Light Keel Roll Forming Machine: The Backbone of Modern Drywall Construction

The Light Keel Roll Forming Machine is a specialized piece of manufacturing equipment designed to produce the fundamental metal framing components—studs, tracks, and runners—used in modern drywall partition and ceiling systems. This machine is the industrial engine behind the lightweight, strong, and precisely engineered steel skeleton that defines contemporary interior construction.

Core Function and Product Output

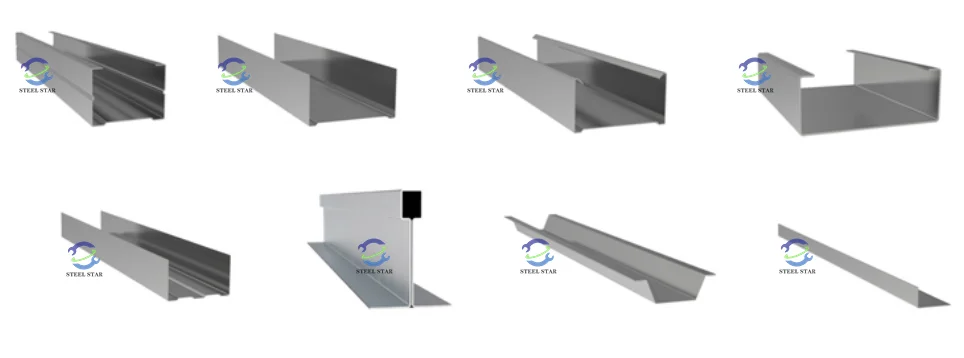

The machine automates the high-volume production of cold-formed steel profiles, commonly known as light gauge steel framing. Starting from coils of galvanized steel strip, it performs a continuous roll forming process to create standardized C-shaped studs, U-shaped tracks, and other specialized profiles like furring channels. These components are characterized by their thin webs and return lips, which provide optimal strength-to-weight ratios for non-load bearing walls and ceilings.

Integrated Production Line Components

A complete light keel production line is a synchronized system:

- Decoiler & Straightener: Holds the steel coil and feeds it into the line, ensuring the material is flat and free of coil curvature.

- Pre-Punching/Notching Station (Servo or Hydraulic): A critical feature. This unit punches out pre-set holes in the flat strip for utility runs (electrical, plumbing) and creates the precise notches at the ends of studs that allow for cross-member (channel) connection. Modern servo-driven units offer high flexibility for pattern changes.

- Roll Forming Mainframe: The machine’s core, comprising a series of roller dies that progressively bend the pre-punched flat strip into the final profile (e.g., 50mm, 75mm, 100mm C-section). Precision tooling ensures consistent cross-sectional geometry.

- Cut-Off System: A high-speed, hydraulic or servo-driven flying cut shears the continuously formed profile to exact lengths (commonly 2400mm to 6000mm) without stopping production.

- Output & Stacking System: Automatically conveys and stacks the finished studs or tracks into bundles for strapping and shipment.

Key Advantages and Industry Impact

- Unmatched Speed and Volume: Capable of producing hundreds of meters of framing per hour, meeting the high-volume demands of large-scale construction projects.

- Precision and Consistency: Every stud and track is identical, ensuring predictable performance, ease of assembly on-site, and perfect alignment for drywall installation. This eliminates the variability and warping associated with traditional timber framing.

- Material Efficiency and Sustainability: Minimizes steel waste through precise pre-punching and cutting. The use of galvanized steel also provides inherent resistance to rot, mold, and pests, contributing to a longer-lasting, more sustainable building envelope.

- Design Flexibility: Quick tooling changes allow a single machine to produce a wide range of profiles and sizes, adapting to different architectural specifications and building codes.

- Labor and Cost Optimization: Automates a labor-intensive fabrication process, reducing on-site cutting, drilling, and waste handling.

Technological Drivers

- CNC and Servo Technology: Advanced Computer Numerical Control (CNC) for punch patterns and servo-driven cut-off systems enable rapid changeovers, complex hole patterns, and extreme length accuracy.

- Programmable Logic Control (PLC): Manages the entire synchronized process, stores product recipes, and provides diagnostic monitoring for minimal downtime.

- High-Strength Steel Compatibility: Engineered to form higher yield strength steels (e.g., G550), allowing for lighter, stronger frames that improve structural performance.

Application in Modern Construction

The components produced are essential for:

- Commercial Interiors: Office partitions, retail spaces, hospitals.

- Residential Construction: Interior walls in multi-family units (apartments, hotels).

- Ceiling Systems: Suspended grid frameworks for acoustical and decorative ceilings.

The machine directly supports faster, drier, and more precise construction methodologies, aligning with lean construction principles and quality-focused building practices.

The Light Keel Roll Forming Machine is more than a fabricator; it is a critical enabler of modern light steel frame construction. By delivering standardized, high-quality, and cost-effective framing components with industrial efficiency, it has revolutionized interior building systems. As the construction industry continues to prioritize speed, precision, and sustainable materials, this machine remains a pivotal technology in shaping the adaptable and resilient interior spaces of the future.

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)