Highway Guardrail Machine: Engineering Safety on the Move

Introduction: The Guardian of the Roadway

Along every mile of modern highway, a silent sentinel stands between motorists and potential catastrophe—the highway guardrail. These steel barriers, scientifically engineered to absorb impact energy and redirect errant vehicles, are fundamental to road safety infrastructure. The specialized equipment that produces these critical safety components is the Highway Guardrail Roll Forming Machine, a robust and highly precise industrial system dedicated to manufacturing the standardized profiles that save lives daily.

What is a Highway Guardrail Machine?

A Highway Guardrail Roll Forming Machine is a heavy-duty, continuous cold roll-forming production line designed explicitly to transform high-strength steel coils into standardized guardrail profiles. Unlike standard roll formers, these machines are built to handle thicker, higher-yield-strength steel (commonly ASTM AASHTO M180 grades) and produce profiles with the exact geometric and mechanical properties required for crashworthiness.

Core Function and Critical Profiles

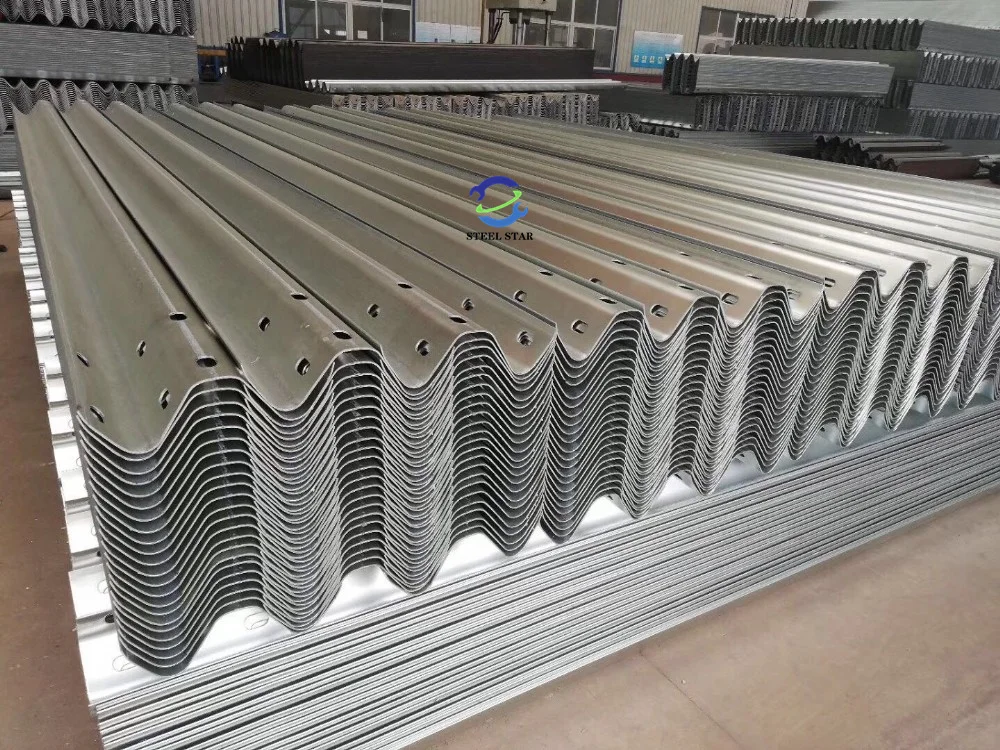

The machine’s primary function is to progressively form thick-gauge steel strip (typically 2.5mm to 4.5mm) into long, consistent guardrail sections without compromising the metal’s structural integrity. The dominant profiles produced are:

- W-Beam (Thrie-Beam): The most common “corrugated” profile. The sinusoidal W-shape is engineered to crumple in a controlled manner upon impact, dissipating kinetic energy and reducing deceleration forces on vehicle occupants.

- Thrie-Beam: A taller, three-wave version of the W-beam used in high-risk areas requiring higher containment capacity, such as medians and sharp curves.

- Post and Blockouts: Complementary components, such as square or I-shaped posts and spacer blocks, can also be produced on auxiliary lines or specific machine configurations.

Anatomy of a Heavy-Duty Production Line

A complete guardrail roll forming system is engineered for strength, precision, and durability:

- Heavy-Duty Decoiler: Built to handle large coils (often 10-20 tons) of high-strength, galvanized steel. Equipped with robust tensioning and edge-guiding systems.

- Pre-Leveling and Feeding: A multi-roller leveler eliminates coil curvature and ensures perfectly flat material entry, which is critical for forming accuracy and profile consistency.

- Roll-Forming Section: The core of the machine. It consists of 12-20 stands of extra-robust, gear-driven forming stations. The rollers are made from premium alloy steel and are meticulously machined to gradually bend the tough steel into the precise corrugated shape. High mechanical rigidity is essential to prevent deflection under the extreme forming pressure.

- In-Line Punching/Hole-Pattern Unit: A critical station that uses high-tonnage hydraulic punches to create the precise bolt hole patterns at regular intervals along the flat strip before final forming. This ensures perfect hole alignment for on-site assembly.

- Cut-Off System: A powerful hydraulic flying cut-off or a heavy-duty cuts the continuously moving guardrail to standard lengths (typically 3.8m, 7.6m, or 12.2m / 12.5ft, 25ft, or 40ft) without stopping the line.

- Run-Out & Stacking: A reinforced run-out table supports the heavy product, leading to an automatic stacker that organizes the guardrails into secure bundles for transport.

- Advanced Control System: A ruggedized PLC with an HMI oversees the entire process. It manages speed synchronization, punch timing, cut length, and monitors system health, ensuring every section meets specification.

Key Technological and Safety Features

- Extreme Durability: Constructed with heavy-section frames, large-diameter shafts, and high-capacity bearings to withstand the immense forces required to form thick, high-strength steel.

- Precision Hole Punching: In-line servo-controlled punching guarantees absolute accuracy in bolt hole placement, which is vital for the structural integrity of the installed guardrail system.

- Consistency is Critical: The machine must produce profiles with unwavering dimensional consistency to ensure predictable, certified crash performance. Even minor variations can affect safety outcomes.

- High-Throughput Design: Engineered for continuous, reliable operation to meet the large-volume demands of national highway and infrastructure projects.

- Galvanization-Friendly Design: The forming process is designed to work with pre-galvanized coils without causing excessive coating damage, maintaining corrosion resistance.

Impact on Transportation Safety and Infrastructure

The highway guardrail machine is a direct contributor to public safety:

- Enabling Mass Safety Infrastructure: It makes the cost-effective, large-scale production of certified safety barriers possible, allowing for widespread deployment on road networks.

- Supporting Standards Compliance: It is the essential tool for manufacturers to produce components that comply with rigorous governmental safety testing and standards.

- Facilitating Rapid Deployment: Efficient production supports the quick installation and replacement of barriers in construction zones and on existing highways, enhancing overall road safety management.

The Highway Guardrail Roll Forming Machine is more than industrial equipment; it is a pivotal technology in the chain of road safety. By combining brute mechanical force with precise engineering control, it transforms raw steel into a life-saving device with unwavering reliability. As vehicle technology and traffic patterns evolve, the demand for even more advanced barrier systems will grow. The machines that produce them will continue to advance in tandem, incorporating smarter controls and more sophisticated forming techniques to meet future safety challenges. In the end, this machine’s true product is not just steel, but confidence—the confidence that our roadways are guarded by a robust, scientifically engineered line of defense.

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)