The Light Gauge Steel Roll Forming Machine: Engine of Modern Construction

The shift towards efficient, sustainable, and resilient building methods has propelled Light Gauge Steel (LGS) framing to the forefront of modern construction. At the core of this revolution lies a pivotal piece of industrial equipment: the Light Gauge Steel Roll Forming Machine. This highly specialized machinery is the production engine for the cold-formed steel studs, tracks, joists, and panels that form the skeletons of everything from residential homes and mid-rise apartments to commercial interiors and industrial facilities.

Core Function and Principle

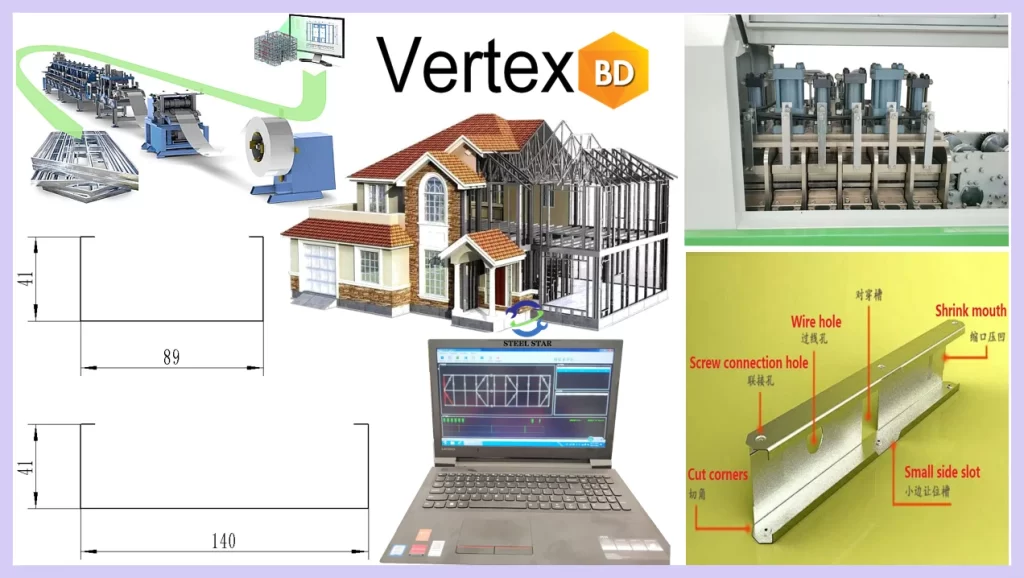

A Light Gauge Steel Roll Forming Machine is a cold roll forming system designed to process thin-gauge, high-strength steel coils—typically ranging from 0.5mm to 2.0mm (20 to 12 gauge) in thickness—into precise, long-length structural components. Unlike hot-rolled steel, LGS is formed at room temperature, which work-hardens the steel, enhancing its strength. The machine’s fundamental principle is continuous, incremental deformation. A flat steel strip is progressively shaped by a series of roller dies, each performing a small bend until the final, complex cross-section is achieved. This method allows for the creation of optimized profiles with high dimensional accuracy and repeatability.

Key Components and Process Stages

A complete LGS roll forming line is an integrated system comprising several key stations:

- Uncoiling & Leveling: The process begins with a decoiler holding the master coil of galvanized or Galvalume steel. The strip is fed into a precision leveler, which removes any coil curvature or internal stresses, ensuring perfectly flat material enters the forming process.

- Pre-Punching/Notching Unit (Critical for Studs/Tracks): This is a defining feature of framing machinery. Before the strip is formed, a servo-driven punching station precisely cuts web holes (for utility routing, weight reduction, and fire-stop mortar passage) and notches the flanges at predetermined intervals. These features are crucial for building code compliance and on-site assembly efficiency.

- The Roll Forming Mill: The heart of the machine. Here, the pre-punched strip passes through a series of roll stands (often 18-30 stations) mounted on a rigid frame. Each set of contoured, hardened steel rollers performs a precise, incremental bend. The profile is gradually transformed from flat strip into a final shape, such as a C-stud (with lips and returns for strength) or a U-track.

- Cut-off System: As the fully formed profile exits the final stand, a precise, servo-controlled flying cut-off system (usually a hydraulic shear or high-speed saw) cuts the continuous member to exact, programmable lengths without stopping the line.

- Run-out Table & Stacker: The cut-to-length pieces are conveyed, automatically sorted (e.g., studs vs. tracks), and stacked into bundles for strapping and shipment.

Technical Advantages and Design Considerations

The roll forming process is uniquely suited for LGS framing production, offering decisive advantages:

- High-Speed Mass Production: Enables the rapid, continuous output required for large-scale projects, dramatically outpacing traditional stick-framing or manual fabrication.

- Exceptional Consistency and Precision: Every component is geometrically identical, ensuring predictable structural performance, ease of design, and swift, error-free on-site assembly. This precision is foundational for panelized and modular construction.

- Material Efficiency and Strength: The process generates almost no material waste. The cold-forming increases yield strength at the bends, and the profiles themselves are engineered for optimal strength-to-weight ratio.

- Unmatched Flexibility: Advanced machines offer quick-change roll systems and servo-driven punch units, allowing a single line to produce dozens of different profiles (studs, tracks, joists, hat channels) and lengths on demand from a single material coil.

Machine design emphasizes extreme rigidity to maintain tolerance under high forming loads. The synchronization between the servo-punching unit and the flying cut-off is controlled by sophisticated software, ensuring hole and notch patterns are perfectly located on the final part, regardless of cut length.

Integration and Technological Evolution

Modern LGS roll forming lines are highly automated manufacturing cells. They are governed by PC-based controls with graphical HMIs, allowing operators to select part profiles and lengths from a recipe library. Integration with Building Information Modeling (BIM) software is the new frontier, where design files can directly generate machine instructions, driving the trend towards full construction digitalization. Many lines now incorporate automatic bundle strapping and labeling, moving the industry closer to a true “lights-out” factory model.

The Light Gauge Steel Roll Forming Machine is far more than a simple fabricator; it is the linchpin of a transformative construction methodology. By enabling the fast, precise, and waste-efficient production of structural components, it directly supports the goals of speed, sustainability, and resilience that define contemporary building. As the demand for efficient, non-combustible, and recyclable building systems grows, this machine—and the continuous innovation behind it—will remain central to shaping the future of the built environment, one precisely formed steel member at a time.

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)