Gutter Downspout Machine: Engineering Efficient Water Management Systems

In the world of modern construction and architectural detailing, efficient rainwater management is not merely a functional necessity but a critical component of a building’s long-term durability and aesthetics. At the core of producing the essential components for these systems—gutters and downspouts—lies the Gutter Downspout Machine. This specialized roll-forming equipment is engineered to transform pre-coated metal coils into precise, durable, and ready-to-install rainwater conveyance components with high efficiency and consistency.

The Product: Gutters and Downspouts

Gutters (eavestroughs) are channels installed along the eaves of a roof to collect and divert rainwater. Downspouts (or leaders) are the vertical pipes that carry the water from the gutters down to ground level, away from the building’s foundation. These components are typically fabricated from durable, corrosion-resistant materials such as:

- Galvanized Steel (often with a protective paint coating)

- Aluminum (lightweight and rust-proof)

- Copper (for premium, architectural applications)

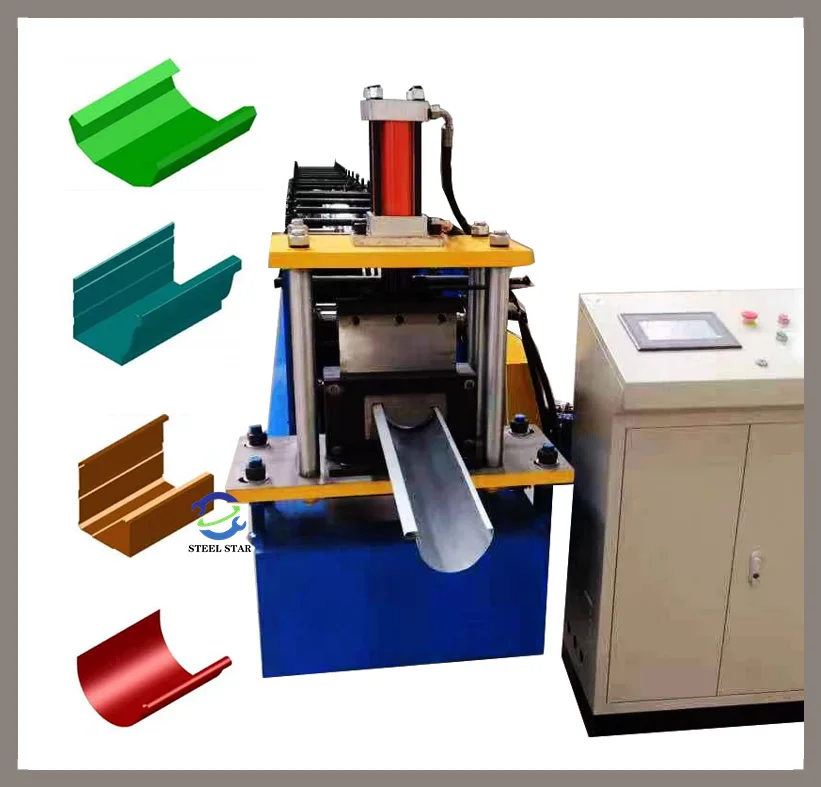

Core Function of the Machine

A Gutter Downspout Machine is a type of continuous cold roll-forming production line. Its primary function is to take a flat metal coil and, through a progressive series of forming operations, shape it into a finished gutter profile or a locked-seam downspout pipe without any welding. The process work-hardens the metal at the bends, enhancing the strength of the final product.

Types of Machines and Outputs

Machines are generally configured for specific profiles:

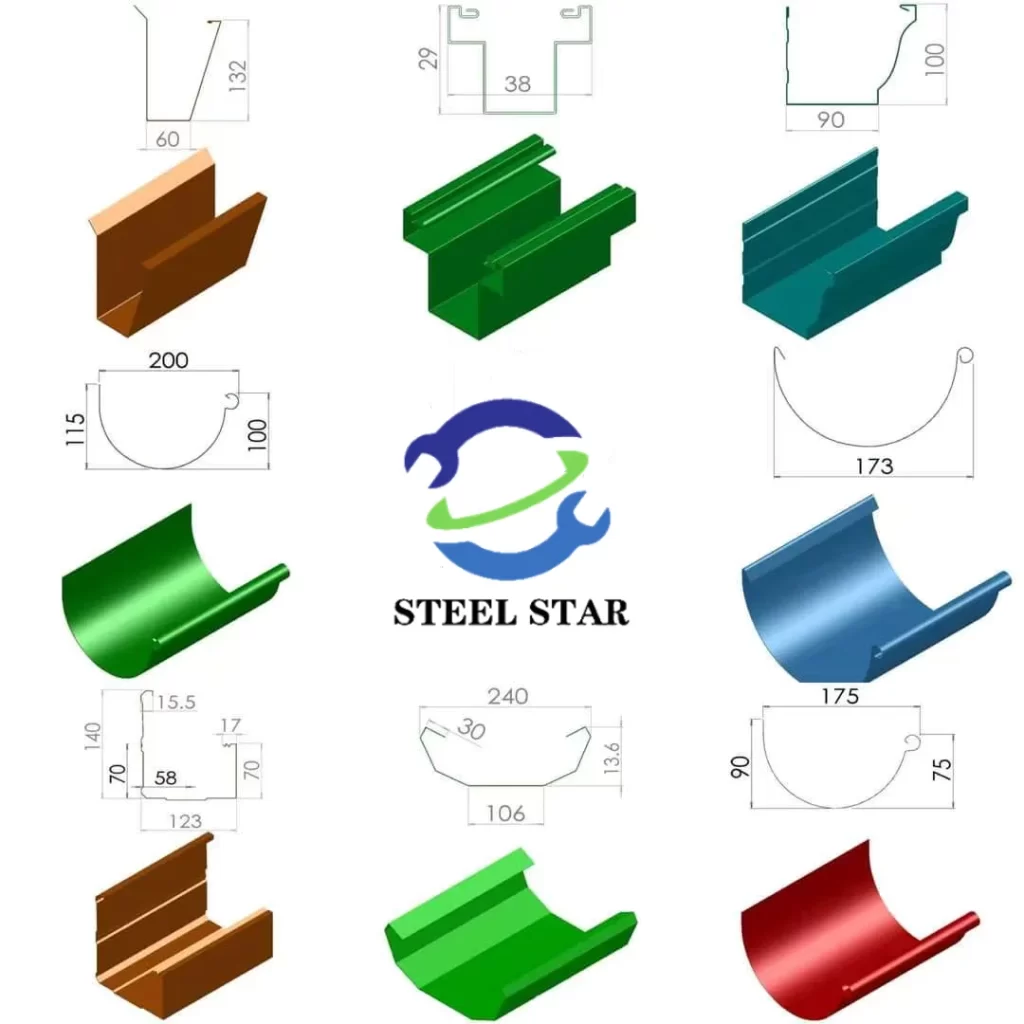

- Gutter Machine: Produces various gutter profiles.

- K-Style Gutter: The most common residential profile in North America, resembling crown molding with a decorative front face.

- Half-Round Gutter: A classic, smooth, semi-circular profile often used in traditional or historic-style architecture.

- Box Gutter / Fascia Gutter: A rectangular profile often used in commercial construction, sometimes integrated into the building’s fascia.

- Downspout Machine: Produces the accompanying downspout pipes.

- Rectangular Downspout: Typically matches K-style gutters.

- Round Downspout: Pairs with half-round gutters. More advanced machines can form a round downspout from a flat coil and create a locked (or button-punch) seam for integrity.

Many modern systems are combination lines that can produce both gutters and downspouts by changing the set of roll-forming tooling.

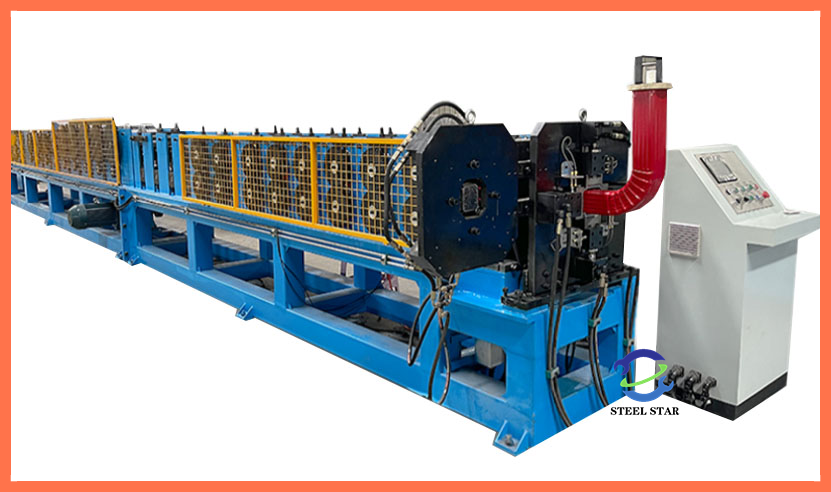

Anatomy of a Standard Machine

A complete automated line integrates several key stations:

- Decoiler / Uncoiler: Holds the heavy metal coil and feeds it into the machine under controlled tension.

- Feeding & Guiding System: Ensures the strip enters the forming section perfectly straight and aligned.

- Pre-Punching / Notching Unit (Optional but Common): A servo-driven punching station can add precise holes for downspout outlets, end caps, or fastener points before the metal is formed. This is a critical feature for accuracy and speed.

- Roll-Forming Section: The heart of the machine. A series of contoured, hardened steel rollers mounted on sturdy shafts progressively bend the metal strip into the final cross-sectional profile. Each set of rolls (a “stand”) makes a small, incremental bend.

- Cut-Off System: A hydraulic or servo-electric flying cut mechanism that cleanly shears the continuously moving formed product to pre-set lengths without stopping the line.

- Control System: A Programmable Logic Controller (PLC) with a Human-Machine Interface (HMI) touchscreen allows the operator to set all parameters (length, quantity, punch patterns) and monitors the entire process.

- Run-Out Table & Stacker: Supports the finished product as it exits and stacks it neatly for bundling.

Technological Advantages and Features

- High-Speed Production: Modern machines can operate at speeds of 30-60 meters per minute, producing large volumes of material with minimal labor.

- Exceptional Consistency: Every piece produced is identical in dimensions and shape, ensuring seamless fitment during installation and a professional appearance.

- Material Efficiency & Low Waste: The roll-forming process and precision cutting minimize scrap material compared to manual fabrication.

- Flexibility: Quick-change tooling allows a single machine to produce multiple profiles and sizes (e.g., 5-inch and 6-inch K-style), making it adaptable to market demands.

- In-Line Accessory Formation: Advanced lines can include stations to form related components like gutter brackets, end caps, or miters directly from coil stock.

Impact on the Industry

The Gutter Downspout Machine has professionalized and scaled the rainwater system manufacturing industry:

- Enabling Specialized Fabricators: It allows roofing suppliers and metal fabricators to produce custom-length components on-demand, reducing inventory costs for pre-made pieces.

- Improving Quality & Durability: Factory-produced, consistently formed gutters have tighter seams and more uniform shapes than field-fabricated ones, leading to better performance and longevity.

- Supporting Architectural Variety: By making various profiles readily available, it gives architects, builders, and homeowners more choice to match the functional and aesthetic requirements of any project.

The Gutter Downspout Machine is a prime example of focused industrial automation solving a specific construction need. By efficiently transforming raw coil into precise, high-quality building components, it plays a vital but often unseen role in protecting structures from water damage. Its combination of mechanical precision, operational speed, and programmable flexibility makes it an indispensable asset for manufacturers, ultimately contributing to more durable, efficient, and well-designed buildings. As building codes continue to emphasize proper water management, the technology behind these machines will remain essential in the construction supply chain.

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)