The Highway Guardrail Forming Machine: Engineering Safety at High Speed

Highway guardrails, those seemingly simple ribbons of steel lining our roads, represent one of the most critical safety features in modern transportation infrastructure. Behind these life-saving barriers lies a remarkable piece of industrial engineering: the highway guardrail forming machine. This specialized equipment transforms raw steel into precisely formed crash barriers through an ingenious cold-forming process that combines speed, precision, and remarkable efficiency.

The Critical Role of Highway Guardrails

Before examining the machine itself, it’s essential to understand what it produces. Highway guardrails, or crash barriers, serve as passive safety systems designed to:

- Redirect errant vehicles back onto the roadway

- Absorb and dissipate crash energy

- Prevent vehicles from leaving the road entirely

- Minimize injury to vehicle occupants

These systems must meet rigorous national and international standards for impact resistance, strength, and durability. The precision required for these safety components makes their manufacturing process particularly demanding.

Anatomy of a Guardrail Forming Machine

A modern highway guardrail forming machine is a complete production line comprising several integrated systems:

1. Coil Loading and Feeding System

The process begins with massive steel coils, typically weighing 3 to 10 tons, made from galvanized or plain carbon steel. An automated decoiler unspools the coil, while a precision leveling system removes any curvature or imperfections from the steel strip. This initial preparation ensures consistent material enters the forming process.

2. Progressive Roll Forming Station

This is the heart of the machine, where flat steel transforms into the distinctive guardrail profile. The station consists of 12 to 24 consecutive roll stands, each performing an incremental bending operation. The rollers, made from hardened tool steel or carbide, gradually shape the metal through precisely calculated geometries.

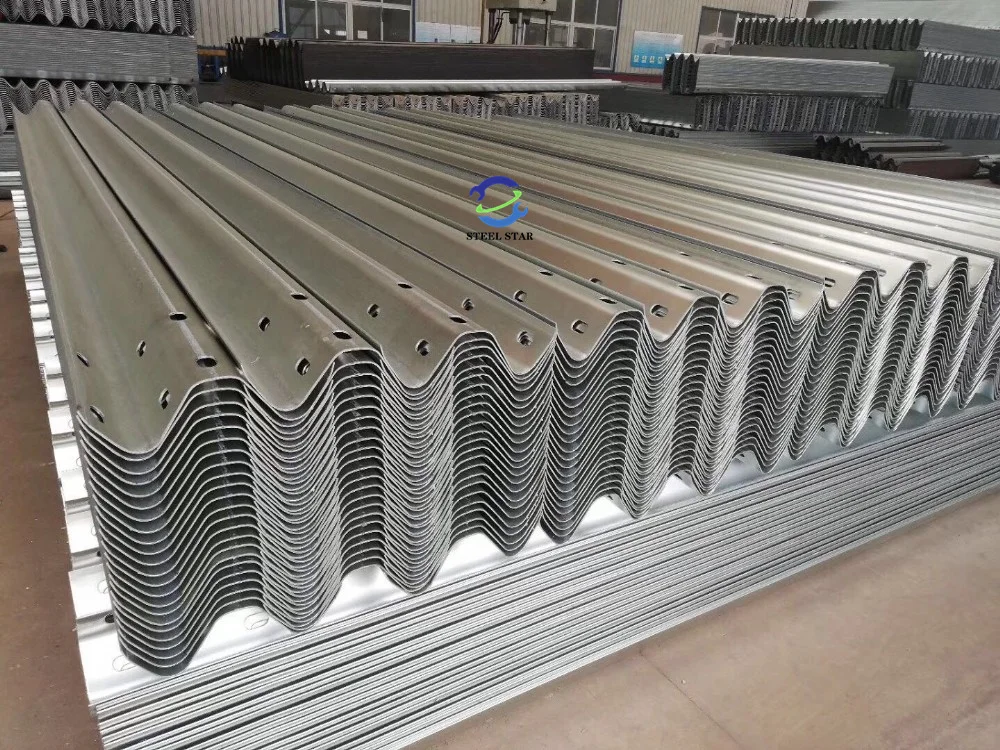

The most common profiles produced include:

- W-beam guardrail: The classic corrugated profile that provides strength through geometry

- Thrie-beam guardrail: A taller, three-wave profile for higher containment levels

- Box beam guardrail: A hollow rectangular section used in specific applications

- Post sections: Various support post profiles

Each stand in the forming line adds another degree of shape until the final profile emerges with exacting consistency.

3. Punching and Notching Systems

Integrated punching units create the precisely spaced bolt holes, slots, and notches that allow guardrail sections to interconnect. Modern machines use servo-electric punching systems that can produce complex hole patterns while the material moves continuously through the line, maintaining production speeds up to 40 meters per minute.

4. Precision Cutting Mechanism

A flying cut-off system, synchronized with the moving guardrail, cuts the continuous formed section to exact lengths (typically 3.8m, 4m, or 7.6m). Advanced systems employ hydraulic or servo-driven shears that produce clean, burr-free ends without deformation.

5. Control and Automation Systems

Modern machines are governed by sophisticated PLC (Programmable Logic Controller) systems that monitor every aspect of production. Touch-screen interfaces allow operators to control parameters such as:

- Production speed

- Cut lengths

- Punching patterns

- Quality check parameters

Technical Specifications and Capabilities

High-performance guardrail forming machines exhibit remarkable specifications:

- Material thickness: 2.0mm to 4.5mm

- Material width: Up to 600mm for thrie-beam profiles

- Line speeds: 15-45 meters per minute

- Length accuracy: ±1mm

- Tooling life: 8,000-15,000 tons of production before refurbishment

- Power requirements: 75-200 kW depending on configuration

The Manufacturing Process: Step by Step

- Material Inspection: Incoming steel coils undergo quality checks for thickness consistency and surface defects.

- Coil Loading: Overhead cranes position coils on the decoiler mandrel.

- Threading and Feeding: The leading edge of the coil is threaded through the leveler and into the first roll stand.

- Roll Forming: As the steel progresses through successive stands, the distinctive wave pattern emerges.

- Simultaneous Punching: Servo-punching units create bolt holes according to programmed patterns.

- Continuous Cutting: The flying cut-off system produces exact lengths without stopping production.

- Automatic Stacking: Finished sections are counted and stacked for bundling.

- Packaging and Shipping: Bundles are strapped, labeled, and prepared for transport.

Advanced Features of Modern Machines

Contemporary guardrail forming machines incorporate several technological advancements:

Servo-Driven Punching Systems

Unlike traditional hydraulic systems, servo-electric punches offer:

- Higher precision and repeatability

- Reduced energy consumption

- Faster operation with minimal maintenance

- Programmable patterns for different guardrail types

In-Line Quality Monitoring

Vision systems and laser scanners continuously inspect:

- Profile dimensions

- Hole positioning accuracy

- Surface defects

- Coating integrity (for pre-galvanized material)

Quick-Change Tooling Systems

Advanced machines allow profile changes in under 30 minutes through:

- Cartridge-style roll assemblies

- Pre-set tooling packages

- Automated adjustment systems

Energy Efficiency Features

- Regenerative braking systems on decoilers

- High-efficiency motors with variable frequency drives

- Smart power management during idle periods

Safety and Quality Considerations

Given the critical safety function of guardrails, manufacturing quality is paramount. Modern machines incorporate multiple quality assurance features:

- Real-time thickness monitoring using non-contact sensors

- Automatic defect detection for surface imperfections

- Statistical process control integration

- Complete traceability with data logging for each production run

Manufacturers often customize machines to produce region-specific profiles and hole patterns.

Economic and Operational Benefits

The automation provided by dedicated forming machines offers significant advantages:

Production Efficiency

- High output: A single line can produce 10,000-15,000 meters per shift

- Minimal labor: Typically requires only 2-3 operators

- Reduced waste: Precision forming and cutting minimizes material loss

- Continuous operation: 24/7 production capability with proper maintenance

Quality Advantages

- Consistency: Every section meets exact specifications

- Repeatability: Identical performance across production runs

- Documentation: Automated quality records for compliance

Cost Effectiveness

- Lower per-unit cost compared to manual fabrication

- Reduced scrap rates through precision manufacturing

- Energy efficiency through optimized processes

Maintenance and Longevity

Properly maintained guardrail forming machines have operational lifespans exceeding 20 years. Key maintenance aspects include:

- Regular lubrication of all forming rolls and bearings

- Tooling inspection and refurbishment schedules

- Alignment verification of all roll stands

- Preventive maintenance on hydraulic and electrical systems

- Regular calibration of measurement and control systems

Future Trends and Developments

The guardrail forming industry continues to evolve with several emerging trends:

Smart Manufacturing Integration

- IoT connectivity for remote monitoring and diagnostics

- Predictive maintenance using machine learning algorithms

- Digital twins for virtual machine optimization

- Blockchain technology for supply chain transparency

Advanced Materials Processing

- High-strength steel forming capabilities (up to 700 MPa yield strength)

- Alternative materials such as aluminum and composite-reinforced sections

- In-line coating and surface treatment options

Automation and Robotics

- Automatic coil change systems for uninterrupted production

- Robotic stacking and packaging solutions

- Autonomous guided vehicles for material handling

- AI-powered quality inspection systems

Case Study: Modern Production Facility

A typical state-of-the-art guardrail manufacturing plant might feature:

- Two forming lines with annual capacity of 100,000 tons

- Automated storage for 5,000 steel coils

- Robotic packaging and palletizing systems

- On-site tooling maintenance workshop

- Full laboratory for material testing and quality verification

The highway guardrail forming machine represents a perfect marriage of mechanical engineering and manufacturing technology. It transforms raw steel into precision safety components that protect millions of motorists daily. Through continuous innovation in automation, precision, and efficiency, these machines have evolved from simple forming devices into sophisticated manufacturing systems.

As road safety standards become more stringent and materials technology advances, guardrail forming machines will continue to evolve. Their role in creating reliable, cost-effective safety barriers ensures they remain essential equipment in the global infrastructure landscape. The quiet efficiency of these machines belies their importance—every meter of guardrail produced represents another layer of protection on our highways, safeguarding lives through engineering excellence.

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)