Roll forming is a type of rolling that involves continuously bending long strips of metal sheet (typically coiled steel) into the desired cross-section.

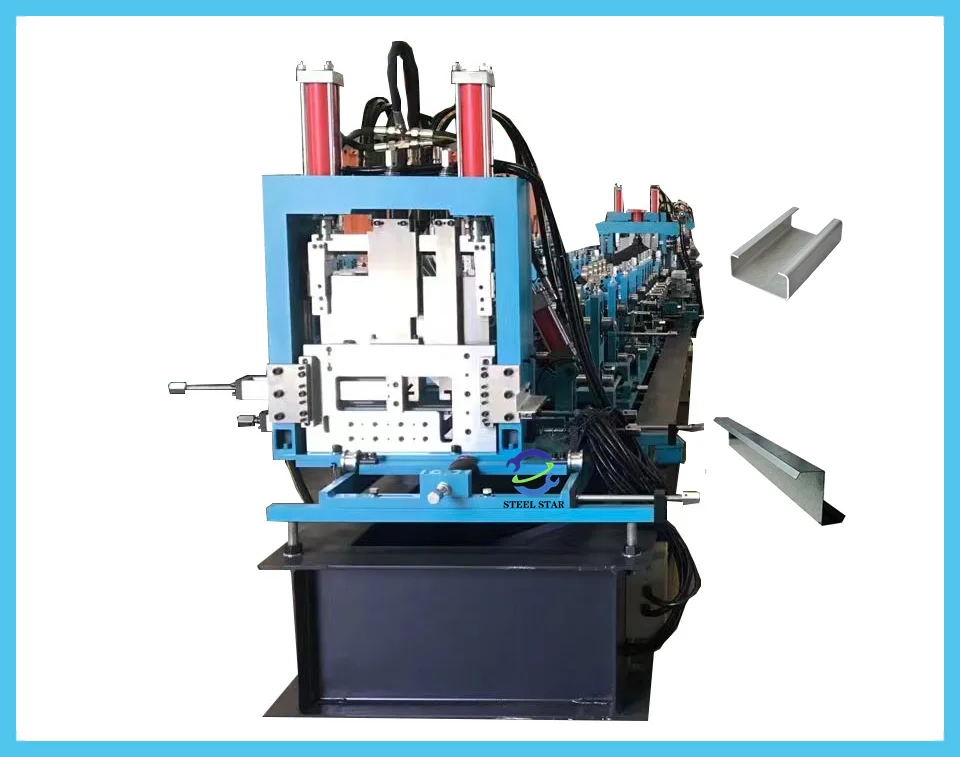

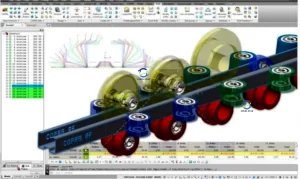

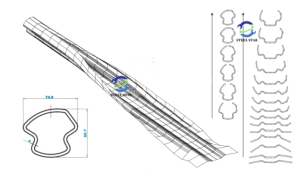

Design the mold shape and number of groups according to the required size. The shrinkage ratio of each group of cold bending is different. Through cold bending group by group, the final desired size can be achieved. Combined with electronic control system, hydraulic system, shearing system and counting encoder to realize automated operation.

Technical Parameters :

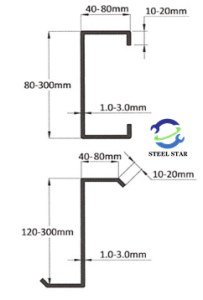

- Raw material width : 150mm — 600mm (Can be customized according to your needs)

- Thickness of sheet : 1.0mm — 3.0mm (Can be customized according to your needs)

- speed : 10 m — 30 m/min (Can be customized according to your needs)

- Voltage : 380v 50hz 3phase / 220v 60hz 3phase (Can be customized according to your needs)

- Language : English / Spanish / Arabic / Russian / Portuguese / German / French (Can be customized according to your needs)

- Material of rollers : Gcr15 / Cr12 / Cr12 Mov (Can be customized according to your needs)

- Motor brand : Siemens / other (Can be customized according to your needs)

- Electronic control PLC : Siemens / Delta / other (Can be customized according to your needs)

- Number of roller rows: According to product design

Application Scenarios :

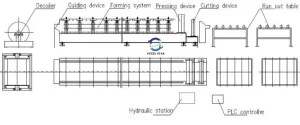

Equipment Production Line:

Related Product Information:

CZ steel is automatically processed and formed by CZ steel forming machine. CZ steel forming machine can automatically complete the forming process of CZ steel according to the given C steel size.CZ steel is widely used in purlins and wall beams of steel structure buildings, and can also be combined into lightweight roof trusses, brackets and other building components. In addition, it can also be used for columns, beams and arms in light machinery manufacturing.

The main differences between C-shaped steel and Z-shaped steel are as follows:

1. Different cross-sectional shapes and angles: The cross-sectional shape of C-shaped steel is C-shaped with an angle of 90 degrees; while the cross-sectional shape of Z-shaped steel is less than 90 degrees, usually between 60-75 degrees.

2. Mechanical properties and strength: The strength and stability of Z-shaped steel are generally good, while the mechanical properties of the strong and weak axes of C-shaped steel are quite different. When the roof slope is small, the bending section modulus of Z-shaped steel is slightly larger than that of C-shaped steel. When the roof slope increases, the utilization rate of the bending section modulus of Z-shaped steel symmetrical to the vertical direction increases.

3. Application scenarios: C-shaped steel is mostly used for light steel structures, such as walls; while Z-shaped steel is more used in scenarios that require higher strength and stability, such as roofs.

4. Connection method: The connection between C-shaped steel and steel frame is mostly bolted hinged, while the overlap of Z-shaped steel is more convenient.

In summary, there are obvious differences between C-shaped steel and Z-shaped steel in terms of cross-sectional shape, mechanical properties, strength and application scenarios.

Factory Information:

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)