Gutter Bending Machine: Precision Fabrication for Weather Management Systems

A Gutter Bending Machine is a specialized fabrication system designed to transform flat metal sheets or pre-formed gutter profiles into precise, custom-shaped components for rainwater management systems. This equipment plays a critical role in producing the angled sections, miters, downspout transitions, and formed ends necessary for complete gutter installation in residential, commercial, and architectural applications.

Core Functions and Applications

Unlike continuous roll forming machines that produce straight lengths, gutter bending machines focus on creating precise bends in pre-cut gutter sections. Their primary functions include:

- Miter Creation: Forming precise corner angles (typically 90°, 135°, or custom angles) for seamless gutter connections

- End Cap Forming: Shaping and closing gutter ends with integrated drip edges

- Drop Outlet Formation: Creating formed outlets for downspout connections

- Box Miter Fabrication: Producing complex transitions for box gutter systems

- Architectural Details: Forming decorative ends and custom profiles for historical or design-focused applications

Technology Types and Operating Principles

Modern gutter bending machines utilize several distinct technologies:

1. Press Brake Style Benders:

- Utilize precision-matched male and female dies

- Capable of handling various metals (aluminum, copper, galvanized steel)

- Offer high repeatability for production environments

- May incorporate automated back gauges for precise bend positioning

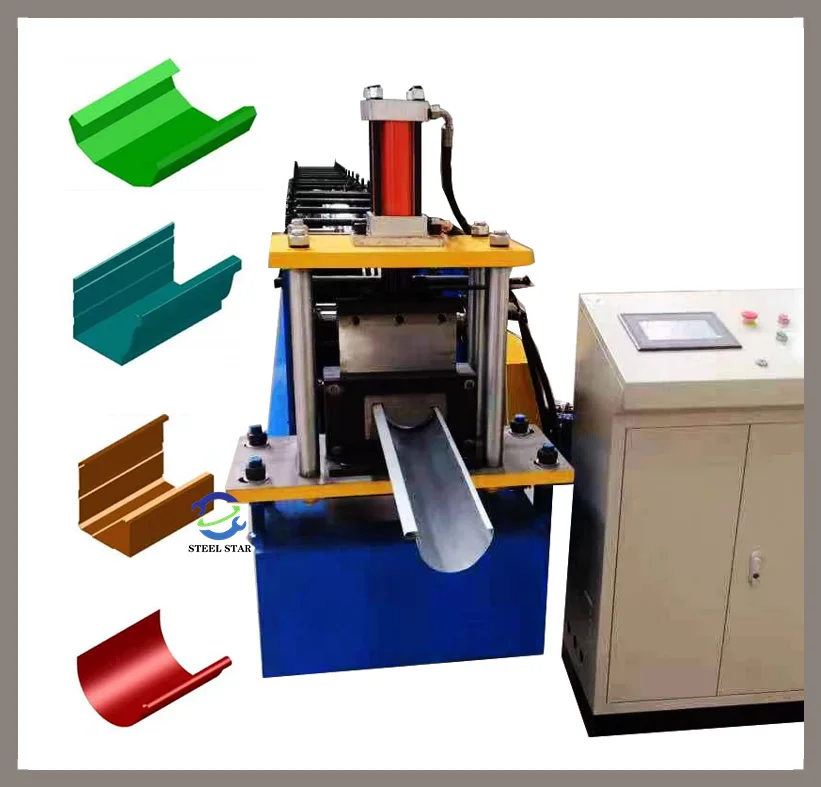

2. Roll Form Bending Systems:

- Use three-roll configurations to gradually form curves

- Ideal for larger radius bends and architectural applications

- Minimize material deformation and surface marking

3. Computer-Numeric-Control (CNC) Machines:

- Integrate multiple operations (punching, notching, bending)

- Store complex programs for different gutter profiles and angles

- Provide highest precision for custom architectural work

- Often include automatic tool changers for different operations

Key Components and Features

Material Handling System:

- Precision hold-down mechanisms to secure gutter sections

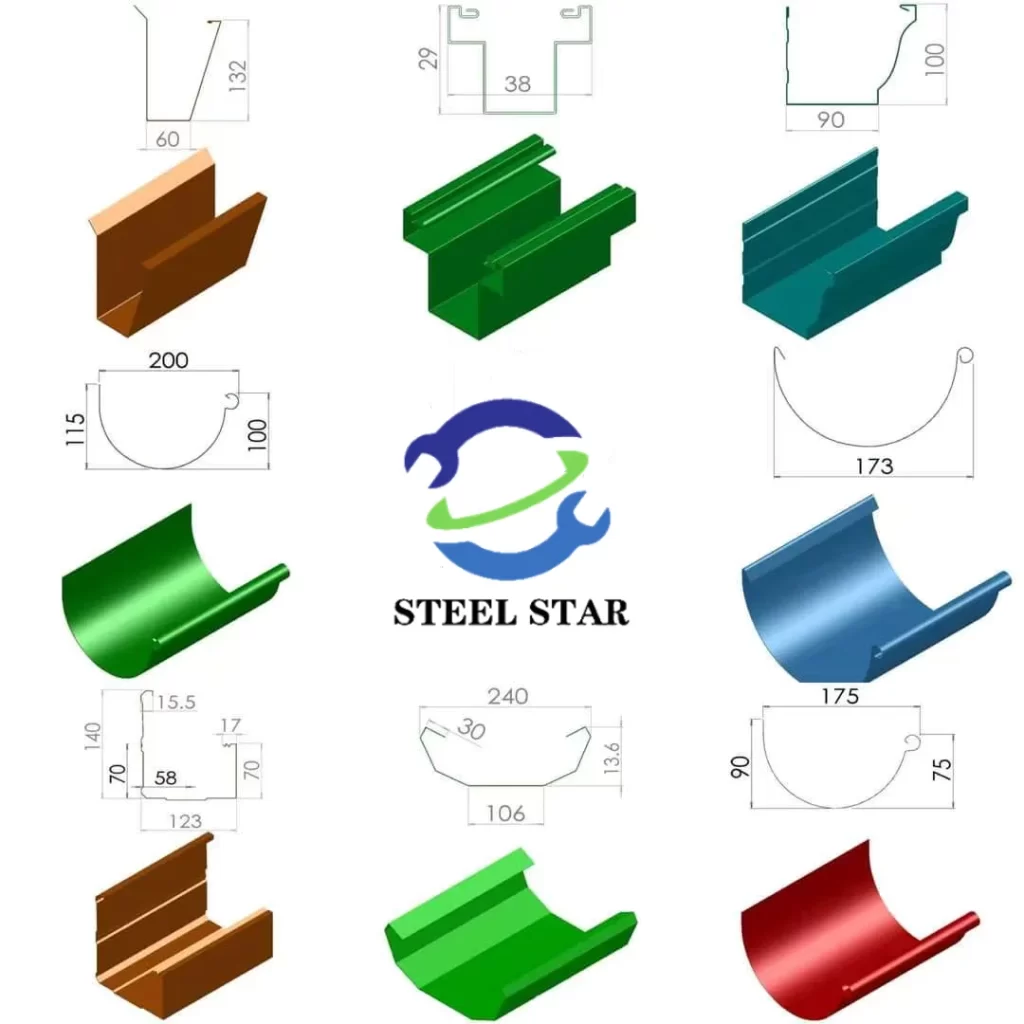

- Adjustable supports for different profile sizes (K-style, half-round, fascia)

- Protective coatings on contact surfaces to prevent material marring

Bending Mechanism:

- Hydraulic or electric servo-driven actuators

- Programmable bend angle controls (±0.5° accuracy)

- Quick-change tooling systems for different gutter profiles

Measurement and Positioning:

- Laser or mechanical back gauges for precise material placement

- Digital angle measurement displays

- Memory functions for storing common bend sequences

Control Systems:

- PLC-based controls with touchscreen interfaces

- Pre-programmed routines for standard gutter configurations

- Diagnostic systems for maintenance and troubleshooting

Technical Advantages

Precision Engineering:

- Consistent, accurate bends ensuring water-tight installations

- Elimination of guesswork and manual measurement errors

- Perfect miters that reduce sealant requirements and installation time

Material Efficiency:

- Minimizes waste through precise bend placement

- Reduces trial-and-error material losses

- Optimizes use of expensive materials like copper and painted aluminum

Production Efficiency:

- Dramatically faster than manual methods (up to 10x productivity increase)

- One-person operation capability

- Consistent quality regardless of operator skill level

Versatility:

- Handles multiple gutter profiles with quick changeovers

- Accommodates various material thicknesses

- Capable of both production runs and custom one-off pieces

Industry Impact and Applications

Residential Gutter Installation:

- Enables custom fabrication on-site or in shop environments

- Supports the growing trend of seamless gutter systems

- Facilitates repair and replacement of specific sections

Commercial and Historical Projects:

- Essential for complex box gutter systems in commercial buildings

- Critical for replicating historical profiles in restoration work

- Enables fabrication of large-scale commercial systems

Manufacturing and Distribution:

- Used by gutter manufacturers for producing custom components

- Employed by distributors for fabricating special-order pieces

- Integral to prefabricated gutter system production

Technological Evolution

Modern machines incorporate several advanced features:

- CAD/CAM Integration: Direct import of architectural drawings

- Vision Systems: Camera-based alignment for perfect bend placement

- Automatic Profile Recognition: Sensors that identify gutter type and dimensions

- Cloud Connectivity: Remote monitoring and program sharing capabilities

- Energy-Efficient Designs: Regenerative hydraulic systems and servo drives

Economic and Environmental Benefits

Cost Reduction:

- Lower labor costs through increased efficiency

- Reduced material waste (typically 15-25% savings)

- Decreased installation time and callbacks

Quality Improvement:

- Professional-grade results achievable by all operators

- Consistent quality across multiple installations

- Enhanced durability through precision fabrication

Sustainability Impact:

- Reduced material consumption

- Longer-lasting installations with proper water management

- Support for recycled metal materials

Operational Considerations

Safety Features:

- Two-hand operation controls

- Light curtains and safety barriers

- Emergency stop systems

- Automatic tool locking mechanisms

Maintenance Requirements:

- Regular lubrication systems

- Wear part monitoring

- Hydraulic system maintenance schedules

- Calibration procedures

Training and Support:

- Comprehensive operator training programs

- Technical support hotlines

- Online resources and video tutorials

- Regular software updates

Future Developments

The gutter bending machine industry continues evolving with:

- Increased Automation: Robotic loading and unloading systems

- Smart Technology Integration: IoT monitoring for predictive maintenance

- Advanced Materials Capability: Handling new composites and coated metals

- Mobile Applications: Compact, trailer-mounted units for on-site fabrication

- Sustainability Focus: Energy recovery systems and eco-friendly designs

The Gutter Bending Machine represents a significant advancement in rainwater management fabrication technology. By combining precision engineering with user-friendly operation, these machines have transformed gutter fabrication from a craft-dependent process to a precise, repeatable manufacturing operation. As architectural designs become more complex and quality expectations continue to rise, these machines provide the essential technology bridge between raw materials and perfectly functioning weather management systems. Their role in enabling efficient, waste-free production of durable gutter systems ensures they remain indispensable tools for roofing contractors, metal fabricators, and construction professionals dedicated to quality and efficiency in building envelope protection.

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)