Roll forming is a type of rolling that involves continuously bending long strips of metal sheet (typically coiled steel) into the desired cross-section.

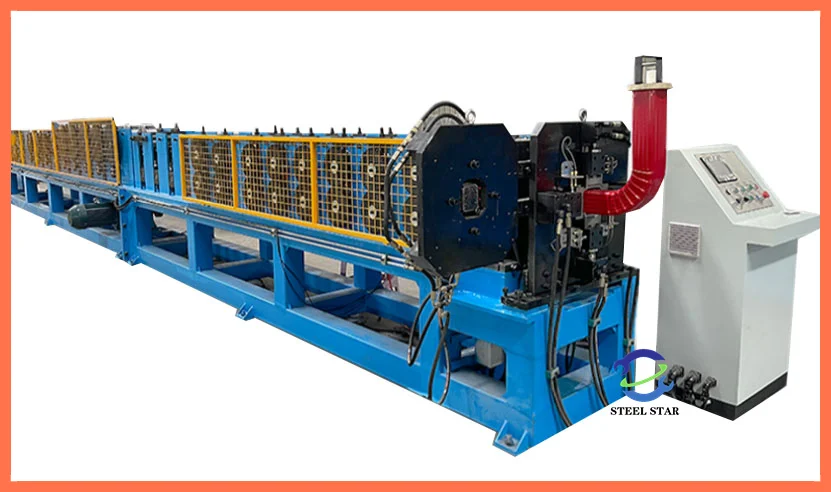

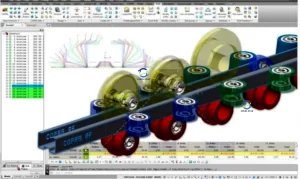

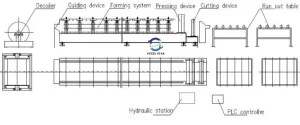

Design the mold shape and number of groups according to the required size. The shrinkage ratio of each group of cold bending is different. Through cold bending group by group, the final desired size can be achieved. Combined with electronic control system, hydraulic system, shearing system and counting encoder to realize automated operation.

Technical Parameters :

- Raw material width : 100mm — 600mm (Can be customized according to your needs)

- Thickness of sheet : 0.3mm — 1.0mm (Can be customized according to your needs)

- speed : 5 m — 20 m/min (Can be customized according to your needs)

- Voltage : 380v 50hz 3phase / 220v 60hz 3phase (Can be customized according to your needs)

- Language : English / Spanish / Arabic / Russian / Portuguese / German / French (Can be customized according to your needs)

- Material of rollers : C45 / Gcr15 / Cr12 / Cr12 Mov (Can be customized according to your needs)

- Motor brand : Siemens / other (Can be customized according to your needs)

- Electronic control PLC : Siemens / Delta (Can be customized according to your needs)

- Number of roller rows: According to product design

Application Scenarios :

Equipment Production Line:

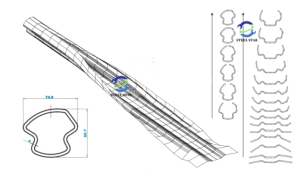

Related Product Information:

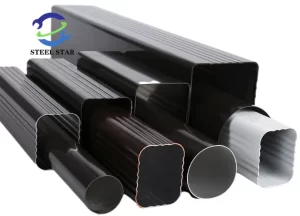

The pipes that collect rainwater from the roof are part of the downpipe system and are concentrated in the rainwater pipes laid below the ground.

Downpipe materials can be divided into: 1. Metal pipes (such as cast iron pipes, color aluminum pipes, copper pipes, color steel pipes, etc.); 2. Plastic pipes (such as PVC pipes, etc.).

Metal downpipes are more cost-effective.Downspouts made by pressing and bending color-coated coils.Color-coated steel downspouts are color-coated steel downspouts, which, as the name implies, are downspouts made by pressing and bending color-coated coils.

Purpose :

Collect rainwater from the roof and centrally direct it to the rainwater pipes laid below the ground. Rapid drainage reduces the accumulation of rainwater on the roof.

Material :

Color-coated steel downpipes, as the name suggests, refer to downpipes made by pressing and bending color-coated rolls.

Product features :

1. The application of steel downpipes makes the steel building more integrated. There are a variety of elbows to match the downpipes, and more complex walls are also suitable.

2. Compared with ordinary PVC pipes, it will not age and crack due to thermal expansion and contraction, so it is stronger and more durable.

3. Used in conjunction with steel buildings, it is simple and generous, with good visual effects.

4. Various supporting accessories meet various installation requirements.

Factory Information:

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)