Galvanized Steel Keel Roll Forming Machine: The Framework of Modern Construction

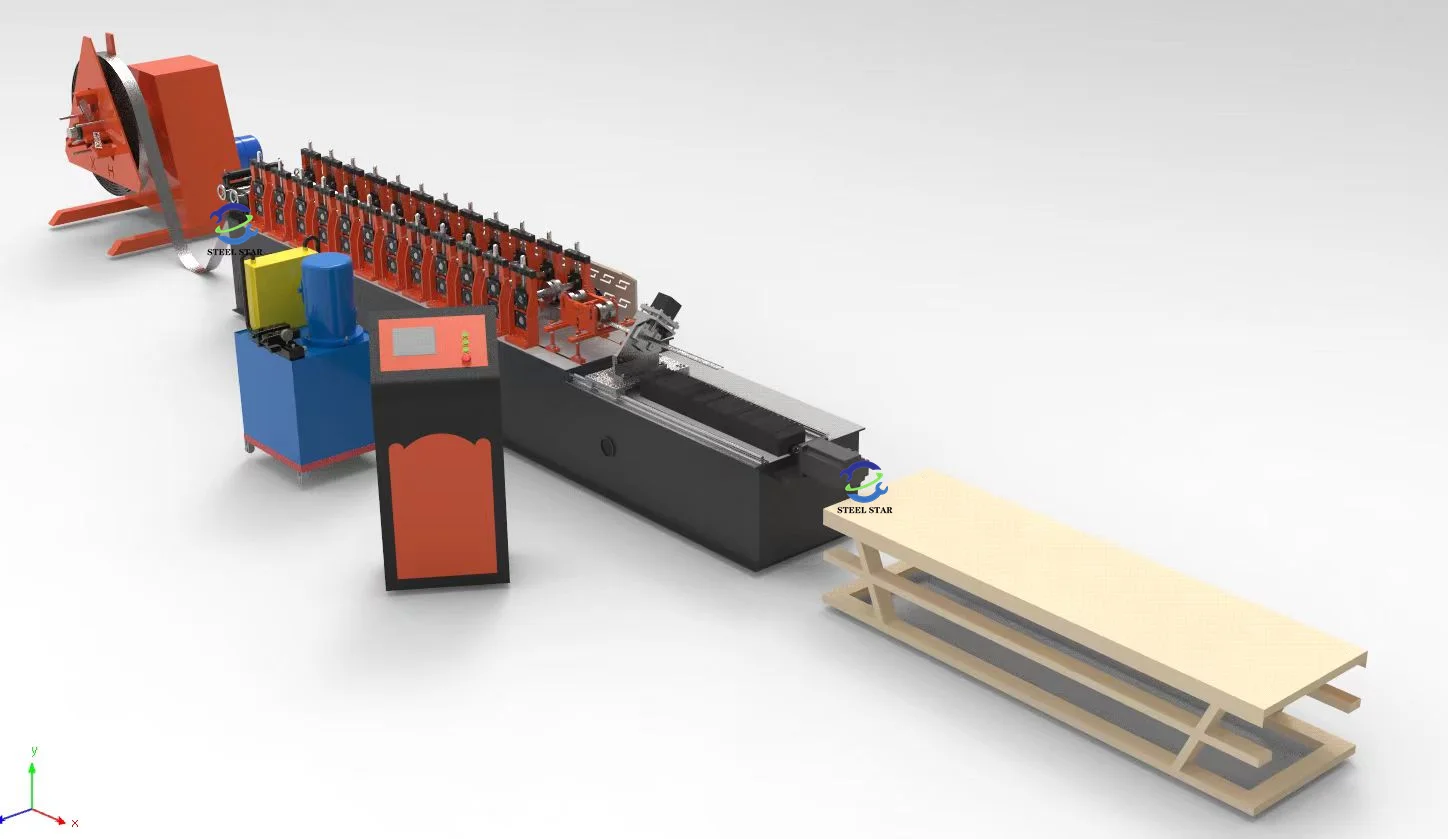

The Galvanized Steel Keel Roll Forming Machine is a specialized industrial equipment designed to transform galvanized steel coils into precise, lightweight structural components essential for contemporary construction. These machines produce the skeletal framework—known as steel keels or studs—that forms the backbone of drywall partitions, suspended ceilings, and exterior wall systems in commercial, industrial, and residential buildings worldwide.

Core Technology and Process

At its heart, the machine utilizes the cold roll forming process, a continuous and efficient method of shaping metal. The production sequence is meticulously engineered:

- Uncoiling and Leveling: A coil of galvanized steel strip, typically 0.4mm to 2.0mm in thickness, is mounted on a decoiler. The material first passes through a leveling unit to eliminate any coil curvature or internal stresses, ensuring a perfectly flat strip enters the forming section.

- Pre-Punching (Optional but Common): For keels requiring screw holes, service openings, or nesting features for strength, a precision servo-controlled punching station perforates the flat strip before forming. This is far more accurate than post-forming punching.

- Progressive Roll Forming: The flat strip is fed into a series of paired roller dies (forming stands). Each stand incrementally bends the strip by a few degrees, gradually forming the complex C-shape, U-shape, or other specialized profiles (like tracks and furring channels) without stretching or compromising the galvanized coating. This multi-stage approach ensures high precision and excellent material integrity.

- Precision Cutting: Once fully formed, the continuous keel passes through a high-speed cutting system. A computer-controlled flying cut-off—using carbide saws or hydraulic shears—cuts the profile to exact lengths (e.g., 2400mm, 3000mm) without stopping the production line, ensuring square, burr-free ends.

- Output and Stacking: Finished keels are automatically conveyed, counted, and bundled for strapping and palletizing, ready for shipment.

Key Technical Features

- High-Speed Servo Punching: Integrated, programmable punching units allow for flexible hole patterns and quick changeovers between different keel specifications.

- Precision Roll Design: The forming rolls, made from high-grade alloy steel and often chrome-plated, are precisely machined to create sharp corners, consistent webs, and uniform flanges critical for structural performance and easy installation.

- PLC Control System: A central Programmable Logic Controller synchronizes the entire line—from decoiler speed and punch patterns to cut length. Modern interfaces allow for storage of hundreds of product recipes.

- In-Line Quality Monitoring: Some advanced systems incorporate laser gauges or vision systems to continuously monitor critical dimensions like flange width, bow, and twist.

Importance in Construction

Galvanized steel keels offer significant advantages over traditional wooden framing: they are non-combustible, dimensionally stable (no warping or shrinking), immune to mold and pests, and 100% recyclable. The machine enables the mass production of these components with consistent quality, which is vital for:

- Interior Partition Walls: C-studs and U-tracks form lightweight, strong walls.

- Suspended Ceilings: Main runners, cross tees, and furring channels create grid systems.

- Exterior Wall and Soffit Framing: Providing a stable substrate for cladding materials.

- Modular Construction: Enabling the off-site fabrication of wall and ceiling panels.

Advancements and Trends

The latest generation of machines emphasizes flexibility and smart manufacturing. Quick-change cartridge systems allow for faster profile switching. Integration with IoT (Internet of Things) platforms enables predictive maintenance, production data analytics, and traceability for each bundle produced. Furthermore, machines are increasingly designed to handle alternative coated steels, such as aluminum-zinc alloy (AZ) or pre-painted coils, expanding their application scope.

The Galvanized Steel Keel Roll Forming Machine is more than just a fabricator; it is an enabler of modern, efficient, and resilient construction. By delivering high-strength, precision-engineered framing components at high volume, it directly supports faster building cycles, improved safety standards, and sustainable building practices. Its continuous innovation ensures that the hidden framework of our built environment remains robust, adaptable, and cost-effective.

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)