The Floor Deck Roll Forming Machine: Engineering the Structural Platform

The floor deck roll forming machine is a cornerstone of modern construction, producing the critical corrugated steel profiles that form composite floors in multi-story buildings. This highly automated system transforms flat steel coil into strong, lightweight decking with exceptional speed and precision, revolutionizing how structural slabs are built.

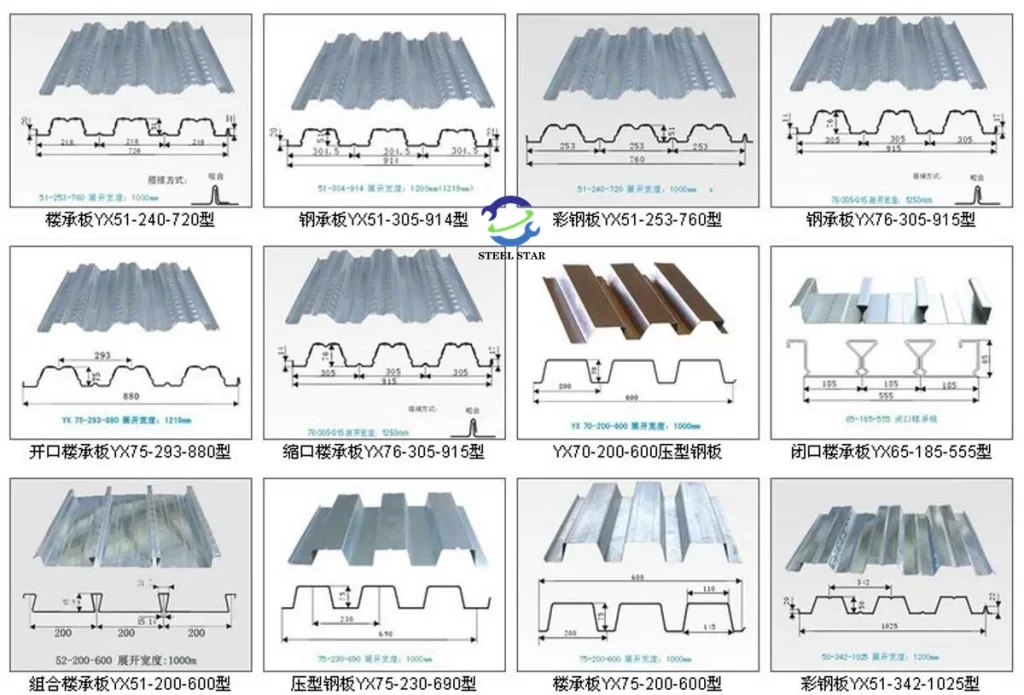

Core Function and Product

The machine manufactures floor decking (or composite decking), which serves a dual purpose: first, as permanent formwork for poured concrete; second, as tensile reinforcement (rebar) once bonded to the concrete, creating a strong, composite structural slab. The signature trapezoidal or re-entrant ribs provide mechanical interlock with the concrete and enhance load-bearing capacity.

The Roll Forming Process

The operation follows a continuous, cold-roll forming principle:

- Material Feed: A heavy-duty decoiler unwinds a coil of pre-galvanized or painted steel (typically 0.7mm-1.5mm thick).

- Pre-Punching (Optional but Common): A CNC punching unit precisely cuts embossments, service holes, or shear stud openings before forming. This ensures accuracy for on-site placement.

- Profile Formation: The steel strip passes through a sequential series of roll stations (12-20+ pairs). Each set of hardened steel rollers progressively bends the metal into the final complex ribbed profile.

- Cut-to-Length: A high-speed flying cut-off (hydraulic or servo) shears the continuously moving deck to exact, pre-set lengths without stopping production.

- Output & Stacking: Finished panels are automatically conveyed and stacked into orderly bundles for shipment.

Key Machine Components & Technology

- Roll Forming Mill: The core, featuring a rigid frame housing the precision roller dies. More stations allow for forming complex, deep-rib profiles with minimal stress.

- CNC Pre-Punching System: Essential for modern projects, allowing for customized hole patterns for MEP (mechanical, electrical, plumbing) penetrations and shear stud placement directly from BIM models.

- Servo-Driven Cut-Off: Provides millimeter accuracy for panel length, crucial for minimizing on-site waste and fit.

- PLC Control System: Integrates all components. Operators input panel parameters (length, rib height, punch pattern) via a touchscreen HMI for fully synchronized operation.

Advantages Over Traditional Methods

- Unmatched Speed & Volume: Produces tens of meters per minute, far outpacing manual fabrication.

- Superior Strength & Consistency: Cold working increases steel strength; every panel is dimensionally identical.

- Design Integration: Pre-punched decks align perfectly with construction drawings, accelerating on-site assembly of electrical conduits, stud welding, and other trades.

- Material Efficiency: Coil-to-finished-product process minimizes scrap generation.

Impact on Construction

This machine enables the fast-track construction of skyscrapers, parking garages, hospitals, and commercial complexes. By providing a ready-made, structurally integrated formwork system, it drastically reduces slab construction time, labor costs, and temporary works. The result is a lighter, stronger, and more efficient floor system that has become the global standard for steel-framed buildings.

The floor deck roll forming machine is a paradigm of industrial efficiency. It seamlessly bridges digital design (BIM) and physical construction, producing a key component that enhances the safety, speed, and economy of modern building projects. Its continuous hum is the sound of progress, literally forming the stable platforms upon which our built environment rises.

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)