Hydraulic Shearing Machine Price: A Comprehensive Breakdown

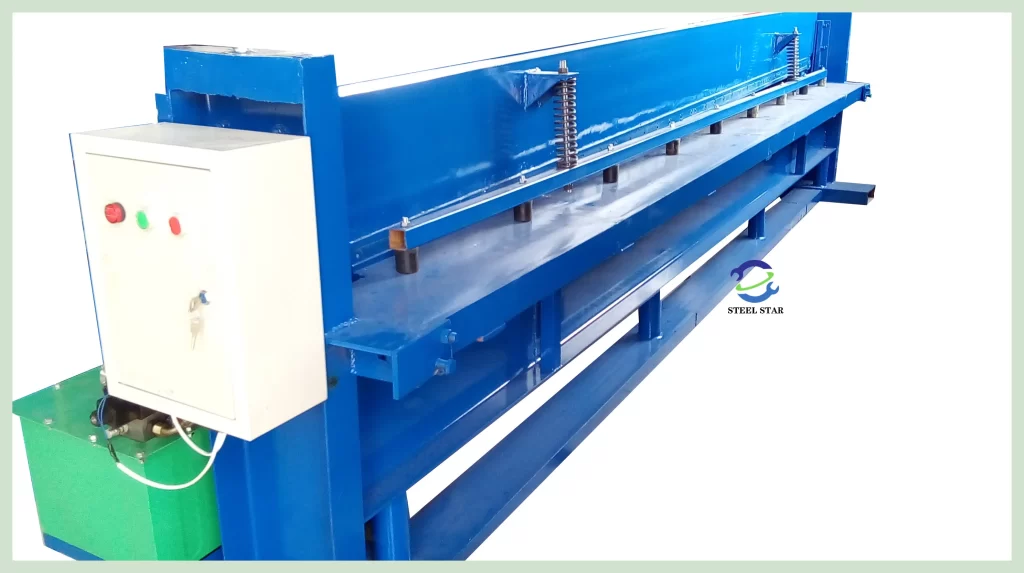

A hydraulic shearing machine is a cornerstone piece of equipment in metal fabrication, workshops, and manufacturing plants. It utilizes hydraulic power to deliver the force required for cleanly and precisely cutting sheet metal. When considering an investment, understanding the factors that influence the hydraulic shearing machine price is crucial for making a cost-effective and suitable purchase. Prices are not arbitrary; they reflect a combination of machine capability, build quality, and features.

This guide provides a detailed analysis of the price structure, helping you navigate the market from entry-level models to industrial-grade powerhouses.

Price Range Overview

Hydraulic shearing machine prices vary dramatically based on specifications. Here is a general market overview:

- Entry-Level / Small Capacity Machines: For bench-top or small standalone machines with capacities up to 4mm (mild steel, 1m length), prices typically range from $3,000 to $12,000. These are suitable for workshops, garages, and light fabrication.

- Mid-Range / Standard Industrial Machines: The most common category for fabrication shops. Machines with capacities from 6mm to 12mm (mild steel, 2m-4m length) generally fall between $15,000 and $50,000. This range offers robust performance and essential features.

- High-End / Heavy-Duty & CNC Machines: For large-scale industrial production, machines with capacities over 12mm, lengths over 4m, or equipped with full CNC (Computer Numerical Control) back gauges, automatic sheet followers, and sophisticated software can range from $60,000 to well over $200,000.

Key Factors Determining the Price

- Cutting Capacity & Machine Size: This is the primary cost driver.

- Material Thickness: A machine rated for 6mm mild steel costs significantly less than one rated for 20mm.

- Cutting Length: Standard lengths are 2m, 2.5m, 3m, and 4m. Longer beds increase the price.

- Material Type: Capacity is usually stated for mild steel (A3). Cutting stainless steel or high-strength alloys requires a machine with higher tonnage, impacting cost.

- Construction Quality & Components:

- Frame: A heavy, welded steel frame ensures stability and accuracy under load. Lighter frames reduce cost but compromise performance and longevity.

- Hydraulic System: The quality of the pump, valves, cylinders, and seals is critical. Reputable brands (e.g., Bosch Rexroth, Parker) add to the cost but ensure reliability and consistent power.

- Blades: Standard tool steel blades are common. Durable, long-life blades (e.g., T10, Cr12MoV) or specialized blades for specific materials cost more.

- Control System & Features:

- Basic Models: Feature manual back gauges and simple foot-pedal operation.

- Mid-Range Models: Include a Digital Read Out (DRO) for the back gauge, rapid blade gap adjustment, and hydraulic hold-downs.

- Premium/CNC Models: Feature a full CNC back gauge with motorized axis control, programmable cutting sequences, automatic sheet support arms, and touch-screen interfaces. This automation greatly enhances precision and repeatability, adding substantially to the price.

- Additional Costs (Beyond the Sticker Price):

- Shipping & Rigging: Large, heavy machines incur significant shipping and installation costs.

- Tooling & Spares: A set of spare blades is a necessary additional expense.

- Training & Maintenance: Factor in potential costs for operator training and a planned maintenance schedule.

- Electrical Requirements: Ensuring your facility has the correct power supply (3-phase is common) may involve upgrade costs.

Price vs. Value: Strategic Considerations

- Assess Your Real Needs: Don’t overbuy. A 6mm x 2.5m machine may suffice if you rarely cut 10mm plate. Consider your most common material and maximum required length.

- Total Cost of Ownership (TCO): A cheaper machine with poor components may lead to higher downtime, maintenance costs, and inferior cut quality, ultimately costing more over its lifespan.

- Resale Value: Machines from recognized brands with good service records typically retain higher resale value.

- Supplier Support: A reliable supplier offering installation, training, warranty, and ready access to technical support and spare parts is invaluable and justifies a higher initial investment.

The price of a hydraulic shearing machine is a direct reflection of its capability, durability, and technological sophistication. While initial budget is important, the decision should be guided by a thorough analysis of your specific cutting requirements, desired features, and the long-term value offered by the machine’s construction and brand support. Investing time in defining your needs and researching reputable suppliers will ensure you purchase a machine that delivers optimal performance and return on investment for years to come, making it a true asset to your operation rather than just a cost.

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)