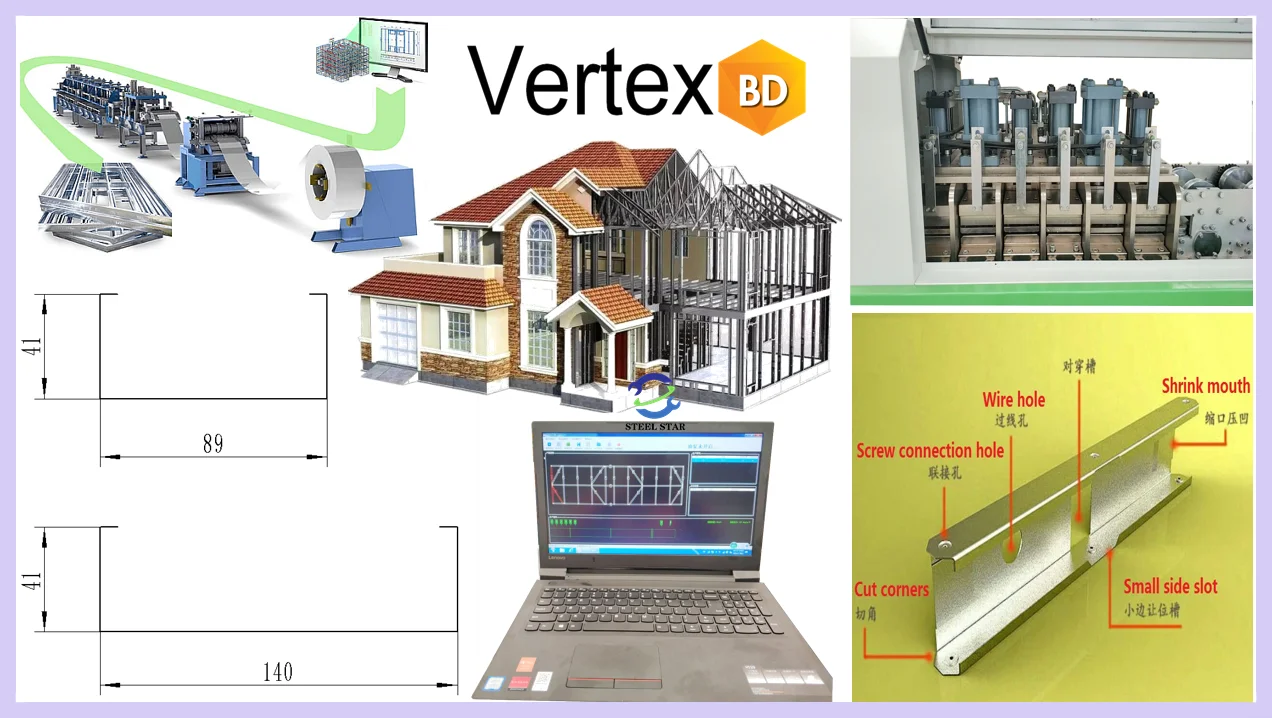

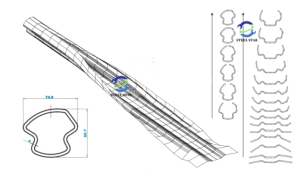

Roll forming is a type of rolling that involves continuously bending long strips of metal sheet (typically coiled steel) into the desired cross-section.

Design the mold shape and number of groups according to the required size. The shrinkage ratio of each group of cold bending is different. Through cold bending group by group, the final desired size can be achieved. Combined with electronic control system, hydraulic system, shearing system and counting encoder to realize automated operation.

Technical Parameters :

- Raw material width : 178mm — 235mm (Can be customized according to your needs)

- Thickness of sheet : 0.7mm — 1.0mm G550 (Can be customized according to your needs)

- speed : 5 m — 20 m/min (Can be customized according to your needs)

- Voltage : 380v 50hz 3phase / 220v 60hz 3phase (Can be customized according to your needs)

- Language : English / Spanish / Arabic / Russian / Portuguese / German / French (Can be customized according to your needs)

- Material of rollers : Gcr15 / Cr12 / Cr12 Mov (Can be customized according to your needs)

- Motor brand : Siemens / other (Can be customized according to your needs)

- Electronic control PLC : Siemens / Delta / other (Can be customized according to your needs)

- Number of roller rows: 12-14 Rows

Application Scenarios :

Related Product Information:

Light steel villas, also known as light steel structure houses, are mainly made of light steel keels synthesized by hot-dip galvanized aluminum steel strips through cold rolling technology.

Light Steel Characteristics Report Editor:

1. Corrosion Resistance The corrosion resistance of “55% Al-Zn Coated Steel Coil” comes from the barrier layer protection function of aluminum and the sacrificial protection function of zinc. When zinc is used as sacrificial protection on the cut edges, scratches and coating abrasions, aluminum forms an insoluble oxide layer to play a barrier protection function. Al-Zn Coated Steel Coil has been subjected to outdoor exposure tests for more than 20 years in various atmospheric environments, proving that the cut edge protection function of 55% Al-Zn Coated Steel Sheet is better than that of galvanized steel sheet and 5% Al-Zn Coated Steel Sheet.

2. Heat Resistance The heat resistance of 55% Al-Zn Coated Steel Sheet is better than that of galvanized steel sheet, and is similar to that of Al-Zn Coated Steel Sheet in high temperature oxidation resistance. Al-Zn Coated Steel Sheet can be used in high temperature environments up to 315 degrees.

3. Reflectivity The 55% Al-Zn Coated Steel Sheet has a high reflectivity, making it a heat-resistant barrier; the heat reflectivity of Al-Zn Coated Steel Sheet is almost twice that of galvanized steel sheet, so it can also achieve energy-saving effects when used as roofs and panels without painting.

4. Paintability: Since the zinc layer of the galvanized steel sheet has excellent adhesion to the paint, it can be painted without pretreatment and weathering when used as a sign board for general purposes; while galvanized steel sheets require weathering and pretreatment.

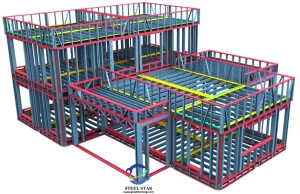

Light steel villa system structure:

The light steel wall structure system is jointly stressed by light steel ribbed beams and columns and conforming maintenance structures. It has excellent physical performance indicators, short construction period, and good insulation effect. It is a new type of green, energy-saving and environmentally friendly building structure system.

1. Foundation system

The self-weight of light steel structure houses is light, only about one-fifth of brick-concrete structure houses and about one-eighth of reinforced concrete structure houses. Therefore, it can greatly reduce the cost of foundation construction. The foundation of light steel structure houses generally adopts strip foundation.

① The self-weight of light steel structure is light, which can greatly reduce the cost of foundation engineering;

② The moisture-proof design of the foundation effectively prevents moisture and harmful gases from invading;

③ Reasonable anchoring method ensures reliable connection between the foundation and the main body.

2. Wall system

The exterior wall system is generally between 120-200㎜. Due to the thin wall, the actual use area of light steel structure houses is about 10%-15% higher than that of traditional houses, and the indoor use area is increased by more than 90% compared with traditional houses. The indoor space can be flexibly divided. Pipelines can be arranged in the holes reserved in the walls, floors and roof components, which are well concealed and more beautiful.

① The wall is filled with glass fiber wool, which has good thermal insulation, heat insulation and sound insulation performance;

② The breathing paper is waterproof and breathable, which can effectively adjust the indoor air humidity, make living more comfortable, and effectively prevent mold from growing inside the wall;

③ The pipeline is buried in the wall and does not occupy indoor space.

3. Floor system

The floor is composed of high-strength hot-dip galvanized C-type and U-type light steel components. The floor beams are arranged with dense ribs at equal intervals according to the standard modulus. The floor beams are covered with structural plates that have been strictly moisture-proof and anti-corrosion to form a solid and earthquake-resistant floor system.

① The combined structure of the structural plate and the floor steel beam is solid and stable;

② Various water and electricity pipelines are concealed in the floor structure and do not occupy the building floor height;

③ Filling the interlayer with glass fiber wool has significant effects of thermal insulation, sound absorption and sound insulation.

4. Roof system

The roof truss is assembled from various light steel components, generally triangular trusses and T-shaped trusses, which can easily and flexibly realize various complex roof shapes. Generally, the roof uses colorful asphalt tiles, which have good waterproof performance, highlighting beauty and quality.

① The composite roof has functions such as rainproof, weather-resistant, and heat-insulating, and can achieve rich and diverse shapes;

② Ventilation circulation design keeps the air fresh at all times.

5. Structural components

All structural components are made of high-strength galvanized steel to ensure the service life of the house. All structural components are cold-pressed by the factory’s precision mechanical assembly line, and the dimensional accuracy is measured in millimeters, which is unmatched by other structures.

Factory Information:

Website:

www.greatforming.com (English)

www.arabicgreatforming.com (عربي)

www.russiangreatforming.com(Русский)

www.spanishgreatforming.com(Español)

www.frenchgreatforming.com(Français)

www.portuguesegreatforming.com(Portuguese)