Roll forming is a type of rolling that involves continuously bending long strips of metal sheet (typically coiled steel) into the desired cross-section.

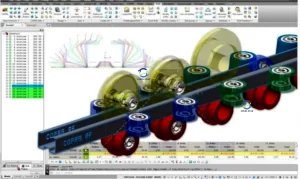

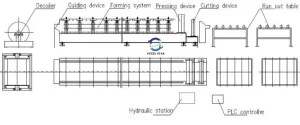

Design the mold shape and number of groups according to the required size. The shrinkage ratio of each group of cold bending is different. Through cold bending group by group, the final desired size can be achieved. Combined with electronic control system, hydraulic system, shearing system and counting encoder to realize automated operation.

Technical Parameters :

- Raw material width : 914mm / 925mm / 1000mm / 1200mm / 1220mm / 1250mm (Can be customized according to your needs)

- Thickness of sheet : 0.6mm — 1.6mm (Can be customized according to your needs)

- speed : 10 m — 30 m/min (Can be customized according to your needs)

- Voltage : 380v 50hz 3phase / 220v 60hz 3phase (Can be customized according to your needs)

- Language : English / Spanish / Arabic / Russian / Portuguese / German / French (Can be customized according to your needs)

- Material of rollers : C45 / Gcr15 / Cr12 / Cr12 Mov (Can be customized according to your needs)

- Motor brand : Siemens / other (Can be customized according to your needs)

- Electronic control PLC : Siemens / Delta (Can be customized according to your needs)

- Number of roller rows: According to product design

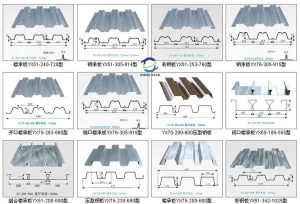

The pressed steel plate that supports the floor concrete is called a corrugated steel plate, also called a floor deck or steel deck.

The products are widely used in steel structure buildings such as power plants, power equipment companies, automobile showrooms, steel structure factories, cement warehouses, steel structure offices, airport terminals, railway stations, stadiums, concert halls, theaters, large supermarkets, logistics centers, Olympic venues and stadiums.

It can meet the requirements of rapid construction of the main steel structure, provide a firm working platform in a short time, and adopt the flow construction of laying corrugated steel plates on multiple floors and pouring concrete slabs in layers.

Application Scenarios :

Equipment Production Line:

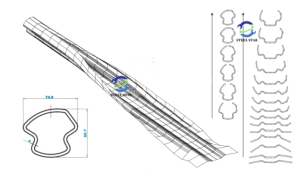

Related Product Layout Diagrams:

Classification of floor decking :

Open floor decking – Shrinking floor decking – Closed floor decking

Product application :

The product is widely used in power plants, power equipment companies, automobile showrooms, steel structure workshops, cement warehouses, steel structure offices, airport terminals, railway stations, stadiums, concert halls, theaters, large supermarkets, logistics centers, Olympic venues and other steel structure buildings.

It can meet the requirements of rapid construction of the main steel structure, provide a firm working platform in a short time, and adopt multiple floors to lay corrugated steel plates and pour concrete slabs in layers for continuous construction.

Main features :

1: It can meet the requirements of rapid construction of the main steel structure, provide a firm working platform in a short time, and adopt multiple floors to lay corrugated steel plates and pour concrete slabs in layers.

2: During the use stage, the floor decking is used as the tensile reinforcement of the concrete floor slab, which also improves the rigidity of the floor slab and saves the amount of steel bars and concrete.

3: The embossing on the surface of the corrugated plate makes the floor decking and concrete have the greatest bonding force, so that the two form a whole, and with stiffening ribs, the floor decking system has high strength bearing capacity.

4: Under cantilever conditions, the floor decking is only used as a permanent formwork. The length of the cantilever can be determined according to the cross-sectional characteristics of the floor decking. In order to prevent the cracking of the cantilevered plate, negative reinforcement should be provided at the support according to the design of the structural engineer.

In order to solve the many shortcomings of the first and second generation steel decking, such as the small net height of the building, engineers developed the third generation steel truss steel decking. The third generation floor decking is to change and reduce the convex high pressure type of the original floor decking, and use semi-automatic sheet metal welding equipment in the factory to process the steel bars in the floor slab into steel trusses to replace the convex height and bearing capacity of the floor decking. After welding, silanization, pure manganese phosphating, water washing, drying, galvanizing and other rust removal and anti-rust environmental protection process technologies are used to connect the steel truss and the floor decking in the factory with high-frequency resistance welding. The formwork system combines the steel bars in the concrete floor slab with the construction formwork to form a load-bearing component that can withstand the dead weight of wet concrete and construction loads during the construction stage, and the component can be used as a lateral support for the steel beam during the construction stage. During the use stage, the steel truss works together with the concrete to withstand the use load.

Factory Information:

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)

The pressed steel plate that supports the floor concrete is called a corrugated steel plate, also called a floor deck or steel deck.

In the modern construction industry, the floor decking machine is a key equipment widely used in the production of steel structure floor decking. Its main functions include automatic unwinding and feeding, forming and cutting, conveying code segments, etc., and it has gradually developed from traditional production methods to modern ones. Today, we will introduce several floor decking machines suitable for different market needs in detail, including models customized for the Brazilian and Saudi markets, and give you an in-depth understanding of their evolution, characteristics and technical advantages.