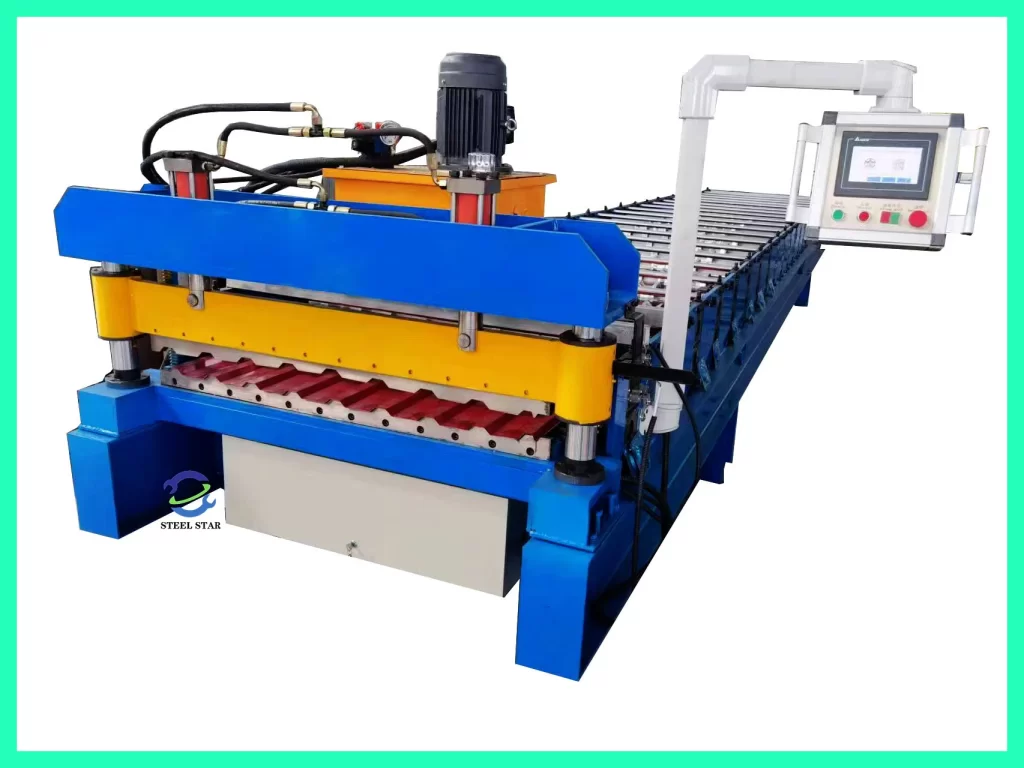

The Metal Roof Sheet Making Machine is a sophisticated, fully integrated production line that transforms raw metal coils into finished, high-performance roofing panels. As a cornerstone of modern construction material manufacturing, this machinery enables the efficient, precise, and cost-effective production of the durable metal sheets that define contemporary architectural landscapes for residential, commercial, and industrial buildings.

System Overview and Integrated Process

This equipment represents a complete manufacturing cell that performs multiple operations in one continuous, automated sequence. The process begins with a master coil of pre-painted galvanized steel, Galvalume, or aluminum and concludes with stacked, cut-to-length panels ready for installation. Unlike standalone roll formers, these integrated lines incorporate all necessary pre- and post-forming processes.

Key Components and Workflow

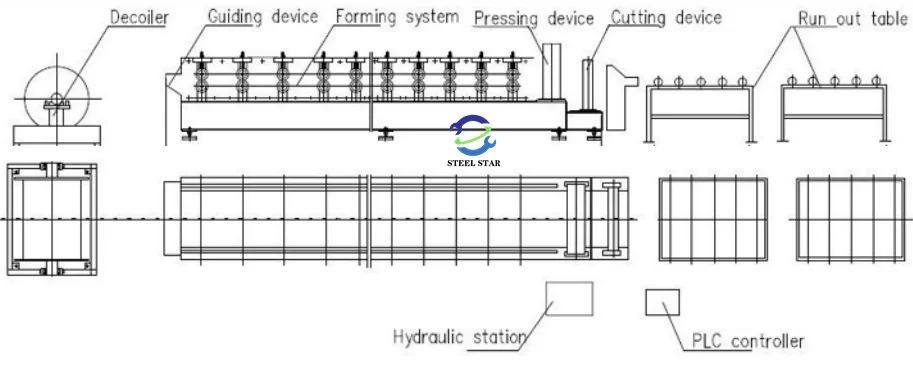

- Coil Handling & Feeding: A hydraulic decoiler with automatic loading arms positions and feeds the coil (typically 1-6 tons) into the line. An entry pinch roll assembly ensures consistent material advancement.

- Pre-Forming Processing Station: This critical stage often includes:

- Pre-Punching/Notching: A servo-controlled punching unit creates precise trim profiles, fastener holes, or ventilation patterns in the flat metal strip before forming, allowing for complex panel designs and side-lap configurations.

- Embossing: Optional rolls can imprint wood-grain or other aesthetic textures onto the metal surface for enhanced architectural appeal.

- The Roll Forming Core: The flat, processed strip enters the forming section. Here, a series of 10-20+ paired roller dies, mounted on a heavy-duty frame, progressively and gradually bend the metal into the desired roof profile (e.g., standing seam, trapezoidal/ribbed, tile profile). This cold-forming process preserves the metal’s protective coatings and increases strength through work-hardening at the bends.

- Precision Cut-to-Length: A flying cut-off system—hydraulic for robustness or servo-driven for superior speed and accuracy—shears the continuously moving formed panel to exact project lengths without stopping the production line.

- Automated Output Handling: Finished sheets are conveyed to an automatic stacker, which counts and neatly piles them for strapping and shipment, minimizing manual handling and risk of damage.

Operational Advantages and Impact

- Turnkey Production Efficiency: Delivers ready-to-install sheets directly from raw material, streamlining the entire supply chain from manufacturer to job site.

- Exceptional Quality and Consistency: Produces panels with uniform geometry, appearance, and mechanical properties batch after batch, which is critical for waterproof performance, structural integrity, and aesthetic harmony on the roof.

- High-Speed, Low-Waste Manufacturing: Operates at line speeds of 15-50+ meters per minute, dramatically increasing output while minimizing material scrap through precise control and pre-cut optimization.

- Unmatched Profile Versatility: With quick die changes, a single machine can produce a vast range of profiles, widths, and lengths, allowing manufacturers to meet diverse architectural specifications and market demands with one flexible asset.

- Labor and Cost Optimization: High automation reduces direct labor requirements and associated human error, while integrated processing lowers per-unit production costs.

Advanced Technological Features

Modern machines are defined by intelligent integration:

- Centralized PLC Control: A programmable logic controller with a user-friendly HMI (Human-Machine Interface) manages all functions—speed, length, quantity, punching patterns—and stores hundreds of production recipes for instant recall.

- Servo-Driven Precision: Servo motors for punching and cutting provide unparalleled accuracy, flexibility for complex patterns, quieter operation, and energy savings.

- In-Line Quality Assurance: Options include laser measurement systems to monitor panel dimensions and profile geometry in real-time, ensuring consistent quality.

- Robust Construction: Fabricated from high-grade steel with precision-machined, hardened alloy roller dies to ensure longevity and stability under constant high-volume operation.

Industry Significance and Applications

The panels produced are essential for:

- Commercial & Industrial Buildings: Warehouses, factories, logistics centers, and big-box retail stores.

- Agricultural Structures: Barns, storage facilities, and processing plants.

- Institutional & Public Projects: Schools, stadiums, and airports.

- Residential Roofing: Growing in popularity for its longevity and modern aesthetics.

This technology directly supports the global shift toward durable, sustainable, and recyclable building materials that offer superior life-cycle performance compared to traditional asphalt shingles or concrete tiles.

The Metal Roof Sheet Making Machine is more than mere fabrication equipment; it is a precision-engineered system that encapsulates the principles of Industry 4.0 in metal construction. By seamlessly integrating material handling, value-added processing, precision forming, and automated logistics, it empowers manufacturers to supply the construction industry with high-quality, reliable, and innovative roofing solutions. As architectural trends and performance demands evolve, this machinery continues to advance, forming the essential link between raw material innovation and the durable, weather-tight roofs that shelter global infrastructure.

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)