Beneath the eaves of nearly every modern structure, a critical yet often overlooked system works tirelessly: the rainwater drainage network. At the heart of manufacturing the key components of this system—the downspout pipes and gutters—lies a marvel of industrial automation: the Downspout Pipe Roll Forming Machine. This sophisticated equipment transforms raw metal coils into precisely engineered profiles with speed, consistency, and efficiency that define modern metal fabrication.

Core Function and Principle

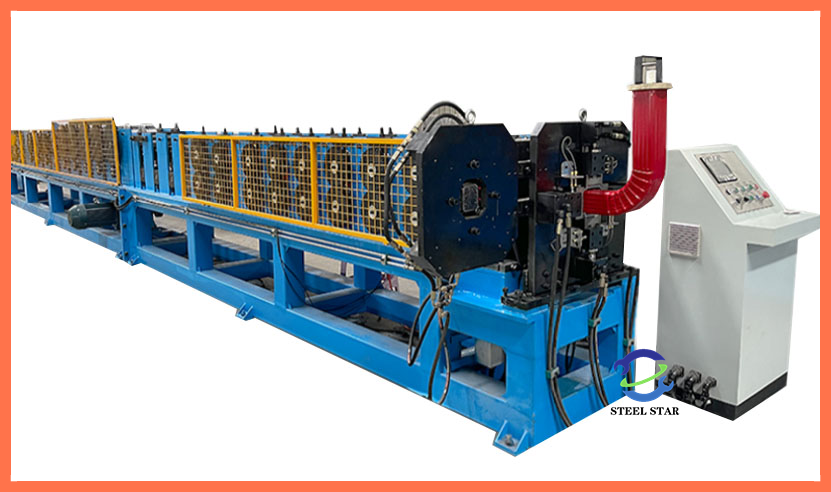

A downspout pipe roll forming machine is a continuous, cold-forming system. Its primary function is to progressively shape a flat sheet or coil of metal (typically galvanized steel, aluminum, or pre-painted coil) into a uniform, long-length downspout pipe or gutter profile through a series of paired rotary dies.

The fundamental process is elegant in its sequential precision:

- Uncoiling: A heavy metal coil is mounted on a decoiler, which feeds the material into the machine.

- Leveling: The metal passes through a precision leveler to remove any coil memory or curvature, ensuring a perfectly flat strip.

- Pre-Punching/Notching (Optional): An integrated servo-driven punching station can add precise downspout outlet holes, connector slots, or decorative embossing before forming.

- The Roll Forming Mill: This is the machine’s core. The flat strip passes through a series of tandem roll stands (from 10 to 20+ stations), each equipped with a set of hardened steel rollers. Each successive station incrementally bends the metal by a few degrees, gradually forming the final closed or open profile without removing material. This cold-working process also increases the strength of the final product.

- Cutting to Length: At the end of the line, a high-precision flying cut-off system—synchronized with the moving profile—cuts the continuous formed pipe into predetermined lengths without stopping production.

- Run-out Table & Stacking: The finished downspout pipes are conveyed and automatically stacked for bundling and shipment.

Key Components and Technological Features

- The Decoiler & Entry Guide: Ensures smooth, tension-controlled feeding of the metal coil.

- Servo-Driven Punching Unit: Allows for programmable, on-the-fly hole punching with extreme accuracy, enabling customization without secondary operations.

- Precision Roll Forming Stations: The custom-designed, carbide-tooled rollers are the heart of the machine, dictating the final profile’s shape, tolerances, and surface quality.

- PLC Control System: The central brain. It synchronizes all motions—from feeding and punching speed to cut-off length—ensuring consistency and allowing for quick changeovers between different downspout sizes or styles (e.g., rectangular, round, K-style gutter).

- High-Frequency Welding (for locked-seam pipes): Some advanced lines incorporate a welding unit within the forming mill to create a continuous, sealed seam for watertight downspout pipes.

The Competitive Advantages: Why Roll Forming?

Compared to traditional fabrication methods like press braking or sectional forming, the roll forming process offers transformative benefits:

- High-Speed, Continuous Production: Capable of producing 30-100 meters per minute, it is vastly more efficient for large-volume orders.

- Exceptional Consistency & Quality: Every meter of product is identical, with precise dimensions and repeatable geometry crucial for leak-proof field installation.

- Material Efficiency: Virtually no scrap is generated aside from the initial coil tail, maximizing material yield.

- Flexibility: Quick tooling changes allow a single machine to produce a range of profiles for different architectural styles and regional standards.

- Strength: The work-hardening effect of cold-forming creates a structurally superior product.

Applications and End-Product Diversity

These machines are engineered to produce the essential components of residential, commercial, and industrial rainwater systems:

- Rectangular and Round Downspout Pipes: In various standard sizes (e.g., 2″x3″, 3″x4″, 4″ round).

- Gutter Profiles: Such as K-style, half-round, or box gutters.

- Accessories: Including connector sleeves, offsets, and trim pieces.

The Evolution and Future Trends

The modern downspout roll forming machine is increasingly intelligent and connected. Future trends point toward:

- Increased Automation: Integration with robotic arms for automatic tool changeovers and finished product handling.

- IoT Integration: Machines equipped with sensors for predictive maintenance, monitoring roll wear, and tracking production data in real-time for optimal factory management.

- Sustainability Focus: Designs optimized to handle recycled-content metals and newer, lighter, more durable materials like zinc-aluminum alloys.

The downspout pipe roll forming machine is far more than a simple metal bender. It is a highly synchronized, precision-engineered system that sits at the intersection of mechanical engineering, materials science, and digital control. By enabling the fast, cost-effective, and reliable production of vital building components, this technology supports global construction and infrastructure development. It ensures that the unassuming downspouts guarding our buildings are products of relentless precision, channeling the elements away efficiently and reliably for decades—a silent testament to the power of advanced manufacturing.

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)