Light Gauge Steel Framing Machines: Revolutionizing Modern Construction

For over a century, dimensional lumber has been the dominant structural skeleton for residential and low-rise commercial buildings. However, this material faces increasing challenges: variability in quality, susceptibility to moisture and pests, price volatility, and sustainability concerns related to forestry. In response, a technologically advanced alternative has risen to prominence, fundamentally changing how buildings are conceived and assembled: Light Gauge Steel Framing (LGSF).

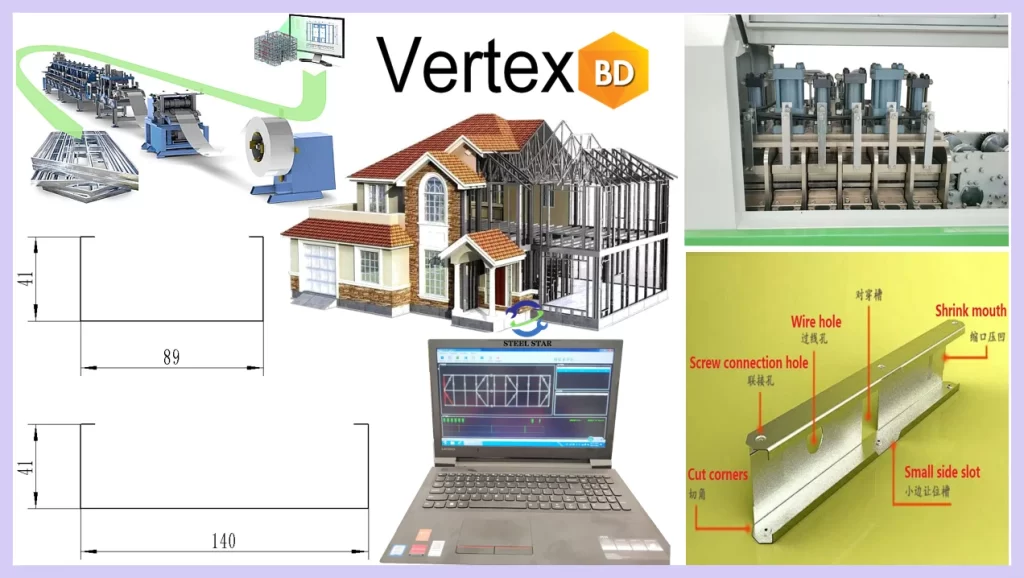

At the core of this construction revolution is a remarkable piece of industrial engineering: the Light Gauge Steel Frame Machine. This is not a single machine, but a highly automated production system that transforms coils of thin, high-strength steel into precise, code-compliant structural components—studs, tracks, joists, rafters, and complex trusses—with unparalleled speed, accuracy, and efficiency. This article delves into the technology, process, components, and profound impact of these machines on the global construction industry.

Part 1: Understanding Light Gauge Steel Framing (LGSF)

Before examining the machines, one must understand the product. LGSF, also known as cold-formed steel (CFS) framing, utilizes galvanized steel sheets typically ranging from 0.7 mm to 2.0 mm (20 to 12 gauge) in thickness. These sheets are cold-rolled into C-shaped studs, U-shaped tracks, and other profiles.

Key Advantages of LGSF:

- Strength & Durability: High strength-to-weight ratio, non-combustible, impervious to termites, rot, and warping.

- Dimensional Stability: Does not shrink, swell, or twist like wood, ensuring straight, true walls.

- Precision & Consistency: Factory-made components result in less on-site waste and predictable performance.

- Sustainability: Made from recycled steel and is 100% recyclable at end of life. Creates less job-site waste.

- Speed of Construction: Panels and trusses can be pre-fabricated off-site for rapid assembly.

The enabler of all these advantages is the precision and automation of the framing machine.

Part 2: Anatomy of a Light Gauge Steel Frame Machine

A modern LGSF production line is a symphony of integrated machinery. The process follows a logical flow from raw material to finished component.

1. Decoiling & Straightening:

The process begins with a massive coil of galvanized steel. An automatic decoiler holds and feeds the coil into a leveling and straightening unit. This critical step removes any coil set or camber, ensuring the steel strip is perfectly flat before forming.

2. The Roll Forming Mill: The Heart of the System

This is where the flat strip is transformed. The steel is fed through a progressive series of roll forming stations. Each station features a set of precision-machined, hardened steel rollers that incrementally bend the metal into the desired cross-sectional shape (e.g., a C-stud with flanges and returns). Modern mills are servo-driven, allowing for exceptional control over speed and synchronization. The key here is cold working; the steel gains strength as it is plastically deformed at room temperature.

3. Punching & Notching Unit:

Integrated within or immediately after the roll former is a high-tonnage, CNC-controlled punching press. This unit performs a variety of operations in a single hit:

- Punching Service Holes: Creates pre-engineered openings for electrical wiring, plumbing, and HVAC ducts.

- End Notching: Cuts out sections at the ends of studs to allow for track fitting or lapping.

- Slots and Cut-Outs: For bracing, connectors, or other integrations.

The precision of this CNC punch is what allows for the “plug-and-play” assembly of LGSF, as all holes align perfectly in the finished structure.

4. Cut-Off System:

A flying cut-off mechanism—hydraulic, servo, or shear-type—cleanly cuts the continuously moving formed profile to exact, programmed lengths. Advanced systems can vary lengths on-the-fly for a batch of customized components.

5. Automatic Stacking & Bundling:

Finished components are automatically conveyed, counted, aligned, and stacked into neat bundles. These bundles are then strapped, labeled with job information, and prepared for shipment to the construction site or a panel fabrication shop.

6. The Brains: Industrial Computer & Software

The entire line is governed by a sophisticated PLC (Programmable Logic Controller) and HMI (Human-Machine Interface). Operators input parameters (profile type, length, hole pattern, quantity) into specialized software. This software not only runs the machine but also often integrates with Building Information Modeling (BIM) systems. A 3D BIM model can directly generate the machine code (G-code or proprietary language), ensuring the physical components are a perfect match for the digital design.

Part 3: Types of Machines and Advanced Systems

Beyond basic stud-and-track lines, specialized machines cater to different aspects of LGSF construction:

- Truss Fabrication Machines: These are highly complex systems that can form, punch, cut, and assemble individual truss members (top chords, bottom chords, webs) and then weld or screw-connect them into complete roof or floor trusses automatically.

- Panel Framing Lines: The next level of automation. These lines take formed studs and tracks, automatically space and fasten the studs into the tracks using screwdrivers or welders, creating complete wall, floor, or roof panels. They can even integrate sheathing (OSB, gypsum) application.

- High-Speed, High-Volume Stud Machines: Dedicated lines for mass-producing standard studs for large-scale projects like hotels, apartments, and hospitals.

- Custom Profile Roll Formers: For creating specialized components like curved track, jamb studs, or proprietary connector profiles.

Part 4: The Impact on the Construction Industry

The adoption of LGSF machines drives profound changes across the sector:

1. The Rise of Off-Site Construction (Prefabrication):

These machines are the engine of the modular and panelized construction revolution. Components or entire wall/floor/roof panels can be manufactured in a controlled factory environment year-round, unaffected by weather. This reduces on-site construction time by 30-50%, a critical advantage.

2. Unprecedented Precision and Quality Control:

Factory tolerances are measured in millimeters, compared to the centimeter-level tolerances common in stick-built construction. This precision facilitates the integration of other building systems (MEP) and improves the overall quality and performance of the building envelope.

3. Labor and Safety Dynamics:

While the machines require skilled technicians and programmers, they reduce the demand for highly skilled carpenters on-site. Assembly becomes more like a mechanical process, which can help address labor shortages. Factory settings are also statistically safer than construction sites, reducing the risk of falls and other accidents.

4. Sustainability and Waste Reduction:

Steel is the world’s most recycled material. LGSF production generates minimal scrap (often less than 2%), and any scrap is 100% recyclable. This contrasts sharply with the significant waste generated by traditional wood framing.

5. Design Flexibility:

The strength of steel allows for longer spans and more open floor plans. BIM integration allows architects and engineers to design complex structures with the confidence that the fabrication data will translate perfectly to the factory floor.

Part 5: Challenges and Future Directions

The technology is not without its challenges and areas for evolution:

- High Initial Investment: A complete, advanced LGSF production line represents a major capital expenditure, creating a barrier to entry for smaller fabricators.

- Thermal Bridging: Steel is an excellent conductor of heat, requiring careful detailing and the use of thermal breaks (e.g., insulated sheathing, thermal strips) to meet modern energy codes. This is a building science challenge, not a machine limitation.

- Skilled Labor Shift: The industry needs more software-literate machine operators, technicians, and detailers, shifting the skill set from traditional trades.

- Future Trends: The future lies in deeper AI and IoT integration (predictive maintenance, real-time optimization), increased robotics for material handling and assembly, and the development of machines that can work with new materials like high-strength, lightweight alloys or composite-faced panels.

The Light Gauge Steel Frame Machine is far more than a large tool. It is the physical manifestation of a paradigm shift in construction—from a craft-based, on-site, variable process to a manufacturing-based, off-site, controlled and repeatable one. By marrying the timeless strength of steel with the precision of modern CNC robotics and digital design, these machines are producing the skeletons for the next generation of durable, efficient, and resilient buildings.

They empower architects to design with greater freedom, help builders deliver projects faster and with less risk, and contribute to a more sustainable built environment. As urbanization accelerates and the demand for quality housing and infrastructure grows globally, the role of the light gauge steel framing machine will only become more central, quietly and efficiently building the future, one perfectly formed stud at a time.

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)