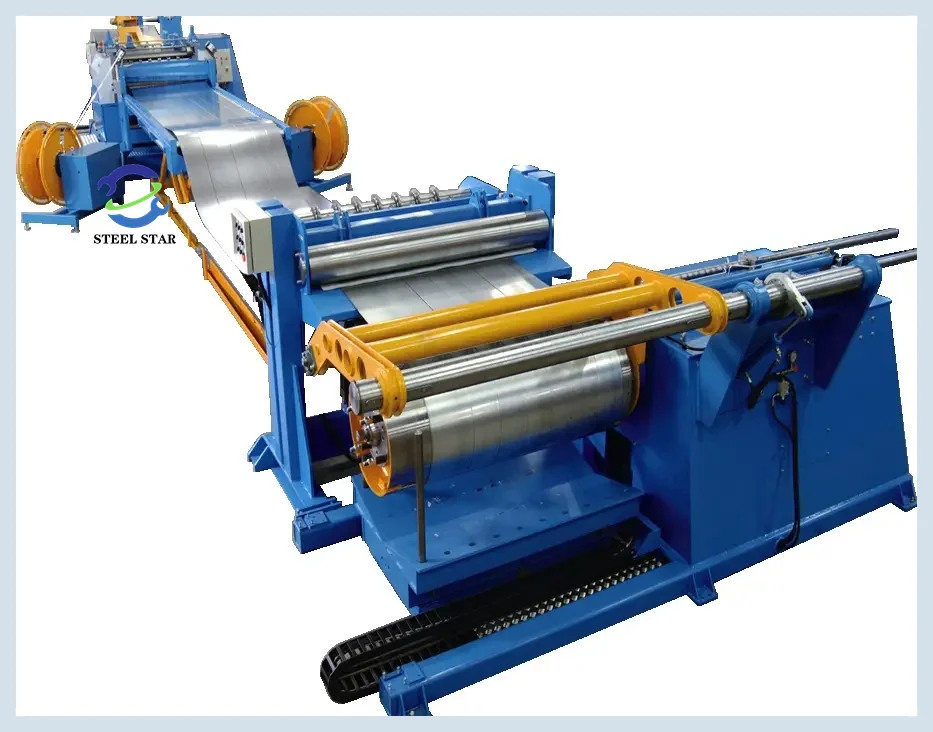

Metal Coil Slitting Machine: The Precision Heart of Material Processing

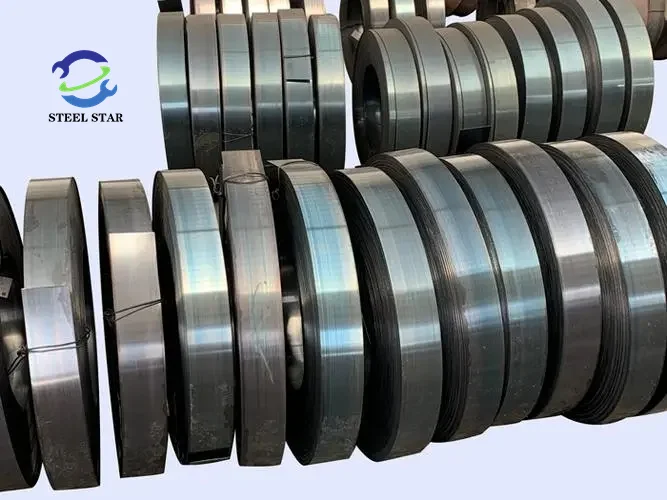

A metal coil slitting machine, often referred to as a slitter or coil slitter, is a fundamental industrial machine designed to cut wide master coils of metal into multiple narrower strips of precise widths. This process, known as slitting, is a critical first step in many metal fabrication supply chains, transforming bulk-purchased raw materials into customized sizes ready for further processing or end-use. From automotive components and construction materials to appliance manufacturing and electronics, slitting machines enable efficient material utilization and just-in-time production across countless industries.

Working Principle and Core Components

The slitting process involves unwinding a large metal coil, passing it through specialized rotary cutting tools, and rewinding the resulting narrower strips onto separate mandrels. A complete slitting line typically integrates these key stations:

- Pay-off/Uncoiler: A heavy-duty cradle or mandrel that holds and feeds the master coil (weighing up to 30+ tons) into the line. It may include a peeler head and tension control.

- Entry Guide & Flattener: Straightens and flattens the incoming strip to ensure consistent entry into the cutting section.

- Slitter Head: The machine’s core. It consists of:

- Arbors: Precision shafts onto which pairs of circular slitter knives are mounted.

- Top & Bottom Knives: Hardened tool steel or carbide rings. The top knives are positioned against the bottom knives to perform a scissor-like shear cut.

- Spacers: Precisely machined rings placed between the knives to determine the final strip width.

- Separator System (Stripper Ring/Shafts): Physically separates the slit strips after cutting to prevent interweaving and scratching.

- Tension Stand/Bridle: Maintains critical strip tension throughout the process.

- Re-coiler(s): One or more mandrels that rewind the individual slit strips into tight, Dual re-coilers allow for continuous operation.

- Scrap Winders: Collect the edge trim (skeleton) for recycling.

- Control System: A central PLC and HMI panel control line speed, tension, and automation sequences.

Types of Slitting Machines

Machines are categorized by their design, capability, and the end-product requirements:

- Loop (Pull-Through) Slitters: The simplest design. The strip forms a loop between the uncoiler and re-coiler, with tension provided solely by the re-coiler’s drag. Suitable for thinner, softer materials like aluminum foil or mild steel up to ~3mm.

- Single-Loop (Dual-Motor) Slitters: Feature synchronized drive motors on both the pull-through bridle and the re-coiler for better tension control in mid-range applications.

- Double-Loop (Precision/High-Tension) Slitters: The industry standard for high-quality slitting of thicker or high-strength materials. They use two tension stands to create independent, tightly controlled tension zones before and after the slitter head, ensuring exceptional strip shape, edge quality, and coil tightness.

- Multi-Head/Programmable Slitters: Feature multiple, quick-change slitter heads or CNC-adjustable knife positions for high-mix, low-volume production with minimal setup time.

Key Technical Specifications and Considerations

- Master Coil Capacity: Max width (e.g., 1500mm), thickness (e.g., 0.1-6.0mm), weight, and inside diameter (ID).

- Material Type: Capabilities for mild steel, high-strength steel (HSS), stainless steel, aluminum, copper, and pre-painted/metallic-coated coils.

- Slitter Head Design: Arbor diameter, max number of strips, knife overlap/clearance adjustment method (fixed, eccentric, or hydraulic).

- Tension Control: The sophistication of the system, often the key differentiator for final coil quality.

- Line Speed: Typically ranges from 30 m/min for heavy gauge to over 600 m/min for thin, soft materials.

- Accuracy: Strip width tolerance (can be as tight as ±0.1mm) and edge quality (burr-free).

Critical Role and Benefits in Manufacturing

- Cost Efficiency: Allows purchase of wider, lower-cost-per-ton master coils and customization to exact customer widths, minimizing waste.

- Supply Chain Flexibility: Enables service centers and fabricators to hold inventory in standard master coils and slit on-demand, reducing lead times.

- Quality Enhancement: Produces clean, precise edges critical for subsequent processes like stamping, roll forming, or tube making.

- Material Optimization: Advanced lines can perform multiple-width slitting to maximize yield from each master coil.

- Process Enabler: Essential for feeding other high-speed processes, such as roll forming or blanking lines, with specific strip dimensions.

Selection Criteria and Investment Factors

Choosing a slitting line involves balancing:

- Material Portfolio: The range of metals, gauges, and strengths to be processed.

- Production Volume & Mix: High-volume dedicated lines vs. flexible, quick-change systems.

- Quality Requirements: Edge condition, coil shape (tension level), and dimensional tolerances.

- Automation Level: From manual coil handling to fully automated lines with robotic pack-out.

- Tooling (Knives & Spacers): A significant ongoing cost; quality here dictates cut quality and longevity.

- Total Cost of Ownership: Includes initial investment, maintenance, tooling, energy use, and operational labor.

Technological Trends

- Automation & IoT: Robotic coil loading/unloading, automated knife setting, and predictive maintenance through sensor data.

- Digitalization: Line simulation software, production monitoring dashboards, and integration with ERP/MES systems.

- Advanced Controls: AI-driven tension and vibration control for optimal performance.

- Tooling Advancements: Coatings and new carbide grades for longer life and cleaner cuts in advanced materials.

The metal coil slitting machine is more than just a cutter; it is a sophisticated precision instrument that sits at the very beginning of the value chain for a vast array of manufactured goods. Its performance directly impacts material yield, downstream process efficiency, and final product quality. As industries demand stronger, thinner, and more specialized materials, slitting technology continues to evolve with greater precision, flexibility, and intelligence. For metal service centers and manufacturers, investing in the right slitting technology is a strategic decision that defines their capability, efficiency, and competitiveness in the marketplace.

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)