Gutter Roll Forming Machine: An Essential Guide to Modern Rainwater Management Manufacturing

Gutter roll forming machines represent a specialized category of cold roll forming equipment that transforms flat metal coils into precise, continuous gutter profiles for residential, commercial, and industrial rainwater management systems. These automated production lines have revolutionized gutter manufacturing by replacing labor-intensive manual methods with high-speed, precision engineering solutions that deliver consistent quality and superior production efficiency.

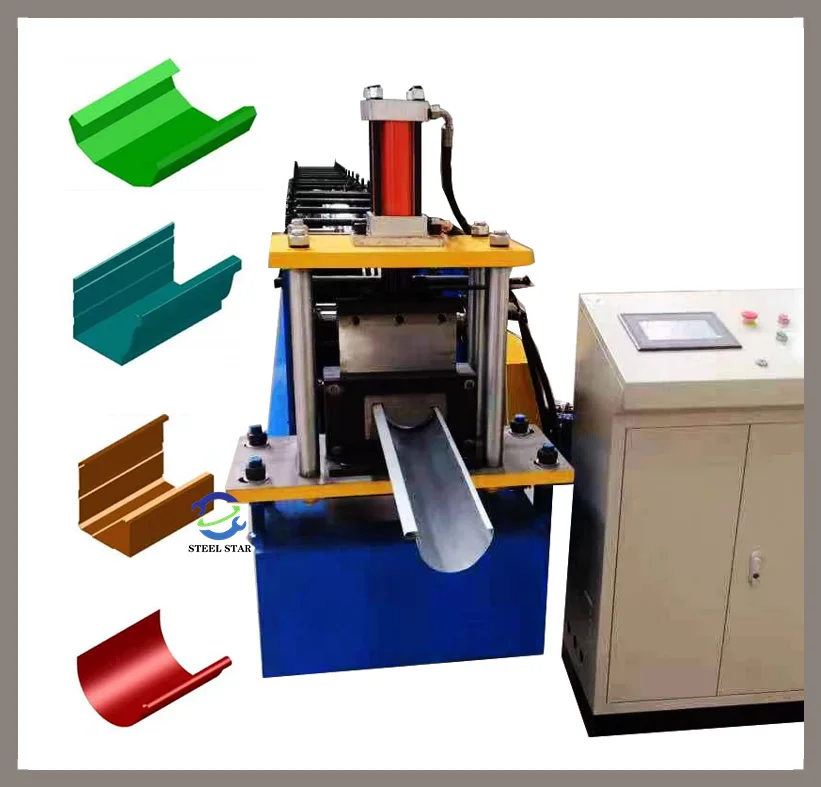

Core Components and Machine Architecture

A standard gutter roll forming machine consists of several integrated subsystems:

1. Decoiling and Feeding System

- Heavy-Duty Decoiler: Equipped with hydraulic expansion mandrels capable of handling coils up to 3,000 kg with diameters of 600-1,500 mm

- Coil Loading Equipment: Hydraulic or electric coil carts for safe material handling

- Feeding Mechanism: Powered entry guides with tension control to ensure smooth material flow

- Pre-Leveling Unit: 5-9 roll levelers to eliminate coil curvature before forming

2. Roll Forming Station

- Forming Stands: Typically 12-18 stations with progressively shaped rollers

- Roller Design: Precision-machined from hardened alloy steel (HRC 58-62) with chrome or nickel plating for extended life

- Shaft and Bearing Assembly: Heavy-duty construction with replaceable bronze or roller bearings

- Quick-Change System: Allows rapid profile switching for different gutter designs

3. Cutting and Control Systems

- Hydraulic Flying Cutoff: Computer-controlled shear for precise length cutting while material moves continuously

- Programmable Logic Controller (PLC): Industrial-grade automation system (Siemens, Mitsubishi, or Allen-Bradley)

- Human-Machine Interface (HMI): Touchscreen panel for parameter setting, monitoring, and diagnostics

- Length Measurement: Rotary encoder or laser measurement for ±1 mm accuracy

4. Post-Forming Operations

- Embossing Units: For adding decorative patterns or brand logos

- Hole Punching Stations: For downspout connections and mounting hardware

- Automated Stacking: Pneumatic or robotic stacking systems with counting functions

- Safety Enclosures: Full machine guarding with interlock systems

Production Capabilities and Technical Specifications

Material Compatibility

- Galvanized Steel: Standard G90, G115, or higher coatings

- Pre-Painted Galvanized Iron (PPGI): Polyester, PVDF, or SMP coatings

- Aluminum Alloys: 3003, 3004, or 5052 grades

- Copper and Zinc: For premium architectural applications

- Material Thickness: 0.4 mm to 1.2 mm

- Coil Width Range: 200 mm to 600 mm

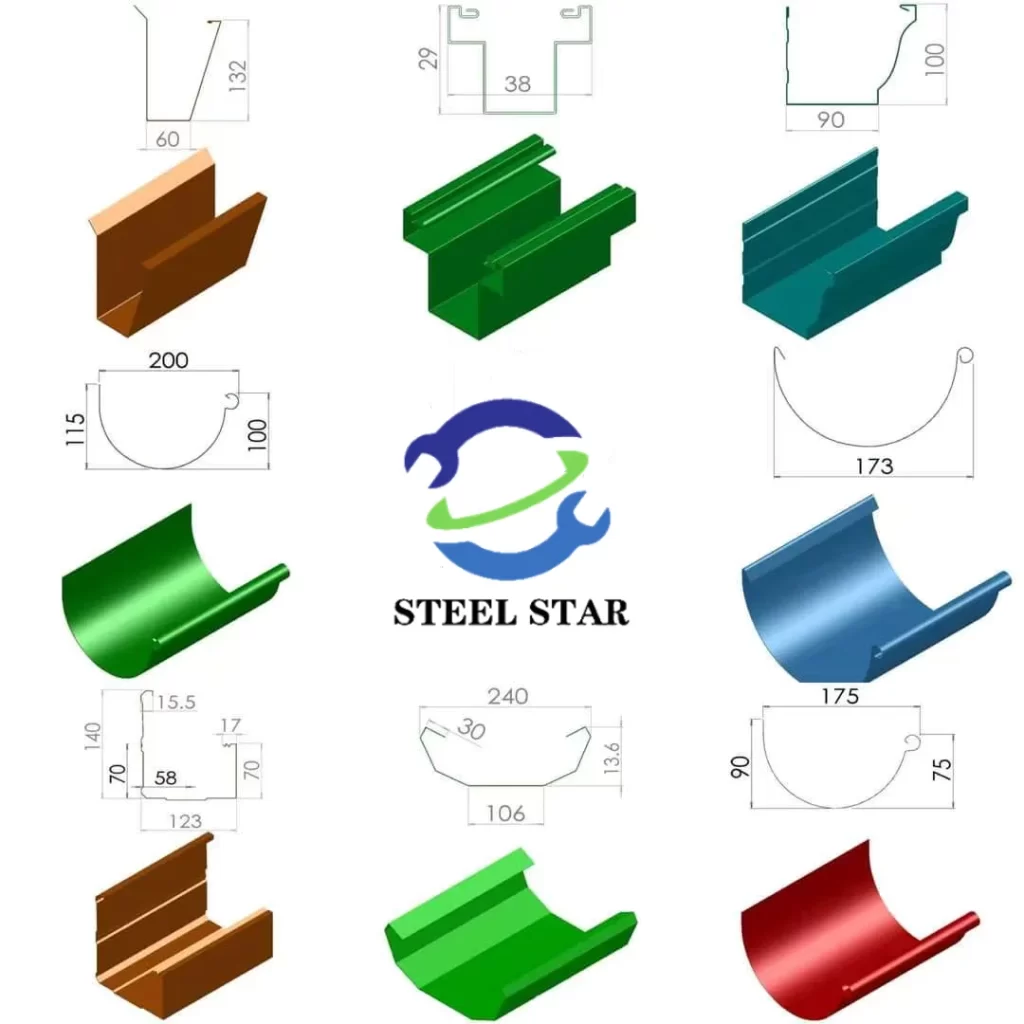

Profile Variety

- K-Style Gutters: Most common residential profile with decorative front

- Half-Round Gutters: Traditional profile for historical or premium installations

- Box Gutters: Large-capacity commercial and industrial systems

- Fascia Gutters: Integrated roof drainage solutions

- Custom Profiles: Manufacturer-specific designs

Performance Parameters

- Production Speed: 15-45 meters per minute

- Length Accuracy: ±1 mm to ±3 mm depending on system

- Daily Output: 3,000-10,000 linear meters (8-hour shift)

- Power Requirements: 15-45 kW depending on configuration

- Machine Dimensions: 15-25 meters length × 2-3 meters width

Advanced Features and Technological Innovations

Automation Enhancements

- Servo-Driven Systems: For precise synchronization of all moving components

- Automatic Lubrication: Centralized oil circulation for forming stations

- Remote Monitoring: IoT connectivity for production tracking and maintenance alerts

- Vision Inspection Systems: Camera-based quality control for surface defects

Operational Intelligence

- Recipe Management: Storage for multiple profile parameters

- Production Reporting: Automatic generation of production data and efficiency reports

- Predictive Maintenance: Vibration and temperature monitoring for component health

- Energy Management: Variable frequency drives for optimal power consumption

Industry Applications and Market Segments

Residential Construction

- New home construction projects

- Roof replacement and renovation

- Custom architectural installations

- DIY home improvement market

Commercial and Institutional

- Office buildings and retail centers

- Educational and healthcare facilities

- Government and municipal buildings

- Hotel and hospitality developments

Industrial Applications

- Warehouse and logistics facilities

- Manufacturing plants

- Agricultural buildings

- Sports complexes and arenas

Selection Criteria for Manufacturers

Technical Considerations

- Production Volume Requirements

- Low-volume: Manual or semi-automatic machines

- Medium-volume: Standard automated lines

- High-volume: Fully integrated systems with robotics

- Profile Complexity

- Simple profiles: Fewer forming stations

- Complex designs: Additional stations and special tooling

- Multiple profiles: Quick-change systems

- Material Requirements

- Coating preservation needs

- Thickness range capabilities

- Special alloy compatibility

Supplier Evaluation Factors

- Manufacturing Experience: Minimum 5-10 years in roll forming

- Technical Support: Installation, training, and ongoing assistance

- Spare Parts Availability: Local or rapid international supply

- Certifications: ISO, CE, or other relevant standards

- Customer References: Verified installations in similar applications

Installation and Operational Requirements

Facility Preparation

- Floor Space: 20-30 meters × 4-5 meters for machine plus material handling

- Foundation: Level concrete floor with adequate load capacity

- Power Supply: 380V/50Hz or 440V/60Hz three-phase with proper grounding

- Compressed Air: 0.6-0.8 MPa clean, dry air supply

- Material Handling: Overhead cranes or forklift access

Operator Training

- Basic machine operation (3-5 days)

- Tooling changeover procedures

- Routine maintenance tasks

- Safety protocol implementation

- Troubleshooting common issues

Maintenance and Service Protocols

Preventive Maintenance Schedule

- Daily: Cleaning, visual inspection, lubrication check

- Weekly: Bolt tightening, guide alignment, hydraulic system check

- Monthly: Roll inspection, bearing examination, electrical testing

- Quarterly: Complete calibration, wear component replacement

- Annually: Major overhaul, system upgrade evaluation

Critical Spare Parts Inventory

- Forming rolls and shafts

- Cutting blades and hydraulic components

- Drive system parts (gears, chains, motors)

- Electrical components (PLCs, sensors, controllers)

- Wear parts (guides, bearings, seals)

Economic Analysis and ROI Considerations

Investment Components

- Machine Cost: $50,000 to $250,000+ depending on configuration

- Tooling Investment: $10,000 to $50,000 for profile sets

- Installation Costs: 5-15% of machine cost

- Training and Commissioning: Typically included by reputable suppliers

Operational Economics

- Production Efficiency: 4-8 times faster than traditional methods

- Material Utilization: 92-97% efficiency through optimized cutting

- Labor Requirements: 1-3 operators versus 5-8 for manual production

- Quality Consistency: Reduced rejection rates and rework

- Typical ROI Period: 12-24 months for moderate to high production volumes

Safety Features and Compliance

Integrated Safety Systems

- Emergency stop circuits with redundant activation points

- Light curtain protection at entry and exit points

- Mechanical guarding on all moving components

- Electrical safety isolation and lockout/tagout provisions

- Noise reduction enclosures (typically <80 dB)

- Ergonomic design for operator comfort and safety

Environmental Considerations

Sustainable Manufacturing Features

- Energy-efficient motor systems with regenerative capabilities

- Scrap collection and recycling systems

- Noise pollution control measures

- Oil containment and recycling for hydraulic systems

- Compatibility with recycled metal content

- Reduced waste through precision manufacturing

Future Trends and Technological Developments

Industry 4.0 Integration

- Full digital twin implementation for virtual testing

- AI-driven optimization of production parameters

- Blockchain integration for supply chain transparency

- Augmented reality for maintenance and training

Advanced Material Processing

- High-strength lightweight alloy compatibility

- Composite material forming capabilities

- In-line coating and finishing options

- Smart material integration with embedded sensors

Sustainability Innovations

- Solar-powered operation options

- Water recycling systems for cooling

- Biodegradable hydraulic fluids compatibility

- Carbon footprint tracking and reporting

The gutter roll forming machine has evolved from a simple forming device to a sophisticated manufacturing system that combines precision engineering, advanced automation, and intelligent control. For manufacturers in the building products sector, investing in modern gutter roll forming technology represents a strategic decision with significant competitive implications.

These systems enable producers to:

- Respond rapidly to market demands with flexible production capabilities

- Maintain consistent quality across large production runs

- Reduce manufacturing costs through automation and material optimization

- Expand product offerings with custom profile capabilities

- Enhance workplace safety through engineered safeguards

- Improve sustainability through efficient resource utilization

As urban development continues globally and building standards evolve for better rainwater management, the demand for high-quality gutter systems will continue to grow. Manufacturers equipped with advanced roll forming technology will be best positioned to meet this demand while achieving superior operational efficiency and profitability.

The future of gutter manufacturing lies in increasingly intelligent, connected, and sustainable production systems that not only form metal but also generate data, optimize processes, and adapt to changing market conditions – all hallmarks of the modern gutter roll forming machine.

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)