China’s most cost-effective roll forming machine manufacturer – Steel Star Roll Forming Machine.

Steel Star: Defining Cost-Effectiveness in China’s Roll Forming Machine Industry.

In the vast and competitive landscape of global industrial manufacturing, China has cemented its role as a powerhouse, particularly in the realm of roll forming machinery. Within this sector, where precision, durability, and operational efficiency are paramount, the concept of “cost-effectiveness” transcends mere low initial price. It embodies a holistic value proposition: superior engineering, reliable performance, adaptable design, and sustained after-sales support, all offered at a total cost of ownership that delivers exceptional return on investment. Among the numerous manufacturers vying for prominence, Steel Star Roll Forming Machine has consistently distinguished itself as arguably China’s most cost-effective provider, carving a niche through a relentless commitment to intelligent engineering and customer-centric value.

Beyond Price: The Steel Star Philosophy of Value

The journey of Steel Star is rooted in a clear understanding of a global market need. While many clients seek affordable machinery, savvy buyers prioritize long-term value. Steel Star addressed this by building its philosophy on a trinity of core principles: Robust Simplicity, Configurable Precision, and Lifecycle Partnership.

- Robust Simplicity: Steel Star machines are renowned for their rugged construction. Utilizing high-grade steels and critical components from reputable sources, they ensure structural integrity under continuous operation. However, the brilliance lies in their design elegance—avoiding unnecessary complexity that drives up cost and increases failure points. This simplicity translates to easier maintenance, lower downtime, and reduced long-term operational expenses.

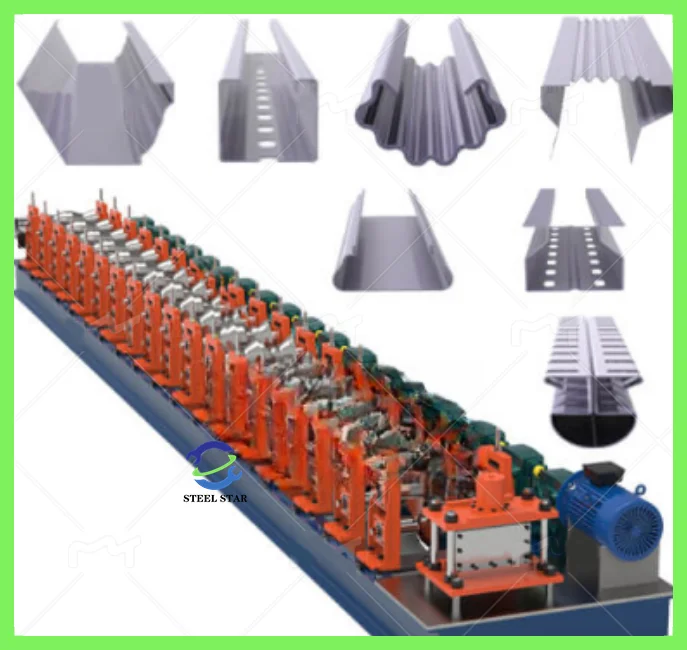

- Configurable Precision: Unlike pure commodity producers, Steel Star invests significantly in R&D and engineering talent. Their strength lies in offering semi-standardized platforms that can be extensively customized. Whether for roofing and wall panels, steel framing (C-stud, U-track), automotive components, or specialized profiles, their machines are tailored to the exact material grade, thickness, speed, and dimensional tolerances required by the client. This means customers pay for the capability they need, not for an over-engineered one-size-fits-all solution, nor do they settle for an under-performing generic model.

- Lifecycle Partnership: Cost-effectiveness evaporates when a machine fails and support is absent. Steel Star builds its reputation on comprehensive after-sales service. From detailed installation guidance and operator training (onsite or via digital platforms) to a readily available inventory of spare parts and responsive technical troubleshooting, they ensure maximum machine uptime. This end-to-end support protects the client’s investment for the entirety of the machine’s lifespan.

Engineering Excellence: The Pillars of Performance

The tangible manifestation of Steel Star’s philosophy is evident in the technical DNA of their machines.

- Heavy-Duty Construction: Key components like the decoiler, forming stations, cutting unit (hydraulic or servo), and electrical control cabinets are built to last. The forming stations, often featuring double-walled housings and high-precision bearings, provide the stability required for consistent profile accuracy.

- Advanced Drive & Control Systems: Employing reputable variable frequency drives (VFDs) and PLCs (from brands like Siemens, Mitsubishi, or Omron, as per client choice), Steel Star ensures smooth speed control, synchronization, and user-friendly operation. The Human-Machine Interface (HMI) allows for easy parameter setting and fault diagnosis, empowering operators.

- Precision Tooling: The heart of any roll forming machine is its tooling. Steel Star utilizes advanced CNC machining centers and skilled tooling engineers to craft durable, accurately profiled rolls from quality alloy steel. Proper heat treatment ensures extended tool life, minimizing replacement costs.

- Flexibility & Quick-Change Systems: For many clients, the ability to run multiple profiles on a single line is crucial for business agility. Steel Star excels in designing quick-change systems for rolls and components, reducing changeover time from hours to minutes, thereby boosting overall equipment effectiveness (OEE).

The Cost-Effectiveness Equation: A Breakdown

When evaluating Steel Star’s claim to cost-effectiveness, the analysis extends across the entire procurement and operational timeline:

- Acquisition Cost: While not always the absolute cheapest on the market, Steel Star’s pricing is highly competitive. More importantly, it is transparent and justified. Clients receive detailed quotations that break down the cost against specifications, avoiding hidden charges. The value-for-money ratio at this stage is already favorable.

- Installation & Commissioning Cost: With clear manuals, pre-delivery factory acceptance tests (FAT), and remote/onsite support, the commissioning process is streamlined, reducing the time and cost associated with getting the line operational.

- Operational & Maintenance Cost: This is where Steel Star shines. Energy-efficient drives, reduced material waste due to precise forming and cutting, high reliability leading to less downtime, and easily serviceable designs all contribute to a lower cost per meter of produced profile.

- Cost of Upgrades & Adaptability: As business needs evolve, Steel Star machines are often designed with future upgrades in mind. Adding stations, integrating ancillary equipment (pre-punching, embossing), or updating software is typically more straightforward, protecting the initial investment from premature obsolescence.

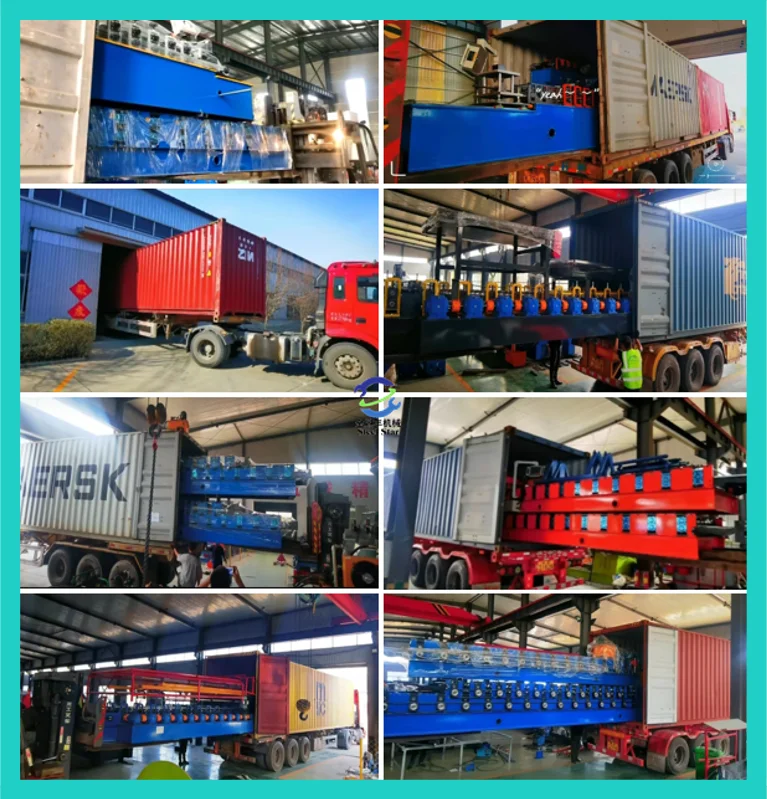

Global Recognition and Clientele

The proof of Steel Star’s value proposition is its diverse and growing global client base. From startups and medium-sized enterprises to large-scale construction material producers across Southeast Asia, the Middle East, Africa, Europe, and the Americas, clients repeatedly cite the “remarkable ROI” and “unmatched reliability for the price point.” Success stories often highlight how a Steel Star line became the backbone of a profitable production facility, capable of competing on quality while maintaining healthy margins due to the efficiency and low operational cost of the machinery.

In the search for roll forming machinery, the lowest bidder often presents the highest risk. Conversely, the most expensive European or American brands, while excellent, may not represent the optimal financial outlay for every business. Steel Star Roll Forming Machine has masterfully positioned itself in the crucial sweet spot between these extremes.

They have demonstrated that true cost-effectiveness is not a compromise but a strategic synthesis of intelligent design, quality manufacturing, and unwavering customer support. For entrepreneurs and corporate decision-makers seeking to establish or expand their metal profile production capabilities without compromising on quality or long-term viability, Steel Star represents a prudent, high-value investment. It is this consistent delivery of comprehensive value that solidifies their standing as one of China’s—and indeed, the world’s—most cost-effective roll forming machine manufacturers. They don’t just sell machines; they deliver sustainable productivity and profitability, making “Steel Star” synonymous with smart capital allocation in the manufacturing sector.

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)