Floor Deck Machines and Steel Deck Machines are specialized industrial machines designed to produce metal decking profiles used in construction. These decks serve as structural platforms for flooring and roofing, offering strength, durability, and a base for concrete slabs or roofing systems. Here’s a closer look at each machine type and their applications.

1. Floor Deck Roll Forming Machine

A Floor Deck Roll Forming Machine produces metal deck panels specifically used as a structural base for concrete floors in multi-story buildings. These deck profiles provide a solid platform and reinforcement, improving load-bearing capacity and enhancing the overall floor strength.

Key Features:

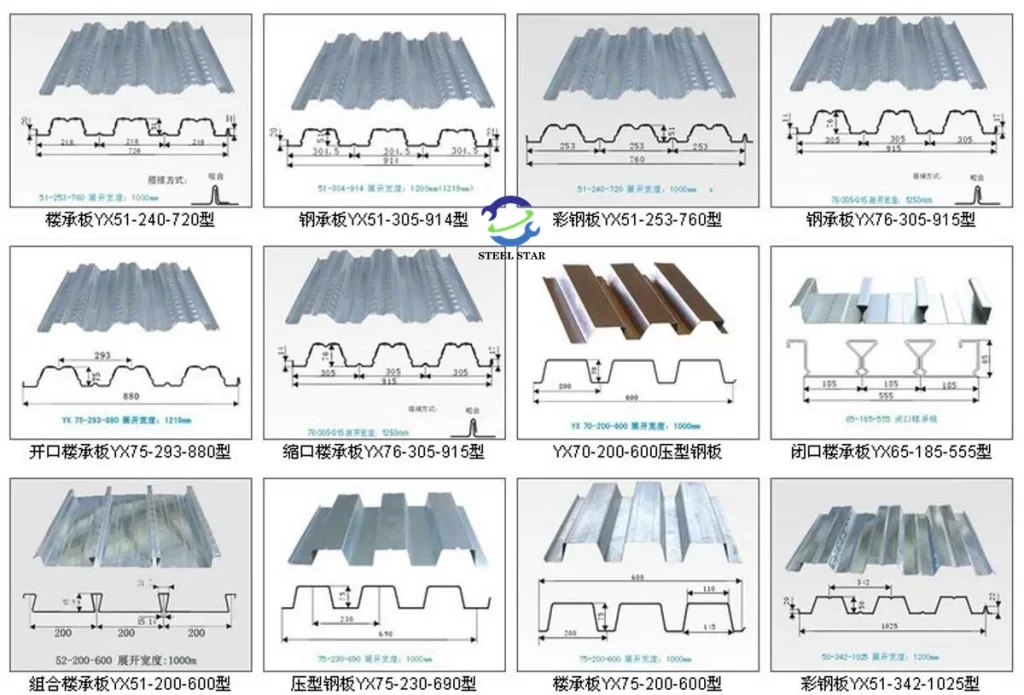

- Profile Design: Floor decking profiles often have trapezoidal or ribbed shapes with high load-bearing capabilities. They are engineered to interlock and form a stable base for concrete.

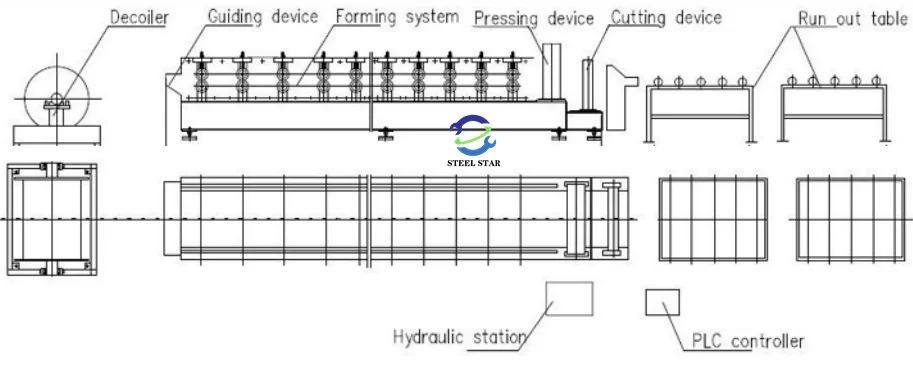

- Heavy-Duty Rollers: Equipped with robust rollers to shape thicker steel or galvanized metal sheets, which provide the necessary strength for floor decking.

- Automatic Cutting System: Includes a high-precision cutting system, typically hydraulic, to cut panels to custom lengths.

- Advanced Control System: Modern floor deck roll forming machines use PLC or CNC systems for automated production, ensuring profile consistency, length accuracy, and high output speeds.

Applications:

- Commercial and Industrial Buildings: Used in high-rise buildings, factories, warehouses, and parking garages to create floors with high load capacities.

- Residential Construction: Sometimes used in apartment complexes and other multi-story residential projects.

- Composite Decking: Works with concrete to form a composite floor, creating a single, solid structure with increased strength.

2. Steel Deck Roll Forming Machine

A Steel Deck Roll Forming Machine is similar but often more versatile, producing steel deck profiles used for both flooring and roofing applications. These steel decks serve as structural reinforcement for floors and as waterproof, durable bases for roofing systems.

Key Features:

- Versatile Profile Production: These machines can produce a variety of profiles, such as floor decks and roof decks, depending on the industry needs. The profiles typically include ribs or corrugated patterns that increase load-bearing capacity.

- Material Flexibility: Works with various types of metal, such as galvanized steel, stainless steel, or aluminum, to meet different durability, weight, and corrosion resistance requirements.

- Interlocking Design: Profiles created have interlocking features to form seamless decks, adding stability and ease during installation.

- High-Speed Production: Steel deck roll forming machines are designed for high-speed, continuous production to meet large-scale demands in commercial and industrial construction.

Applications:

- Floor and Roof Construction: Provides a durable base for floors or roofs, suitable for multi-story buildings, warehouses, factories, and large commercial structures.

- Composite Floor Decks: When combined with concrete, steel decks become a composite structure, enhancing structural integrity for large spans.

- Roofing Support: Steel decks can be used as the base layer for roofing, providing weather-resistant, fire-resistant, and long-lasting roofing solutions.

Key Differences Between Floor Deck and Steel Deck Roll Forming Machines

- Application Focus: Floor deck machines are specifically for concrete flooring systems, whereas steel deck machines are more versatile, creating profiles for both floors and roofs.

- Material Thickness: Floor deck machines typically handle thicker steel to support concrete loads, while steel deck machines may work with a broader range of material thicknesses.

- Profile Complexity: Floor deck profiles are often more complex and high-strength, while steel deck profiles for roofing can be lighter and focus on coverage and weatherproofing.

Advantages of Floor Deck and Steel Deck Roll Forming Machines

- Structural Integrity: These machines produce profiles that strengthen the overall structure, whether in flooring or roofing applications.

- Durability and Safety: Steel and concrete composite decks offer fire resistance, long-lasting durability, and stability under high loads.

- High Production Efficiency: Continuous roll forming ensures consistent quality and high output, making it feasible for large construction projects.

- Cost-Effective Construction: Using roll-formed deck panels speeds up construction timelines and reduces material costs compared to alternative methods.

In summary, Floor Deck Roll Forming Machines are tailored to concrete-supported flooring in multi-story buildings, while Steel Deck Roll Forming Machines provide more versatile profiles for both floors and roofs. Both are essential for creating durable, efficient, and high-strength construction solutions in modern building projects.

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)