The Rise of Light Gauge Steel Framing Machines: Revolutionizing Modern Construction

The construction industry, long characterized by manual labor and traditional materials, is undergoing a significant transformation. At the forefront of this shift is the increasing adoption of Light Gauge Steel Framing (LGSF) machines—automated systems that produce steel frames for residential, commercial, and industrial buildings. These machines represent a convergence of precision engineering, digital fabrication, and sustainable building practices, offering a compelling alternative to conventional wood framing.

What Are Light Gauge Steel Framing Machines?

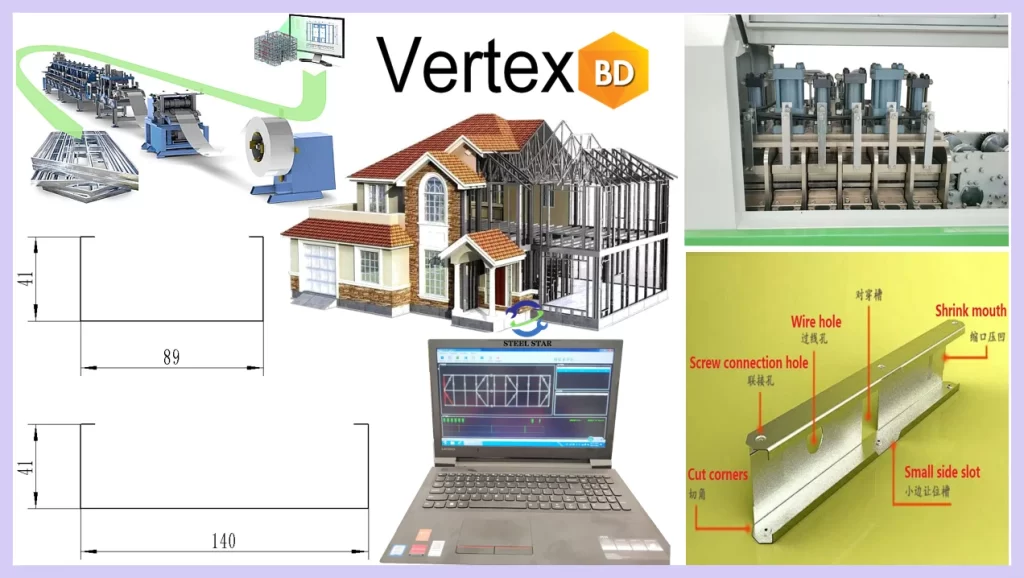

Light Gauge Steel Framing machines are roll-forming systems that convert galvanized steel coils into structural components such as studs, tracks, joists, and trusses. The process begins with a coil of high-strength, zinc-coated steel, typically ranging from 0.5 mm to 2.5 mm in thickness. The coil is fed through a series of rollers that gradually shape the flat steel into C-sections, Z-sections, or custom profiles. Punches and notches are added along the length to accommodate electrical wiring, plumbing, and fasteners—all in a single continuous operation.

Modern LGSF machines are CNC-controlled, meaning they operate directly from digital design files. This integration with Building Information Modeling (BIM) software allows for seamless translation of architectural drawings into finished components. Operators can adjust dimensions, hole patterns, and cut lengths in real time, enabling mass customization without slowing production.

Advantages Over Traditional Framing

The shift from wood to steel framing is driven by several distinct advantages, many of which are amplified by the automation of LGSF machines.

Precision and Consistency – Manual framing is subject to human error. Measurements can be off by centimeters; cuts may not be perfectly square. LGSF machines, by contrast, produce components with tolerances measured in fractions of a millimeter. Every stud is identical to the last, ensuring that walls are straight, corners are square, and assemblies fit together as intended.

Speed of Construction – A roll-forming machine can produce framing for an entire house in a single day. Once delivered to the site, the components are lightweight and color-coded for quick assembly. Builders report reductions in framing time of 30% to 50% compared to wood. This speed translates directly into lower labor costs and faster project turnover.

Material Efficiency – Steel coils are continuous, and modern machines are programmed to nest cuts in a way that minimizes waste. Scrap rates for LGSF production are typically below 5%, compared to 20% or more for dimensional lumber. Moreover, steel is 100% recyclable, and most framing steel contains significant recycled content.

Durability and Performance – Steel does not warp, shrink, split, or rot. It is impervious to termites and other wood-boring insects. In fire testing, light gauge steel framing has demonstrated superior performance compared to wood, retaining structural integrity longer under high temperatures. For builders in seismic or high-wind regions, steel’s strength-to-weight ratio and ductility offer additional safety margins.

Applications Across Building Types

While LGSF has long been associated with commercial curtain walls and interior partitions, the technology has matured to support full building envelopes. In the residential sector, entire subdivisions are now being built with steel framing, particularly in markets where timber is expensive or prone to termite damage. Multifamily housing, hotels, and student dormitories benefit from the speed and fire resistance of steel-framed pods manufactured off-site. Industrial applications include mezzanines, racking systems, and equipment shelters.

The synergy between LGSF machines and modular construction is especially promising. Steel-framed panels and modules can be prefabricated in climate-controlled factories, shipped to site, and erected in days. This hybrid model—part factory production, part field assembly—is gaining traction as developers seek to mitigate weather delays and skilled labor shortages.

Economic Considerations

The primary barrier to entry for LGSF is capital cost. A high-capacity, multi-profile roll-forming line represents a significant investment, typically ranging from $150,000 for entry-level machines to over $500,000 for fully automated systems with integrated software and material handling. However, for established framing contractors, steel fabricators, and building material suppliers, the return on investment can be compelling.

Profitability depends largely on volume. A machine operating at 20 to 30 meters per minute can easily outproduce a crew of carpenters, and the margins on fabricated steel components are substantially higher than on raw lumber or steel coil. As timber prices have become increasingly volatile, the predictable cost structure of steel has become an additional financial advantage.

The Role of Software and Training

It is a common misconception that LGSF machines are simply hardware. In practice, the software is equally critical. Advanced nesting algorithms optimize material usage; structural validation tools check that components meet load requirements; and production scheduling modules sequence jobs to minimize changeover time.

This digital dependency introduces a training gap. Traditional framers understand carpentry but may not be fluent in CAD or BIM. Conversely, recent graduates with digital skills may lack construction site experience. Successful LGSF operations invest heavily in cross-training, teaching machinists to read architectural intent and teaching designers to understand production constraints.

Global Market Trends

The adoption of LGSF varies significantly by region. In North America, wood remains dominant for residential construction, but steel is gaining market share in wildfire-prone areas and among builders pursuing green certifications. Australia, facing timber shortages and termite pressures, has embraced steel framing for decades, with a mature ecosystem of local machine manufacturers and fabricators. Europe, particularly Germany and Italy, has been at the forefront of machine innovation, producing high-speed lines with sophisticated servo-electric controls.

Emerging markets present the most dramatic growth. In India, China, and Southeast Asia, rapid urbanization and government interest in prefabricated construction have fueled demand for LGSF technology. Developers in these regions are leapfrogging conventional building methods and adopting automated framing as a primary construction system.

Challenges and Limitations

Despite its advantages, LGSF is not a universal solution. Thermal bridging—the conduction of heat through steel members—requires careful detailing and continuous insulation to meet energy codes. Acoustic performance in multi-story buildings often necessitates additional sound-damping treatments. And while steel framing is lighter than concrete or masonry, it is heavier than wood, which can influence logistics and crane requirements.

Furthermore, the industry faces a perception hurdle. In some markets, steel framing is still viewed as a commercial or industrial product, not a residential one. Builders accustomed to wood may be reluctant to retrain crews or invest in new fastening systems. Overcoming this inertia requires both education and demonstrated project success.

The Future of LGSF

The trajectory of light gauge steel framing is clear: more automation, tighter integration with design, and broader adoption across building types. Emerging developments include hybrid machines that can switch between profiles without manual tooling changes, on-site mobile factories that produce framing at the construction perimeter, and artificial intelligence that predicts maintenance needs and optimizes cutting patterns.

As the construction industry confronts rising material costs, labor shortages, and pressure to reduce its environmental footprint, the case for automated steel framing grows stronger. The machines themselves are becoming faster and more intelligent. But the real transformation is in how we think about building—not as a series of field trades, but as a manufacturing process in which the building is the product.

Light gauge steel framing machines are no longer a niche tool for specialized fabricators. They are becoming a cornerstone of modern construction, enabling structures that are stronger, straighter, and built in a fraction of the time. For contractors and developers willing to embrace the technology, the framing of the future is already here.

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)