Metal Roofing: A Durable, Sustainable, and Versatile Option

Introduction

In the world of roofing, metal roofing has emerged as a popular and reliable choice for both residential and commercial buildings. With its unique set of properties, metal roofing offers numerous advantages over traditional roofing materials such as asphalt shingles, clay tiles, or wood shakes. This article delves deep into the various aspects of metal roofing, including its history, materials used, manufacturing processes, installation techniques, benefits, drawbacks, maintenance requirements, and future trends.

History of Metal Roofing

The use of metal for roofing dates back centuries. Early civilizations, such as the Greeks and Romans, were known to use lead sheets for roofing due to its malleability and corrosion resistance. In medieval Europe, copper was favored for prestigious buildings like churches and castles because of its durability and aesthetic appeal as it developed a beautiful patina over time.

However, it was during the Industrial Revolution in the 19th century that metal roofing truly began to take off. The mass production of steel and the development of new manufacturing techniques made metal roofing more affordable and accessible. Tin-coated steel sheets, known as tin roofs, became widespread in the United States, especially in rural areas and for industrial buildings. As technology advanced, other metals like aluminum and zinc were introduced, each bringing their own unique characteristics to the roofing market.

Materials Used in Metal Roofing

Steel

Steel is one of the most commonly used metals for roofing. It is known for its strength and durability, capable of withstanding heavy winds, hail, and snow loads. Galvanized steel, which has a zinc coating, is highly resistant to corrosion. This makes it suitable for a wide range of climates, from humid coastal regions to areas with harsh winters. Additionally, steel can be painted in various colors, allowing for customization to match the architectural style of any building.

Aluminum

Aluminum is lightweight, making it an excellent choice for buildings where structural support may be a concern. It is also highly resistant to rust and corrosion, even in saltwater environments, which makes it popular in coastal areas. Aluminum roofing reflects sunlight well, contributing to energy efficiency by reducing heat absorption and, consequently, cooling costs in warmer months.

Copper

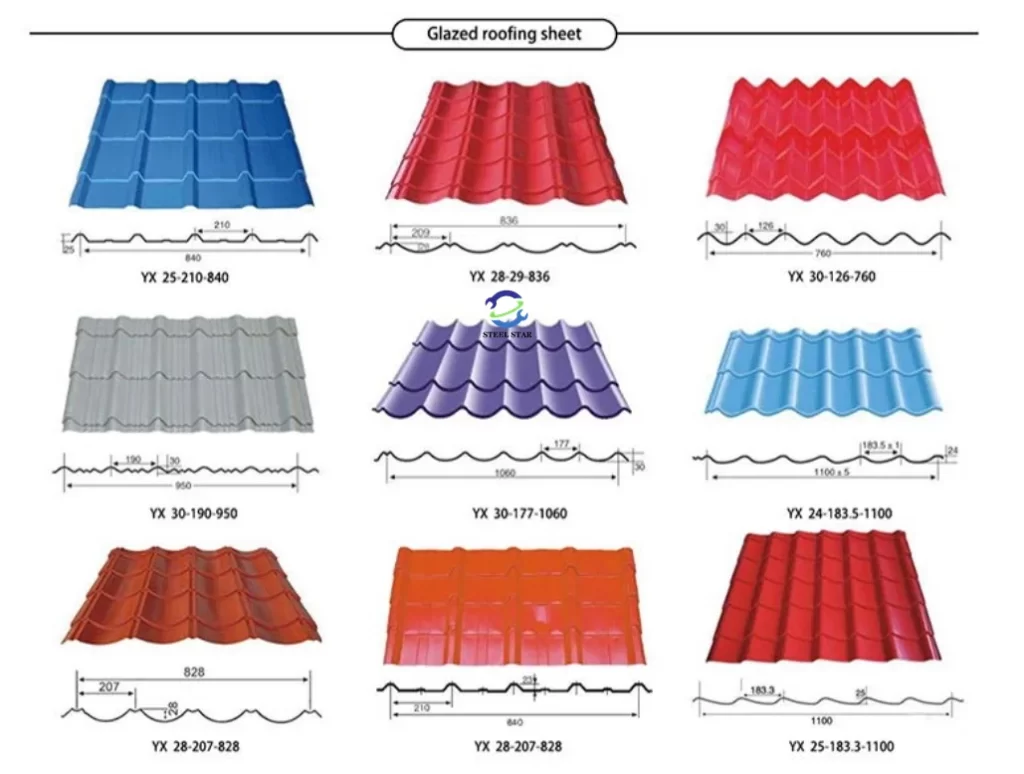

Copper is a premium metal roofing material renowned for its elegance and longevity. Over time, copper develops a natural green patina that not only protects the metal from further corrosion but also gives buildings a distinct and timeless look. It is extremely durable, with some copper roofs lasting over a century. Copper is often used in high-end residential and historic preservation projects.

Zinc

Zinc roofing has gained popularity in recent years. It is self-healing in the sense that minor scratches or abrasions on the surface will oxidize and reseal themselves, preventing corrosion from spreading. Zinc is also recyclable, adding to its environmental credentials. It has a sleek, modern appearance and is suitable for contemporary architectural designs.

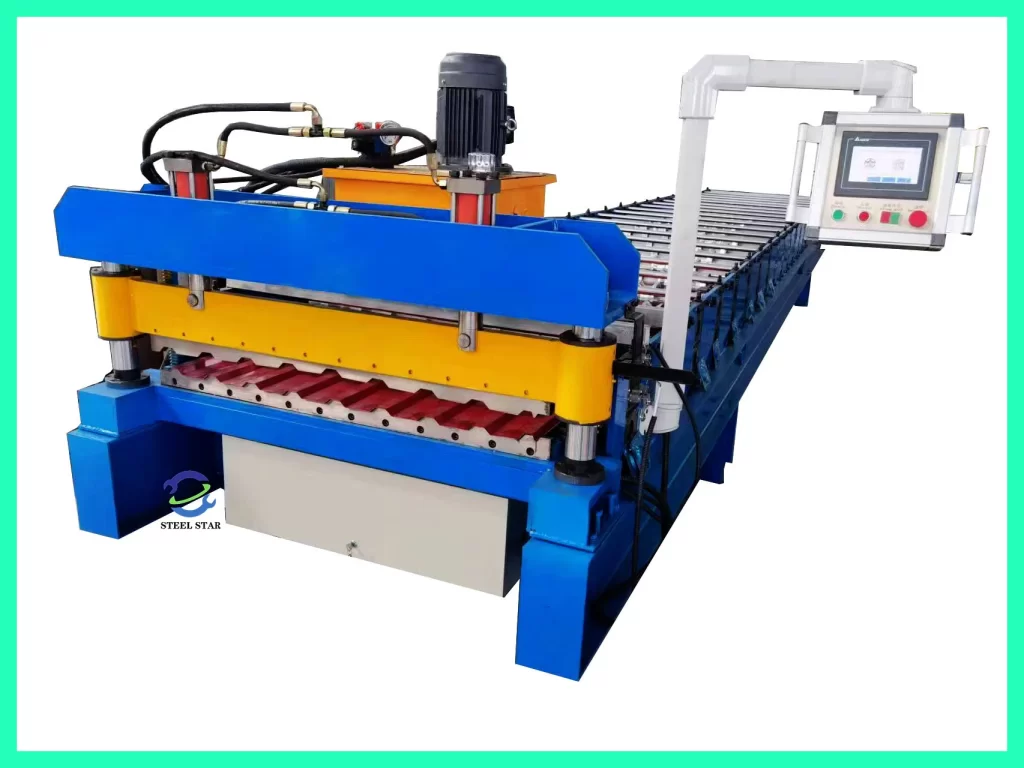

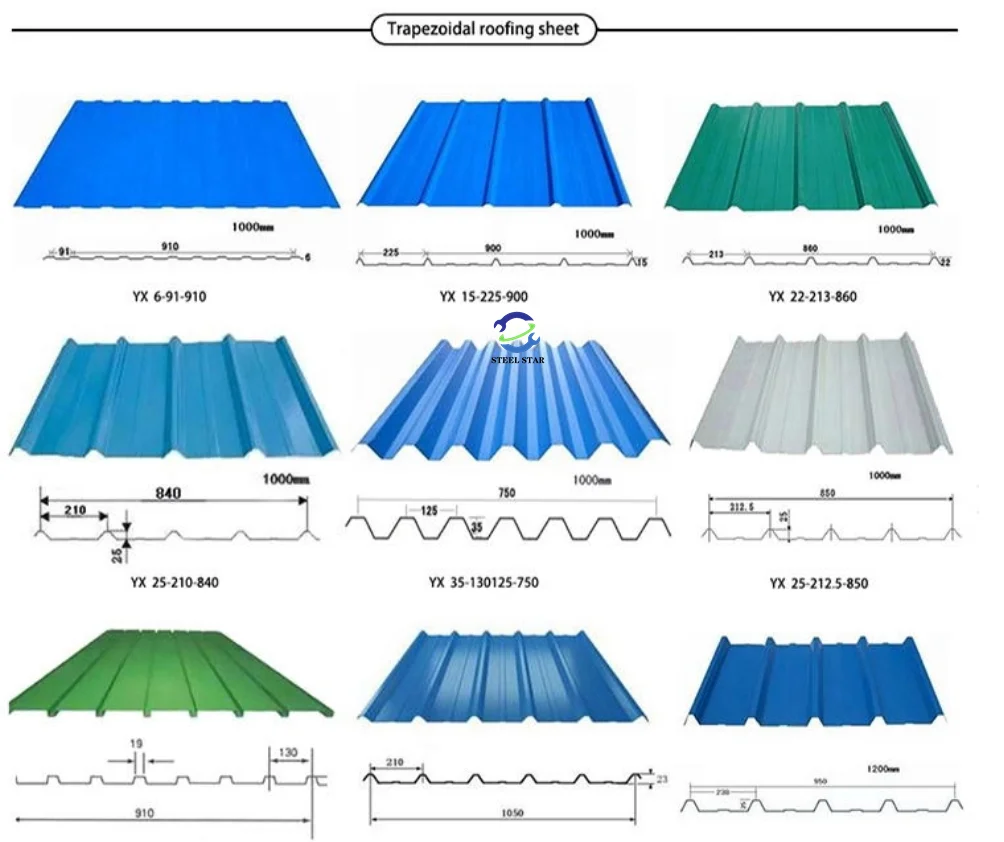

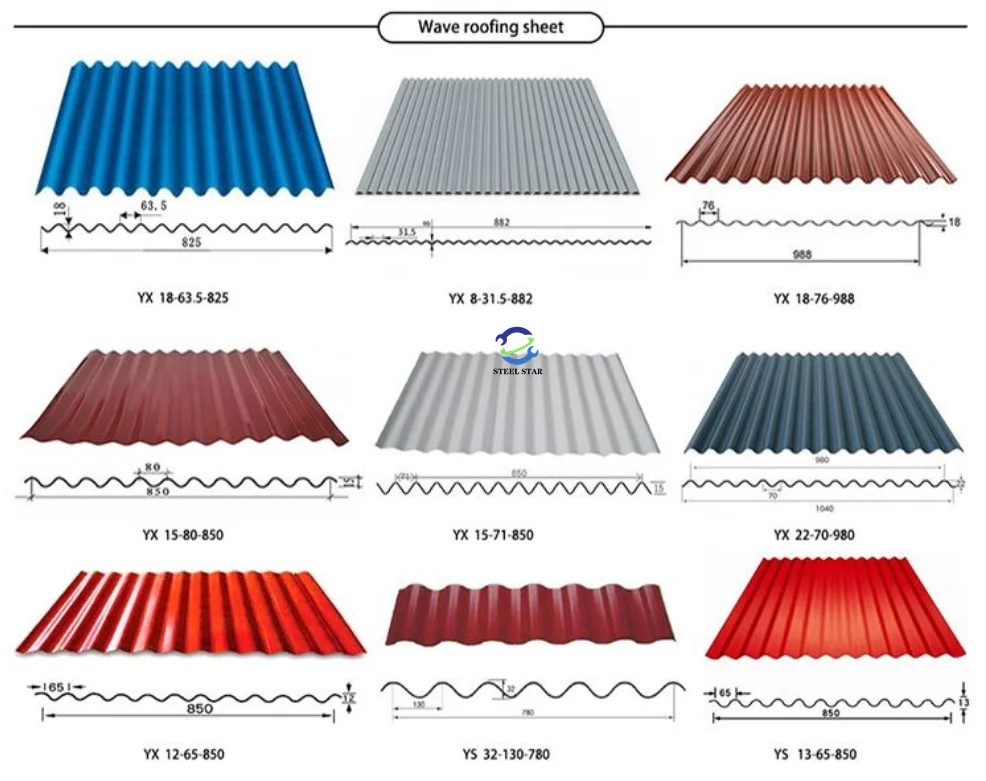

Manufacturing Processes

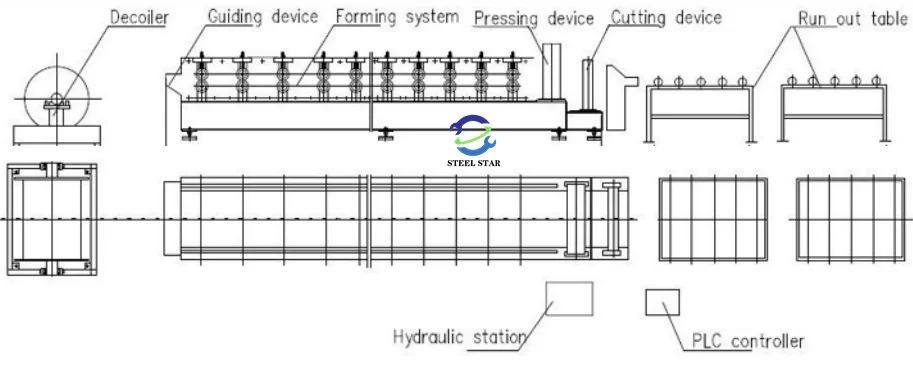

Metal roofing panels are manufactured through several processes. Roll forming is a common method where coils of metal are fed through a series of rollers that gradually shape the metal into the desired profile, whether it’s standing seam, corrugated, or other designs. This process allows for high precision and mass production.

Coating is another crucial step. For steel, galvanizing is typically done by immersing the metal in a bath of molten zinc. Some manufacturers also apply additional paint coatings for enhanced durability and aesthetics. These coatings can be polyester, acrylic, or fluoropolymer-based, with fluoropolymer coatings offering the highest level of resistance to fading, chalking, and weathering.

For aluminum and zinc, the metals may be alloyed with other elements to improve their properties. For example, aluminum is sometimes alloyed with magnesium or manganese to increase its strength. The manufacturing process also involves quality control checks to ensure the panels meet strict standards for thickness, coating integrity, and dimensional accuracy.

Installation Techniques

Proper installation is key to the performance and longevity of a metal roof. Standing seam roofs, for instance, are installed using concealed fasteners. Panels with interlocking seams are snapped together, and the fasteners are hidden within the raised seams. This not only gives a clean, sleek appearance but also reduces the risk of leaks as there are no exposed screws on the roof surface.

Corrugated metal roofs are often screwed directly onto the roof deck, with care taken to ensure proper spacing of the fasteners to prevent buckling or warping of the panels. In both cases, underlayment is typically installed first. This can be a synthetic or felt underlayment that provides an extra layer of protection against water infiltration, especially in areas prone to heavy rain or snow.

Installation also requires attention to flashing details around chimneys, skylights, and roof edges. Properly installed flashing, made of the same or compatible metal as the roofing panels, directs water away from vulnerable areas and prevents leaks. Professional installers follow manufacturer guidelines closely and may use specialized tools like seamers and crimpers to ensure a tight and secure fit of the metal panels.

Benefits of Metal Roofing

Durability

Metal roofs have an impressively long lifespan. Depending on the metal used and the quality of installation, they can last anywhere from 30 to 70 years or more. They are highly resistant to damage from wind, hail, and fire. In areas prone to wildfires, metal roofing can provide a crucial line of defense, as it is non-combustible. Additionally, metal roofs do not rot, split, or crack like some organic roofing materials, maintaining their integrity over time.

Energy Efficiency

As mentioned earlier, metals like aluminum and some coated steel panels have high reflectivity. They reflect a significant portion of the sun’s radiant heat, reducing the amount of heat transferred into the building. This can lead to lower cooling costs in summer. In winter, metal roofing can also help retain heat when combined with proper insulation, as it acts as a barrier against cold air infiltration. Some metal roofs are even eligible for energy efficiency rebates and incentives due to their positive impact on a building’s energy consumption.

Low Maintenance

Metal roofs require minimal maintenance compared to other roofing options. There is no need for regular treatments like sealing or staining as with wood roofs. Occasional inspections to check for loose fasteners, damage from fallen branches or debris, and proper drainage are usually sufficient. If there is any surface dirt or staining, it can often be cleaned with mild detergent and water. The coatings on metal roofs are designed to be long-lasting, and if they do fade or wear over time, recoating is a relatively straightforward process.

Aesthetic Appeal

Metal roofing offers a wide range of design possibilities. From the classic look of standing seam copper roofs on historic homes to the sleek, modern appearance of zinc or painted aluminum panels on contemporary buildings, there is a metal roofing style to suit every architectural taste. The ability to choose from various colors, profiles, and finishes allows homeowners and architects to create unique and visually striking roofs.

Sustainability

Metal roofing is an environmentally friendly choice. Most metals used in roofing are recyclable at the end of their life cycle, reducing landfill waste. The long lifespan of metal roofs also means fewer replacements over time, conserving resources and energy associated with manufacturing new roofing materials. Additionally, the energy-efficient properties of metal roofing contribute to reducing a building’s carbon footprint.

Drawbacks of Metal Roofing

Initial Cost

One of the main deterrents for some property owners is the initial cost of metal roofing. It is generally more expensive than asphalt shingles upfront. The cost of materials, especially premium metals like copper, and the specialized installation required can significantly increase the overall project cost. However, it’s important to consider the long-term value and savings in maintenance and energy costs over the life of the roof.

Noise

Some people are concerned about the noise level during rain or hail storms on a metal roof. While it’s true that metal can be noisy, modern installation techniques and the use of proper insulation and underlayment can mitigate this issue. Insulation helps absorb sound, and the design of many metal roofing profiles, such as standing seam, reduces the drumming effect that can occur with flat metal sheets.

Expansion and Contraction

Metals expand and contract with temperature changes. If not properly installed with adequate allowance for movement, this can lead to buckling, warping, or loosening of panels. Professional installers are trained to account for thermal expansion by leaving appropriate gaps and using fastening systems that can accommodate movement without compromising the roof’s integrity.

Maintenance Requirements

Regular inspections are the cornerstone of metal roof maintenance. At least twice a year, homeowners or building managers should visually inspect the roof for any signs of damage, such as dents from hail, loose or missing fasteners, or clogged gutters and downspouts. If there are trees near the building, it’s important to check for branches that could scratch or damage the roof surface.

Cleaning can be done as needed, typically using a soft brush or low-pressure water spray to remove dirt, leaves, and debris. Avoid using abrasive cleaners or high-pressure washing, as these can damage the roof’s coating. If there are any areas of rust on a steel roof, they should be promptly treated with a rust converter and repainted to prevent further corrosion.

Checking the flashing around roof penetrations and edges is crucial. If the flashing shows signs of wear, cracking, or separation, it should be repaired or replaced immediately to maintain the roof’s watertight seal. Additionally, after severe weather events like strong winds or heavy snow, a thorough inspection is recommended to identify any potential issues that may have arisen.

Future Trends in Metal Roofing

The future of metal roofing looks promising, with several emerging trends. One significant development is the integration of solar panels with metal roofing systems. Thin-film solar cells can be laminated directly onto metal roofing panels, creating a seamless and efficient energy-generating solution. This not only maximizes a building’s use of roof space but also simplifies installation compared to traditional separate solar panel setups.

Advances in coating technologies are also on the horizon. Nanocoatings are being developed that offer even greater durability, self-cleaning properties, and enhanced resistance to environmental pollutants. These coatings could further extend the lifespan of metal roofs and reduce maintenance needs.

In terms of design, there is a growing trend towards more complex and customized metal roofing profiles. Architects are increasingly specifying unique shapes and textures to create signature looks for buildings, and manufacturers are responding with innovative forming techniques to meet these demands. Additionally, as sustainability becomes a more critical factor in building design, the recyclability and energy-efficient features of metal roofing will continue to be emphasized and improved upon.

Conclusion

Metal roofing has come a long way from its early beginnings and has firmly established itself as a top choice for many building projects. Its combination of durability, energy efficiency, low maintenance, aesthetic versatility, and sustainability makes it a compelling option. While there are some initial cost and installation considerations, the long-term benefits far outweigh the drawbacks. As technology continues to evolve and new trends emerge, metal roofing is poised to play an even more significant role in the roofing industry, providing reliable and innovative solutions for buildings of the future. Whether it’s a quaint cottage, a modern office building, or a historical landmark, metal roofing offers a roofing solution that combines form and function in an exemplary manner.

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)