The Light Gauge Steel Framing Machine: Revolutionizing Modern Construction

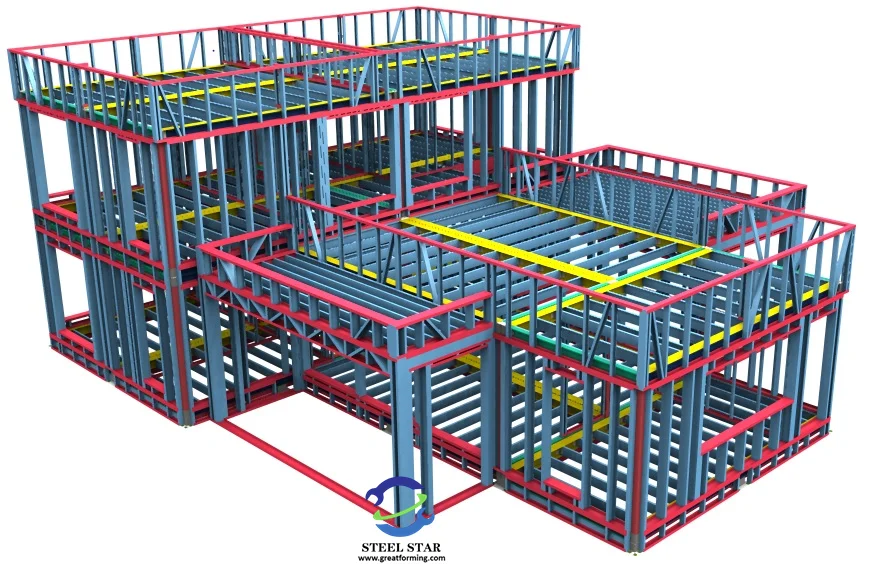

In an era demanding faster, stronger, and more sustainable building solutions, Light Gauge Steel Framing (LGSF) has emerged as a transformative technology. At the heart of this construction revolution lies a sophisticated piece of equipment: the Light Gauge Steel Framing Machine. This machinery automates the conversion of raw steel coils into precise, high-strength structural components, forming the skeleton of modern residential, commercial, and industrial buildings.

What is a Light Gauge Steel Framing Machine?

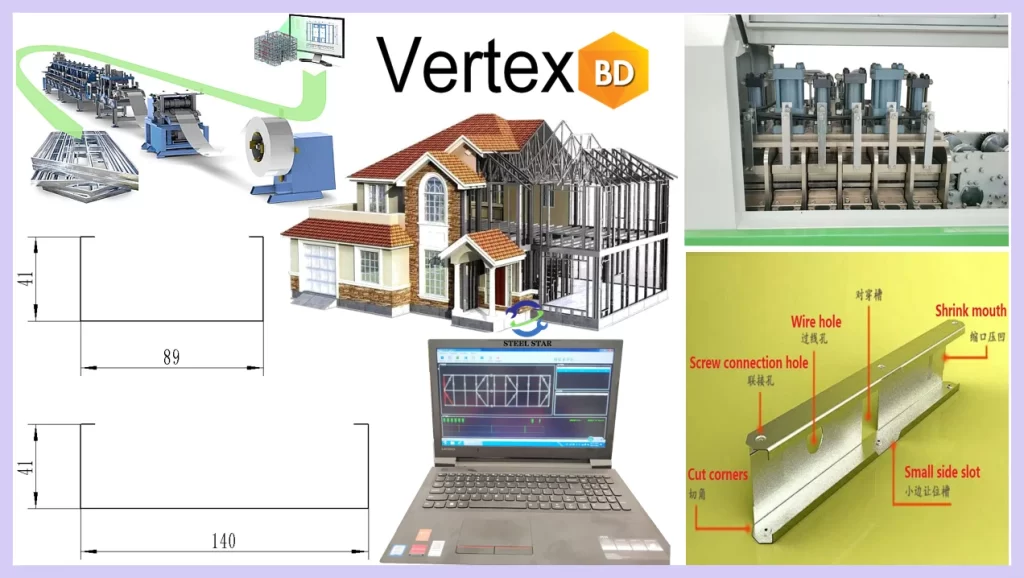

A Light Gauge Steel Framing Machine is a highly automated roll forming production line specifically engineered to fabricate cold-formed steel (CFS) studs, tracks, joists, and other framing members from galvanized or galvalume steel coils. Unlike hot-rolled steel, light gauge steel is formed at room temperature, resulting in components that are lightweight yet exceptionally strong, non-combustible, and dimensionally stable.

Core Components and Workflow

A typical advanced framing line integrates several key stations into a seamless process:

- Decoiler & Straightener: The process begins with a heavy-duty decoiler that holds the master steel coil (typically 0.5mm to 2.0mm in thickness). An integrated leveling unit then removes any coil curvature or imperfections, ensuring perfectly flat sheet entry.

- Pre-Punching/Notching Station: This critical CNC-controlled unit punches out service holes (for electrical, plumbing), web holes for weight reduction, and end notches for connectors or nesting. Precision here is vital for on-site assembly speed and utility integration.

- The Roll Forming Mill: The heart of the machine. A series of computer-designed roll stations progressively bend the flat, punched metal strip into the desired C-shaped (stud), U-shaped (track), or other complex open or closed sections. The number of forming stands determines the profile complexity and forming precision.

- Cut-Off System: A high-speed, servo-controlled flying cut system accurately shears the continuously formed profile to pre-set lengths (e.g., standard wall stud heights) without stopping the line, ensuring high productivity and clean, burr-free cuts.

- Automatic Stacking & Bundling: The finished components are automatically counted, aligned, and stacked into neat bundles, often strapped for easy handling, shipping, and direct delivery to the construction site.

Types of Machines and Output

Machines range from dedicated single-profile lines (high-speed production of standard studs/tracks) to flexible modular lines that can produce a wide variety of profiles (e.g., ceiling joists, floor joists, furring channels) with quick tooling changes. The most advanced systems are fully automated, robotic-assisted framing lines that can fabricate and even pre-assemble entire wall panels, trusses, or floor cassettes based on digital BIM (Building Information Modeling) data.

Key Advantages Driving Adoption

- Unrivaled Speed & Efficiency: Machines can produce a complete house frame in days versus weeks, drastically shortening project timelines and reducing labor costs.

- Extreme Precision & Consistency: Every component is manufactured to tolerances within ±0.5mm, eliminating the variability, warping, and shrinkage associated with traditional wood framing. This precision ensures perfect fit during assembly.

- Material Strength & Sustainability: Steel is 100% recyclable, resistant to termites, rot, and fire. The cold-forming process enhances its strength, allowing for longer spans and innovative designs.

- Reduced Waste: Precision manufacturing from coiled steel generates minimal on-site waste (<2%), contributing to cleaner job sites and lower material costs.

- Design Flexibility: Enables complex architectural designs and easy integration with other building systems. Compatible with all common cladding and insulation materials.

Considerations for Manufacturers & Builders

Investing in or utilizing output from LGSF machinery requires an understanding of:

- Profile Library: The range of sections a machine can produce determines its versatility.

- Material Grade & Coating: Typically, G550 or higher yield strength steel with AZ150 (150g/sqm) galvanization for corrosion resistance.

- Integration with Design Software: The true power is unlocked when the machine is driven directly by CAD/CAM or BIM software, enabling a seamless digital workflow from design to fabrication.

The Light Gauge Steel Framing Machine is more than industrial equipment; it is the catalyst for a paradigm shift in construction. By marrying digital design with automated, precise manufacturing, it delivers a building system that is faster, stronger, greener, and smarter. As the global construction industry seeks solutions to housing shortages, labor challenges, and climate goals, LGSF technology, powered by these advanced machines, is poised to frame the future of the built environment. It represents not just an alternative to traditional methods, but a significant step forward in the evolution of how we build.

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)