The Rain Gutter Roll Forming Machine: Shaping Functional Elegance.

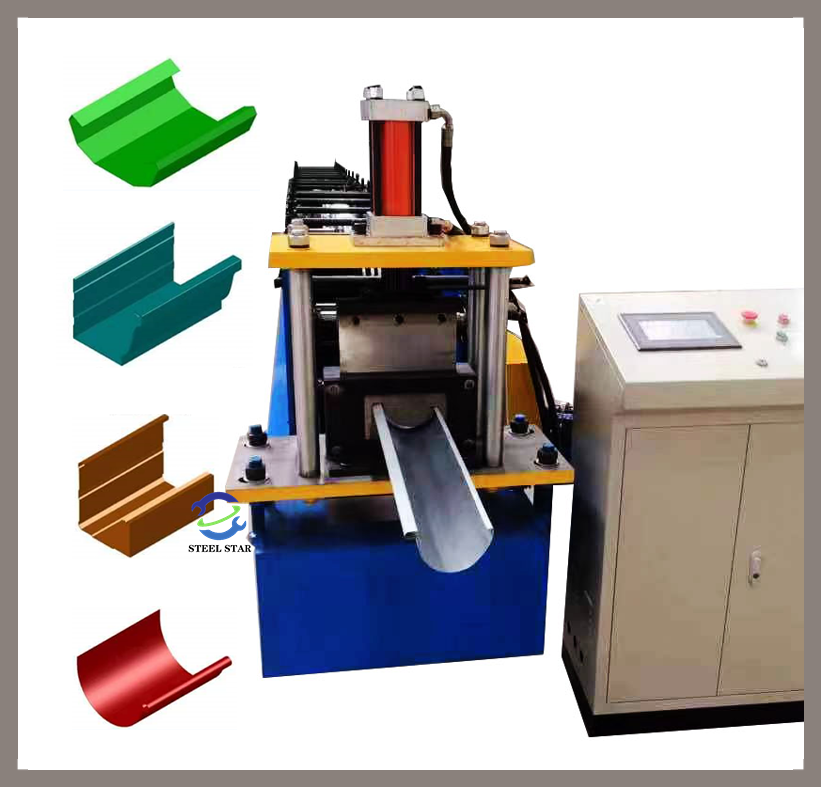

In the realm of modern construction and architecture, the rain gutter roll forming machine stands as a crucial piece of equipment that plays a vital role in ensuring the functionality and aesthetics of buildings. This specialized machinery is responsible for creating rain gutters, which are essential components for managing rainwater runoff and protecting structures from water damage.

How It Works

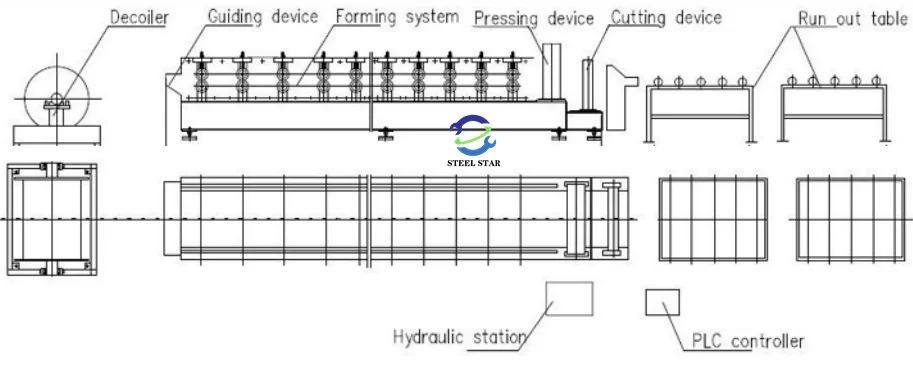

The operation of a rain gutter roll forming machine is a fascinating blend of precision engineering and continuous production. It begins with a coil of raw material, typically aluminum or steel, which is loaded onto the machine’s decoiler. The decoiler smoothly feeds the material into the forming section.

As the metal strip progresses through the machine, it passes through a series of precisely engineered rollers. These rollers are designed to gradually shape the flat strip into the desired profile of a rain gutter. The process is highly controlled, with each roller applying specific bends and contours to create the gutter’s shape. For example, the first few rollers might start by creating a gentle curve, while subsequent rollers refine the shape and add features such as flanges or seams.

Once the rain gutter has been fully formed, it is cut to the desired length by a cutting mechanism. This cutting can be done manually or automatically, depending on the sophistication of the machine. In some cases, advanced machines can even adjust the cutting length on the fly, allowing for greater flexibility in production.

Key Components

The rain gutter roll forming machine consists of several key components that work in harmony to produce high-quality gutters.

Decoiler: As mentioned earlier, the decoiler holds the coil of raw material and ensures a smooth feed into the machine. It is equipped with tension control mechanisms to maintain the proper tension on the metal strip as it enters the forming process.

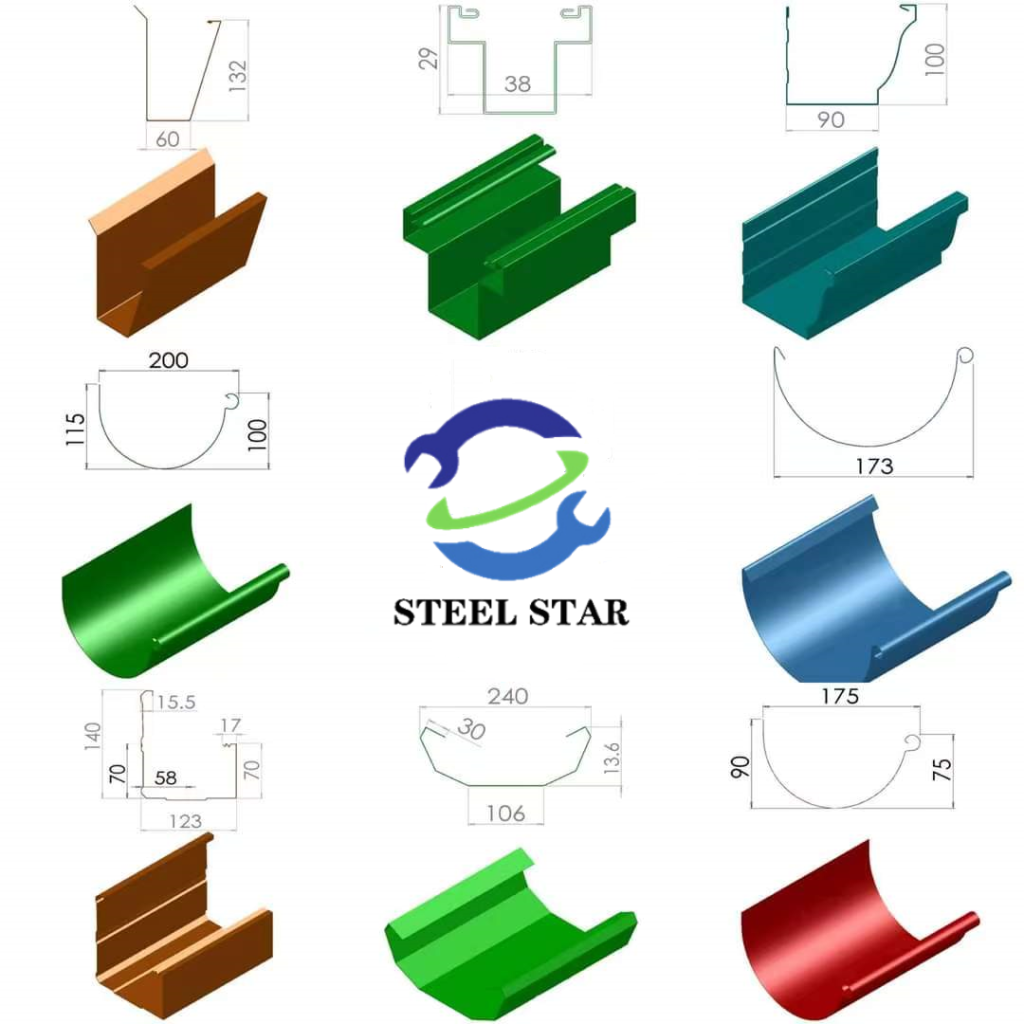

Forming Rollers: These are the heart of the machine. Made from high-quality materials and precisely machined, the forming rollers are responsible for shaping the metal strip into the rain gutter profile. Different sets of rollers can be used to create various gutter designs and sizes.

Cutting Device: The cutting device accurately cuts the formed gutter to the required length. It can be a simple manual cutter or a more advanced automated system with servo motors for precise cutting.

Control Panel: The control panel allows operators to adjust various parameters of the machine, such as roller speed, forming pressure, and cutting length. This enables the machine to be customized for different production requirements and gutter specifications.

Advantages in Production

The use of a rain gutter roll forming machine offers several significant advantages in the production process.

Efficiency: These machines can produce rain gutters at a rapid pace, significantly reducing production time compared to traditional manufacturing methods. This is especially important for large-scale construction projects where a large number of gutters are needed in a short period.

Cost-effectiveness: By automating the production process, labor costs are reduced. Additionally, the precise forming capabilities of the machine minimize material waste, resulting in cost savings over time.

Consistency: Every gutter produced by the machine is identical in shape and size, ensuring a seamless installation and a professional look. This consistency also makes it easier to replace damaged gutters in the future.

Customization: Rain gutter roll forming machines can be adjusted to produce gutters of different sizes, shapes, and materials, allowing for customization to meet the specific needs of different buildings and projects.

Applications in Construction

Rain gutters produced by these machines are widely used in various construction applications.

In residential buildings, rain gutters help protect the foundation and siding from water damage. They also direct rainwater away from walkways and driveways, preventing erosion and 滑倒 hazards. Different styles of gutters, such as seamless aluminum gutters or decorative copper gutters, can enhance the curb appeal of a home.

In commercial and industrial buildings, rain gutters are essential for managing large volumes of rainwater runoff. They are often designed to be more durable and capable of handling heavier loads. For example, in a large warehouse or factory, gutters with larger capacities and stronger materials are required to ensure proper drainage.

Innovations and Future Trends

As technology continues to advance, rain gutter roll forming machines are also evolving. One trend is the integration of digital control systems that offer even greater precision and flexibility. These systems can be programmed to produce complex gutter designs and can automatically adjust parameters based on real-time feedback.

Another innovation is the use of new materials and coatings. For instance, some manufacturers are exploring the use of recycled materials to create environmentally friendly gutters. Additionally, advanced coatings can provide enhanced durability, corrosion resistance, and self-cleaning properties.

In conclusion, the rain gutter roll forming machine is a crucial tool in the construction industry. Its ability to produce high-quality, efficient, and customizable rain gutters makes it an essential asset for builders, architects, and contractors. As the industry continues to evolve, these machines will undoubtedly play an even more significant role in shaping the future of building design and functionality.

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)