The Downpipe Machine: Engineering Precision for Water Management

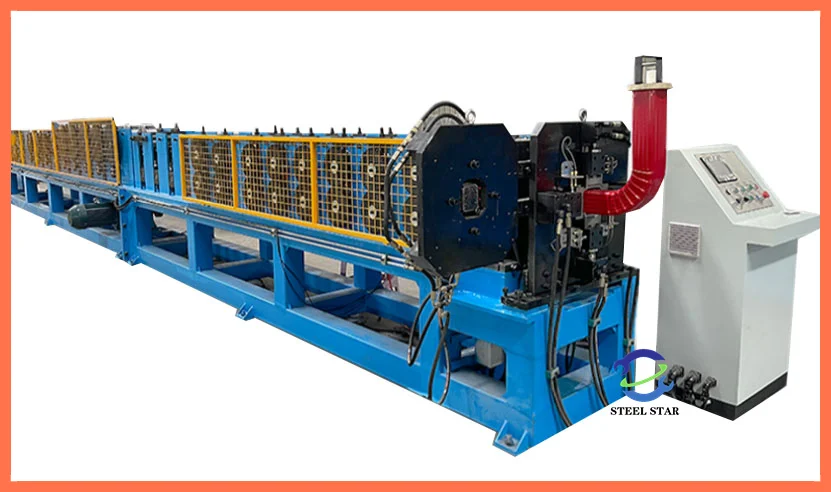

In the architectural ecosystem of a building, the downpipe (or downspout) is a critical yet often overlooked component, responsible for efficiently channeling rainwater from the roof to the drainage system. The machine that manufactures these essential elements—the Downpipe Machine—is a specialized piece of industrial engineering that combines roll-forming technology with precision fabrication to produce durable, consistent, and cost-effective gutter systems.

Core Function and Output

A Downpipe Machine is a type of cold roll-forming machine specifically designed to fabricate the vertical pipes and associated components (such as elbows, offsets, and shoes) that constitute a building’s rainwater drainage system. Starting from coiled steel, aluminum, or copper sheet, the machine forms, shapes, and cuts the metal into complete downpipe sections with consistent cross-sections, typically rectangular, round, or corrugated profiles.

Key Components and Operational Process

A standard downpipe production line integrates several sequential stations:

- Decoiler & Straightener: Holds and feeds the master metal coil into the line, ensuring flat, consistent material entry.

- Pre-Punching/Notching Unit (Optional): For pipes requiring integrated attachment holes or downpipe outlet openings, a CNC punching station performs these operations prior to forming.

- Roll Forming Mill: The heart of the machine. A series of precision-engineered roller dies progressively bend the flat metal strip into the desired closed pipe profile. The number of stands determines the smoothness and accuracy of the final shape.

- Seaming/Welding Station: For lock-seam or welded pipes, this critical unit joins the longitudinal edges of the formed profile. Methods include:

- Lock-Forming: The edges are mechanically interlocked without filler material, common for aluminum and steel.

- High-Frequency (HF) Welding: Creates a solid-state welded seam for steel pipes, resulting in a exceptionally strong, leak-proof joint.

- Cut-Off System: A flying cut-off saw or hydraulic shear cleanly cuts the continuously produced pipe to pre-set lengths without stopping the line.

- Post-Forming & Discharge: May include sizing stations, embossing units, or automatic stacking systems for finished pipes.

Types of Downpipe Machines

Machines are often categorized by their primary output:

- Rectangular/Round Pipe Machines: Produce standard downpipe profiles.

- Corrugated Pipe Machines: Create pipes with ribbed surfaces for added rigidity and visual interest.

- Integrated Line Machines: Combine downpipe production with the fabrication of matching gutters, elbows, and end caps for a complete system output.

- Material-Specific Configurations: Optimized for the forming characteristics of aluminum (softer, requires precise tooling), galvanized steel (robust, often welded), or pre-painted materials (requires surface-protective tooling).

Technical Advantages and Industry Impact

- High Production Efficiency: Enables continuous, automated manufacturing at speeds of 15-50 meters per minute, drastically outpacing manual fabrication.

- Superior Product Consistency: Every pipe segment has identical dimensions and seam integrity, ensuring reliable on-site assembly and a uniform appearance.

- Material Optimization & Strength: The cold-forming process can increase material strength, while precision cutting minimizes waste. HF welding produces seams stronger than the base metal.

- Design Flexibility: Quick-change tooling allows a single line to produce multiple pipe sizes, profiles, and lengths, responding agilely to market demands.

- Durability & Weather Resistance: Machine-produced pipes offer precise, consistent seams that are crucial for long-term leak prevention and corrosion resistance.

Selection Considerations for Manufacturers

Investing in a downpipe line requires evaluating:

- Target Profile and Material: The desired final shape (e.g., 75x50mm rectangular, 100mm round) and metal type (GI, GL, Alu-Zinc, Aluminum).

- Production Volume and Speed: Required output capacity (tons/shift).

- Seam Technology Choice: Lock-seam for versatility vs. HF weld for maximum strength on steel.

- Automation Level: Degree of auto-stacking, packing, and CNC control integration.

- Tooling Quality and Support: Precision-hardened roller dies and reliable technical service are paramount for longevity.

The Downpipe Machine represents a specialized fusion of mechanical design and practical hydraulics engineering. By automating the production of these vital components, it ensures the construction industry has access to high-quality, reliable, and efficient rainwater management systems. As building codes emphasize sustainable water handling and architects seek aesthetically pleasing profiles, the technology within these machines continues to evolve. They stand as a testament to how industrial manufacturing underpins even the most fundamental elements of functional and durable architecture, quietly safeguarding structures from the relentless challenge of water.

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)