continuous production of long, single-length pipes eliminates intermediate joints, which are potential leak points. Inline welding creates a homogeneous, robust product.

- Superior Precision and Consistency: Every section has identical dimensions and geometry, ensuring perfect fit and ease of installation on-site. Diameter tolerances can be held within ±0.5mm.

- High Production Speed and Efficiency: Modern lines can produce pipes at speeds of 15-50 meters per minute, far exceeding manual or semi-automatic methods. Material waste is minimized.

- Material and Profile Versatility: Machines can be configured for different materials (steel, aluminum) and profiles (round from 75mm to 150mm, rectangular, etc.) with quick-change tooling systems.

- Excellent Surface Finish: Since the machine forms pre-painted or coated coil stock, the final product has a pristine, unmarred finish, enhancing durability and aesthetics.

Applications and Market Significance

Downpipes formed by these machines are integral to:

- Commercial and Residential Construction: As part of complete rainwater systems.

- Industrial Buildings: Requiring large-diameter pipes for high-volume drainage.

- Renovation and Historical Replication: Machines can be tooled to produce period-specific profiles for restoration projects.

It is justified by the superior quality, production scale, and competitive edge it provides to manufacturers and metal roofing contractors.

The downpipe forming machine exemplifies how targeted engineering elevates a simple functional component into a high-performance, precision-engineered product. By ensuring leak-proof integrity, hydraulic efficiency, and long-term durability, it plays a fundamental role in protecting building envelopes from water damage. For manufacturers, it transforms downpipe production from a labor-intensive task into a streamlined, profitable, and quality-controlled core competency, solidifying its status as an indispensable asset in modern metal fabrication and sustainable construction practices.

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)