Metal Framing Machine: The Precision Engine of Modern Construction Framing

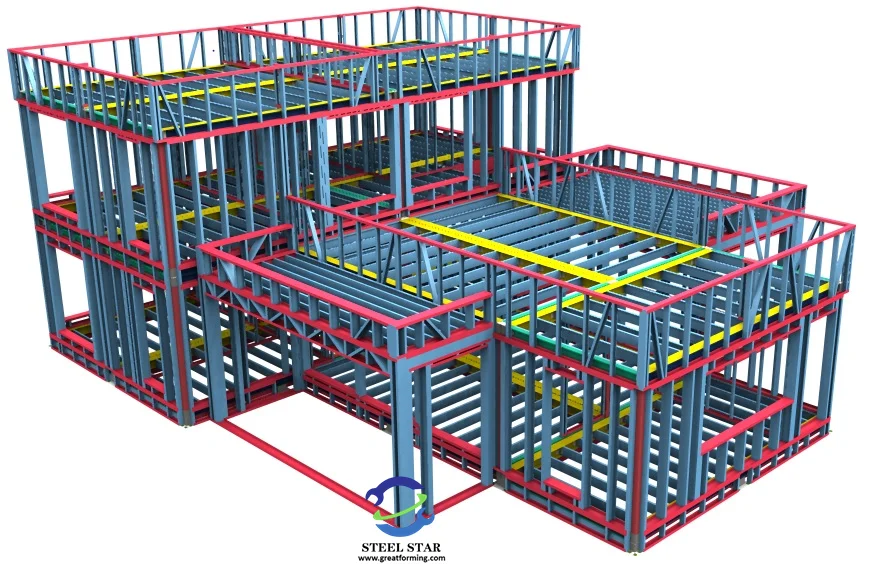

A Metal Framing Machine is a sophisticated manufacturing system designed for the high-volume production of structural and non-structural metal framing components, primarily light gauge steel (LGS) profiles. This equipment has revolutionized the construction industry by enabling efficient, precise, and automated fabrication of the steel skeletons used in modern commercial, residential, and industrial buildings, displacing traditional wood framing in many applications.

Core Function and Product Range

These machines specialize in cold roll forming metal coils into standardized profiles critical for construction:

- Studs & Tracks: C-shaped vertical studs and U-shaped horizontal tracks for wall assemblies.

- Runners & Channels: Furring channels, hat channels, and floor joists.

- Custom Profiles: Specialized shapes for trusses, lintels, and load-bearing applications.

By transforming galvanized steel coils (typically 0.5mm to 2.0mm thick) into these components, metal framing machines create structures that are fire-resistant, termite-proof, dimensionally stable, and recyclable.

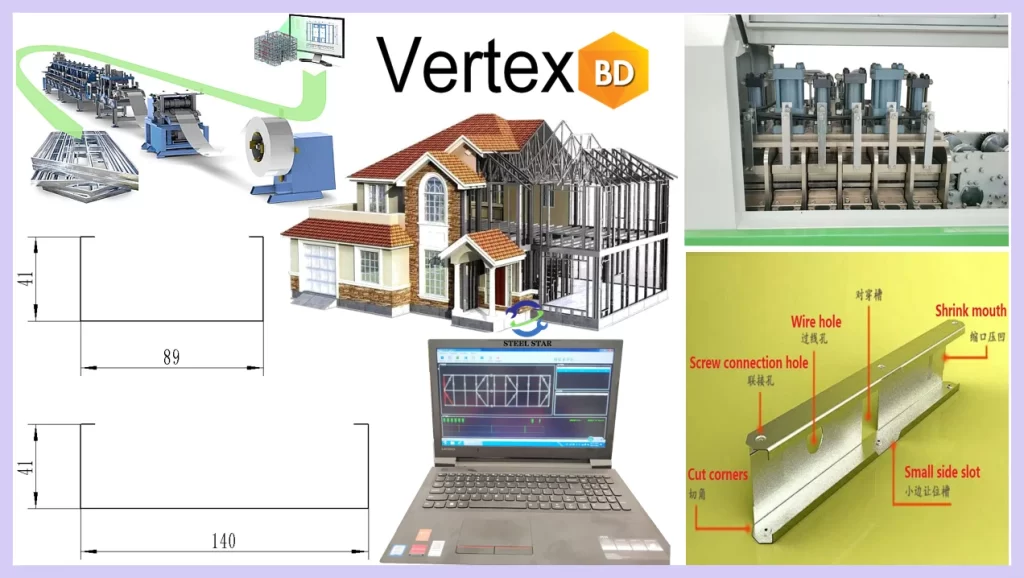

Integrated System Architecture

A complete metal framing production line integrates multiple processes into one continuous flow:

- Coil Handling System: Hydraulic decoiler with automatic loading arms feeds steel coil into the line, often integrated with a precision leveling unit to ensure flat material entry.

- Pre-Punching/Notching Station: The most critical subsystem for modern framing. Using servo-electric or hydraulic punching technology, this station automatically creates:

- Service Holes: Precisely spaced openings in studs for electrical wiring and plumbing.

- Pilot Holes: For screw fastening during assembly.

- End Notches: Complex cutouts at stud ends for secure track connections and web stiffeners.

- Roll Forming Section: The machine’s core, where 10-20+ stations of hardened steel roller dies progressively bend the flat, punched strip into the final C or U profile with exceptional dimensional consistency.

- Cut-off System: A high-speed servo or hydraulic flying cut shears the continuous profile to exact lengths (2400mm to 6000mm+ common) without stopping production, ensuring square, burr-free ends.

- Automated Output Handling: Finished studs/tracks are automatically counted, stacked, and bundled for strapping, ready for immediate shipment to construction sites.

Technological Advantages & Industry Impact

- Architectural Precision & Consistency: Produces components with tolerances within ±0.5mm, enabling rapid, predictable on-site assembly without the variability of wood framing. This precision is crucial for modern drywall and façade systems.

- Mass Production Efficiency: Capable of manufacturing hundreds of framing components per hour, dramatically outperforming manual fabrication while reducing labor costs by up to 70%.

- Material & Sustainability Optimization: Minimizes steel waste through precision pre-punching and cutting. The use of galvanized steel (with 40-70% recycled content) supports green building certifications like LEED.

- Design Flexibility Through Digital Integration: Modern machines accept BIM/CAD data directly, allowing instant production of custom profiles for complex architectural designs without retooling delays.

- Structural Performance Enhancement: The cold-forming process work-hardens steel at bend points, increasing yield strength by 15-20% at critical structural junctions.

Advanced Technological Features

- CNC Servo Punching Systems: Allow for rapid change between different hole patterns without mechanical adjustments, supporting mixed-batch production.

- IoT-Enabled Monitoring: Real-time tracking of production metrics, predictive maintenance alerts, and material consumption data through cloud-connected PLC systems.

- Laser Measurement Systems: In-line verification of profile dimensions and hole placement accuracy, with automatic correction feedback to the control system.

- Modular Tooling Design: Quick-change cartridge systems enable profile changeovers in under 15 minutes.

Market Applications & Evolution

Metal framing machines now serve expanding markets beyond commercial construction:

- Residential Construction: Growing adoption in single-family and multi-unit housing for hurricane and earthquake-resistant structures.

- Modular/Prefabricated Construction: Essential for manufacturing precision volumetric modules and panelized systems.

- Interior Fit-outs: Demountable partition systems for flexible office spaces.

- Specialized Structures: Data centers, clean rooms, and medical facilities requiring non-combustible, EMI-shielded, or hygienic wall systems.

Economic & Safety Implications

The technology has reshaped construction economics by:

- Reducing on-site construction time by 30-40% through prefabrication

- Lowering insurance costs due to non-combustible material properties

- Minimizing construction waste by over 90% compared to wood framing

- Enabling taller light-gauge steel structures through engineered connections

The Metal Framing Machine represents a paradigm shift in construction technology, bridging digital design with physical fabrication. As global construction trends increasingly favor precision, sustainability, and resilience, these automated systems have evolved from simple profile formers into intelligent manufacturing cells that fundamentally transform how buildings are conceived and constructed. By delivering engineered framing components with architectural precision at industrial scale, this technology continues to redefine the possibilities of modern construction while addressing critical challenges of labor shortages, material consistency, and building performance in the 21st century.

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)