Roll forming is a type of rolling that involves continuously bending long strips of metal sheet (typically coiled steel) into the desired cross-section.

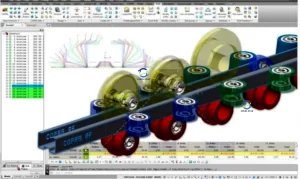

Design the mold shape and number of groups according to the required size. The shrinkage ratio of each group of cold bending is different. Through cold bending group by group, the final desired size can be achieved. Combined with electronic control system, hydraulic system, shearing system and counting encoder to realize automated operation.

Technical Parameters :

- Raw material width : 500mm — 1000mm (Can be customized according to your needs)

- Thickness of sheet : 1mm — 3mm (Can be customized according to your needs)

- speed : 5 m — 20 m/min (Can be customized according to your needs)

- Voltage : 380v 50hz 3phase / 220v 60hz 3phase (Can be customized according to your needs)

- Language : English / Spanish / Arabic / Russian / Portuguese / German / French (Can be customized according to your needs)

- Material of rollers : Gcr15 / Cr12 / Cr12 Mov (Can be customized according to your needs)

- Motor brand : Siemens / other (Can be customized according to your needs)

- Electronic control PLC : Siemens / Delta / other (Can be customized according to your needs)

- Number of roller rows: According to product design

Application Scenarios :

Related Product Information:

The high-speed guardrail uses the deformation of the soil base, columns and beams to absorb the collision energy, and forces the out-of-control vehicle to change direction and return to the normal driving direction, preventing the vehicle from running off the road, thereby protecting the vehicle and passengers and reducing the losses caused by the accident.

1. The installation of the column must be carried out under the premise of strengthening the earth shoulder, and it is set on bridges, passages and large-span culvert structures. During the installation of the guardrail board in the main project, the flange and anchor bolts should be processed first for the installation of the column.

2. Make good construction preparations and detailed construction organization. The installation tools include: pile driver, excavation tools, tamping tools, pliers, hammer and measuring tools such as theodolite, level, tape measure, etc.

3. When constructing the corrugated guardrail, the data of various facilities should be accurately mastered, especially the precise location of various pipelines buried in the roadbed. During the construction process, no damage to underground facilities is allowed.

Column layout:

1. Layout the columns according to the design drawings, and use bridges, passages, culverts, interchanges, level crossings, etc. as control points for distance measurement and positioning. When measuring distance, put the unit at the lowest position.

2. When staking out the columns, the spacing can be adjusted using the adjustment section, and the number of zeros in the spacing can be handled using the allocation method.

3. After the column is laid out, the foundation status of each column position should be investigated. If there are underground communication pipelines, drainage pipes, etc., or the buried depth of the top of the culvert is insufficient, the position of some columns should be adjusted or the concrete foundation should be used for fixing.

Column installation:

1. The column installation should be consistent with the design drawing and coordinated with the road line shape.

2. The column should be firmly buried in the soil to the designed depth and perpendicular to the road surface.

3. For general sections, the column can be constructed by the driving method. The construction should be accurately positioned. When the driving is too deep, the column shall not be partially pulled out for correction. It must be pulled out completely and re-driven after the foundation is compacted.

4. When the driving method cannot be used for construction, the drilling construction process can be used. If the fill height of the bridge and culvert structure cannot meet the driving depth required for the column, the concrete foundation fixing method shall be adopted.

5. After the column is installed in place, its horizontal and vertical directions should form a smooth line shape.

6. The columns at the gradient section and end of the guardrail should be installed according to the coordinates specified in the design.

7.⑦ Because the road surface is constructed in two phases, when installing the guardrail, follow the reserved holes for the columns indicated in the design drawings, and install and raise the height of the corrugated guardrail according to the construction sequence of the first and second phases of the road surface.

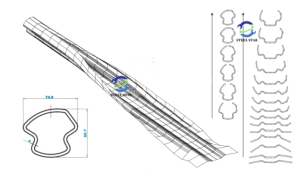

Common types

Installation of corrugated guardrail:

1. The corrugated guardrail panels are spliced together by splicing bolts and fixed to the columns or beams by connecting bolts.

2. The connecting bolts and splicing bolts of the corrugated guardrail panels should not be tightened too early, so that they can be adjusted in time during the installation process using the oblong holes of the corrugated beams to form a smooth line shape and avoid local bumps.

3. The top surface of the corrugated guardrail panel should be coordinated with the vertical curve of the road. When the line shape of the corrugated guardrail is considered satisfactory, the bolts can be tightened for the last time.

Technical specifications of corrugated guardrail

(1) Double wave: length 4320mm, plate width 310mm, wave depth 85mm, plate thickness 3mm/4mm.

Triple wave corrugated guardrail panel: length 4320mm, plate width 506mm, wave depth 85mm, plate thickness 4mm.

(2) Round: diameter 140/114mm, column wall thickness 4/4.5mm.

Square column: side length 130mm, column wall thickness 6mm.

Column length 1200mm/1500mm/1800mm/2150mm, etc.

(3) Column cap: thickness 2/3mm, hole spacing 100/150mm, diameter 114/140mm.

(4) Block: 196*178*200mm, thickness 3/4/4.25/4.5mm.

Bracket: length 300mm, width 70mm, thickness 4mm/4.5mm.

(5) Bolt: M16*170 / M16*150 / M16*50 / M16*42 / M16*35

Factory Information:

# Highway Guardrail Roll Forming Machine,Guardrail Roll Forming Machine,Steel Highway Guardrail Rollformer,2 & 3 Waves Guardrail Roll Forming Machine,Highway Guardrail Machine,Waves Metal Highway Guardrail Sheet Crash Barrier Roll Forming Machine,China Highway Guardrail Roll Forming Machine,China Guardrail Roll Forming Machine,China Steel Highway Guardrail Rollformer,China 2 & 3 Waves Guardrail Roll Forming Machine,China Highway Guardrail Machine,China Waves Metal Highway Guardrail Sheet Crash Barrier Roll Forming Machine.

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)