Technical Parameters :

- Thickness of sheet : 0.15mm — 3.0mm (Can be customized according to your needs)

- Voltage : 380v 50hz 3phase / 220v 60hz 3phase (Can be customized according to your needs)

- Language : English / Spanish / Arabic / Russian / Portuguese / German / French (Can be customized according to your needs)

- Motor brand : Siemens / other (Can be customized according to your needs)

- Meters:1M / 2M / 4M / 6M / 8M / 10M / 12M (Can be customized according to your needs)

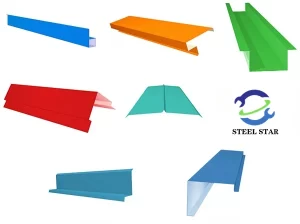

Application Scenarios :

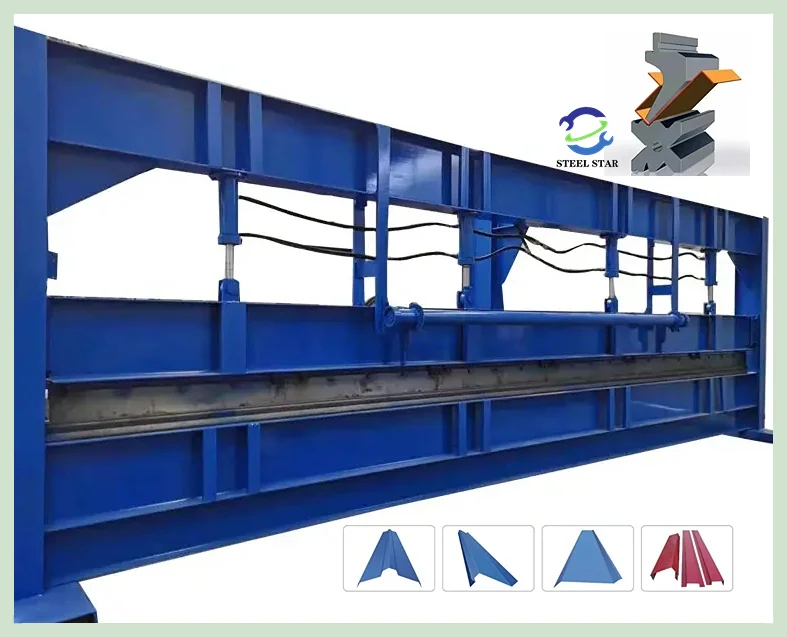

Structural features :

1. All-steel welded structure with sufficient strength and rigidity;

2. Hydraulic transmission, the oil cylinders at both ends of the machine tool are placed on the slide to directly drive the sliding work;

3. The slide synchronization mechanism adopts torsion shaft forced synchronization;

4. Mechanical block structure is adopted, which is stable and reliable;

5. The slide stroke can be adjusted quickly and manually, and the counter can be displayed;

6. The wedge-shaped deflection compensation mechanism can ensure a higher bending accuracy.

Working principle :

The hydraulic bending machine includes a bracket, a workbench and a clamping plate. The workbench is placed on the bracket. The workbench consists of a base and a clamping plate. The base is connected to the clamping plate through a hinge. The base consists of a base shell, a coil and a cover plate. The coil is placed in the depression of the base shell, and the top of the depression is covered with a cover plate.

When in use, the coil is energized by a wire, and after energization, an attractive force is generated on the clamping plate, thereby clamping the thin plate between the clamping plate and the base. Due to the use of electromagnetic force clamping, the clamping plate can be made into a variety of workpiece requirements, and workpieces with side walls can be processed. The bending machine can meet the needs of various workpieces by replacing the bending machine mold.

Main categories : Bending machines are divided into manual bending machines, hydraulic bending machines and CNC bending machines. Manual bending machines are further divided into mechanical manual bending machines and electric manual bending machines. Hydraulic bending machines can be divided into torsion axis synchronization, mechanical-hydraulic synchronization, and electro-hydraulic synchronization according to the synchronization mode. Hydraulic bending machines can be divided into upper-moving type and lower-moving type according to the movement mode.

The bending machine is an important equipment for bending and forming workpieces in the sheet metal industry. Its function is to press steel plates into parts of various shapes according to process requirements. As shown in the “Schematic Diagram of the Structure of Hydraulic Sheet Metal Bending Machine”, the frame is mainly composed of left and right columns, a workbench, and a crossbeam. The left and right cylinders are fixed on the columns. The slider is connected to the piston of the cylinder and moves up and down along the guide rail fixed on the column. The lower die is fixed on the workbench, and the upper die is installed at the lower end of the slider. The hydraulic system provides power and the electrical system gives instructions. Under the action of the cylinder, the slider drives the upper die downward and closes with the lower die to achieve the bending of the sheet metal. The left and right columns, the workbench and the slider (hereinafter referred to as the three major parts) are the key parts of the bending machine. The sum of the weight of the three major parts accounts for 70%~80% of the total weight of a bending machine. Its strength and rigidity directly determine the operating accuracy, service life, and accuracy of the workpiece of the machine tool.

Maintenance and care :

Before performing machine maintenance or cleaning, the upper die should be aligned with the lower die and then lowered and shut down until the work is completed. If you need to start the machine or perform other operations, you should select the manual mode and ensure safety. The maintenance contents are as follows:

1. Hydraulic oil circuit

1) Check the oil level in the oil tank every week. If the hydraulic system is repaired, it should also be checked. If the oil level is lower than the oil window, hydraulic oil should be added;

2) The hydraulic oil used in this machine is ISO HM46 or MOBIL DTE25;

3) The oil should be changed after the new machine has worked for 2000 hours, and the oil should be changed every 4000-6000 hours thereafter. The oil tank should be cleaned every time the oil is changed;

4) The system oil temperature should be between 35℃ and 60℃, and should not exceed 70℃. If it is too high, it will cause the oil quality and accessories to deteriorate and be damaged.

2. Filters

1) Every time you change the oil, the filter should be replaced or cleaned thoroughly;

2) If the machine tool has related alarms or other filters such as unclean oil quality, they should be replaced;

3) The air filter on the oil tank should be checked and cleaned every 3 months, and it is best to replace it once a year.

3. Hydraulic components

1) Clean the hydraulic components (base plate, valve, motor, pump, oil pipe, etc.) every month to prevent dirt from entering the system. Do not use detergents;

2) After a new machine has been used for one month, check whether the bends of the oil pipes are deformed. If there are any abnormalities, they should be replaced. After two months of use, the connections of all accessories should be tightened. When doing this work, the machine should be turned off and the system should be pressure-free.

If you make the wrong choice when purchasing a press brake, production costs will rise and the press brake cannot be expected to pay for itself. Therefore, there are several factors that must be weighed in the decision.

Workpiece

The first important thing to consider is the part you want to produce. The key point is to buy a machine that can complete the processing task with the shortest table and the smallest tonnage.

Carefully consider the material grade and the maximum processing thickness and length. If most of the work is mild steel with a thickness of 16 gauge and a maximum length of 10 feet (3.048 meters), the free bending force does not need to be greater than 50 tons. However, if you do a lot of bottom die forming, you may want to consider a 160-ton machine.

Assuming the thickest material is 1/4 inch, 10 feet of free bending requires 200 tons, while bottom die bending (corrective bending) requires at least 600 tons. If most of the work is 5 feet or shorter, the tonnage is almost halved, which greatly reduces the acquisition cost. Part length is very important in determining the specifications of the new machine.

Deflection

The 10-foot machine table and slide will deflect four times as much as the 5-foot machine under the same load. This means that the shorter machine requires fewer shim adjustments to produce acceptable parts. Fewer shim adjustments also reduce setup time.

Material grade is also a key factor. Stainless steel typically requires about 50% more load than mild steel, while most grades of soft aluminum require about 50% less. You can always get a tonnage chart from the press brake manufacturer that shows an estimate of the tonnage required per foot of length for different thicknesses and different materials.

Bend Radius

When free bending, the bend radius is 0.156 times the die opening distance. In the free bending process, the die opening distance should be 8 times the thickness of the metal material. For example, when forming 16 gauge mild steel with a 1/2 inch (0.0127 meter) opening distance, the part has a bend radius of about 0.078 inches. If the bend radius is almost as small as the material thickness, a bottom die forming is required. However, the pressure required for bottom die forming is about 4 times greater than free bending.

If the bending radius is less than the material thickness, a punch with a front corner radius less than the material thickness must be used, and the impression bending method must be used. In this way, 10 times the pressure of free bending is required.

For free bending, the punch and die are processed at 85° or less (smaller is better). When using this set of dies, pay attention to the gap between the punch and die at the bottom of the stroke, and the excessive bending that is sufficient to compensate for the rebound and keep the material at about 90°.

Usually, the springback angle produced by the free bending die on a new bending machine is ≤2°, and the bending radius is equal to 0.156 times the die opening distance. For bending with a bottom die, the die angle is generally 86 ~ 90°. At the bottom of the stroke, there should be a gap between the punch and die that is slightly larger than the material thickness. The forming angle is improved because the tonnage of the bottom die bending is larger (about 4 times that of free bending), which reduces the stress that usually causes springback within the bending radius.

Stamping bending is the same as bottom die bending, except that the front end of the punch is machined to the required bending radius, and the gap between the punch and the die at the bottom of the stroke is less than the material thickness. Since sufficient pressure (about 10 times that of free bending) is applied to force the front end of the punch to contact the material, springback is basically avoided.

In order to select the lowest tonnage specification, it is best to plan for a bending radius greater than the material thickness and use free bending as much as possible. When the bending radius is large, it often does not affect the quality of the part and its future use.

Curvature

Bending accuracy requirements are a factor that needs to be carefully considered. It is this factor that determines whether a CNC bending machine or a manual bending machine is needed. If the bending accuracy requires ±1° and cannot be changed, you must focus on the CNC machine.

The repeatability of the slider of the CNC bending machine is ±0.0004 inches, and the precise angle of forming must be formed with such accuracy and good molds. The repeatability of the slider of the manual bending machine is ±0.002 inches, and generally a deviation of ±2~3° will occur under the condition of using the appropriate mold. In addition, CNC press brakes are prepared for rapid tooling, which is an unquestionable consideration when you need to bend many small batches of parts.

Tooling

Even if you have a full shelf of tools, don’t assume that these tools will fit the newly purchased machine. Each tool must be checked for wear by measuring the length from the front of the punch to the shoulder and the length between the shoulders of the die.

For conventional tools, the deviation should be around ±0.001 inch per foot, and the total length deviation should not exceed ±0.005 inch. For precision-ground tools, the accuracy should be ±0.0004 inch per foot, and the total accuracy should not exceed ±0.002 inch. It is best to use precision-ground tools for CNC press brakes and conventional tools for manual press brakes.

Bend side length

Assuming a 90° bend along a 5×10-foot 10-gauge mild steel plate, the press brake must apply an additional 7.5 tons of pressure to lift the plate, and the operator must be prepared for a 280-pound straight edge drop. Making this part may require several strong workers or even a crane. Press brake operators often need to bend long-edge parts without realizing how strenuous their job is.

Safety operating procedures:

1. Strictly abide by the safety operating procedures for machine tool workers and wear labor protection equipment as required;

2. Before starting, carefully check whether the motor, switch, circuit and grounding are normal and firm, and check whether the operating parts and buttons of the equipment are stuck in the correct position;

3. Check the overlap and firmness of the upper and lower molds; check whether each positioning device meets the requirements of the processing;

4. When the upper slide and each positioning axis are not at the origin, run the return to origin program;

5. After the equipment is started, run it idle for 1~2 minutes, and the upper slide moves 2~3 times at full stroke. If abnormal sounds or faults are found, stop the machine immediately, eliminate the faults, and work only after everything is normal; 6. During work, one person should be in unified command, so that the operator and the feeding and pressing personnel can cooperate closely to ensure that the cooperating personnel are in a safe position before issuing the bending signal;

7. The sheet metal must be compacted when bending to prevent the sheet metal from bending. The material will be lifted up and hurt people;

8. When adjusting the sheet material pressing die, the power must be cut off and the operation must be stopped;

9. When changing the opening of the variable lower die, no material is allowed to contact the lower die;

10. When the machine tool is working, no one is allowed to stand behind the machine tool;

11. It is strictly forbidden to press and fold the sheet material at one end alone;

12. If the workpiece or die is found to be incorrect during operation, it should be stopped for correction. It is strictly forbidden to correct it by hand during operation to prevent injury to the hand;

13. It is forbidden to fold super thick iron plates or quenched steel plates, high-grade alloy steel, square steel and sheets that exceed the performance of the sheet bending machine to avoid damage to the machine tool;

14. Check the overlap of the upper and lower dies frequently; whether the indication of the pressure gauge meets the requirements;

15. Stop the machine immediately when an abnormality occurs, check the cause and eliminate it in time;

16. Before shutting down, place a wooden block on the lower die under the oil cylinders on both sides to lower the upper slide onto the wooden block;

17. Exit the control system program first, then cut off the power.

Factory Information:

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)

A bending machine is a machine that can bend thin plates. Its structure mainly includes a bracket, a workbench and a clamping plate. The workbench is placed on the bracket. The workbench consists of a base and a pressure plate. The base is connected to the clamping plate through a hinge. The base consists of a base shell, a coil and a cover plate. The coil is placed in the depression of the base shell, and the top of the depression is covered with a cover plate. When in use, the coil is energized by a wire, and after energization, an attractive force is generated on the pressure plate, thereby clamping the thin plate between the pressure plate and the base. Due to the use of electromagnetic force clamping, the pressure plate can be made into a variety of workpiece requirements, and can process workpieces with side walls, and the operation is also very simple.